Laser Welding Stainless Steel

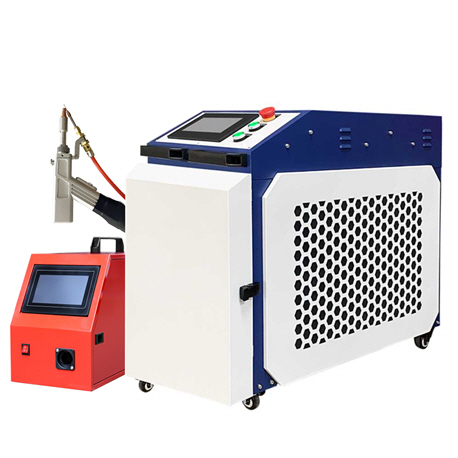

2025-07-07With the continuous pursuit of production efficiency and product quality in the manufacturing industry, handheld laser welding machines have gradually become an important tool in the field of industrial welding. Its strong flexibility, easy operation and wide range of applications make it widely used in many industries such as electronics, hardware, and auto parts. This article will explore the successful application cases of handheld laser welding of stainless steel sheets, pipes and workpieces, and analyze its advantages and precautions in actual operation.

I. Working Principle & Applications of Handheld Laser Welder in Welding Stainless Steel

Handheld laser welder uses high-energy laser beam as heat source, and realizes the melting and connection of materials by precisely controlling the interaction between laser beam and material. This technology has the characteristics of high precision, high speed and high quality, so it has a wide range of applications in the field of stainless steel welding. Stainless steel, as a common metal material, has good corrosion resistance and mechanical properties, and is widely used in various industrial fields. The emergence of handheld laser welding machine provides an effective solution for the precision welding of stainless steel.

In the practical application occasions, the operator can weld stainless steel with handheld laser welder, which makes the welding process more flexible and convenient. At the same time, due to the non-contact nature of laser welding, problems such as electrode wear and impurity contamination in traditional welding are avoided, thus ensuring the quality and performance of the weld. Therefore, handheld laser welding machines are used in various fields, including laser welding of stainless steel sheets, pipes and workpieces in industries such as kitchens & bathrooms, elevators, shelves, hardware, building materials, doors & windows, manhole covers, crafts, engineering machinery, boating and etc., and have won market recognition with their effectiveness and stability. The following video shares a customer of NITRATEK is using our handheld laser welding machine to weld stainless steel pipes on site:

II. Advantages of Handheld Laser Welding Machine in Stainless Steel Welding

1. High-precision welding: the diameter of the laser beam can be as small as microns, so high-precision welding can be achieved. This is especially important for stainless steel components that require precision connection. Laser welding can form smooth and uniform welds without the use of filler materials, and is particularly suitable for applications with high surface finish requirements. When welding stainless steel, the high-temperature area generated by laser welding is small, which helps to reduce the formation of chromium oxide layer and maintain good weld appearance and performance.

2. Small heat-affected zone: due to the extremely high energy density of the laser beam, the welding process can be completed in a very short time, which greatly reduces the diffusion of heat to the surrounding stainless steel materials, reduces the size of the heat-affected zone, and helps to preserve the original properties of the stainless steel material.

3. Small welding deformation: rapid heating and cooling during laser welding can effectively reduce welding deformation and improve product quality. Because low heat input means that the workpiece is less heated, the deformation after welding is relatively small, which is particularly suitable for welding stainless steel sheets or precision parts.

4. Welding of hard-to-reach parts: the portability and flexibility of the handheld laser welder make it easy to weld the hard-to-reach parts of stainless steel sheets, improving the convenience of welding. It enables the operator to flexibly deal with various complex shapes and hard-to-reach locations, expanding the scope of application.

5. Improve production efficiency: compared with traditional welding methods such as TIG or MIG welding, handheld laser welding machines have higher welding speeds in welding stainless steel pipes, sheets and other workpieces, so they can effectively improve production efficiency.

III. Precautions for Welding Stainless Steel with Handheld Laser Welders

Although handheld laser welders have many advantages in welding stainless steel, the following precautions should still be taken during operation:

1. Safe operation: the laser beam generated during laser welding is harmful to the human body. The operator needs to wear professional protective glasses and gloves with appropriate optical density during welding. These devices can effectively protect the operator from laser radiation and other potential hazards. In addition, the operator should weld stainless steel in a well-lit and well-ventilated work area, avoid operating near flammable items, and ensure the safety of the working environment.

2. Parameter setting: according to the type, thickness and required welding depth of stainless steel materials, the laser power, pulse width, frequency and other parameters should be reasonably set to accurately control the laser energy and ensure the consistent quality of each weld point to obtain the best welding effect. Different stainless steel grades may require different settings.

3. Material preparation: the stainless steel surface should be thoroughly cleaned before welding to remove oil, oxides and other impurities, as these contaminants will affect the welding quality and cause problems such as pores or cracks. For thicker plates, the weld edges may need to be properly chamfered to increase the weld strength and promote good fusion.

4. Welding sequence and speed: for stainless steel components with complex structures, the welding sequence should be reasonably planned to reduce welding deformation and internal stress. The operator should reasonably control the welding speed: too fast speed may result in an insufficiently melted joint, while too slow speed will cause overheating and deformation. It is very important to find the best speed for specific materials and thicknesses.

5. Quality inspection: after welding, the weld should be inspected for quality, including appearance inspection, non-destructive testing, etc., to ensure that the welding quality meets the requirements. Remove spatter and residues around the welding area in time, and polish if necessary to achieve the required appearance requirements.

In summary, handheld laser welding machines can efficiently weld stainless steel materials and show significant advantages in terms of accuracy, efficiency and weld quality. During operation, operators must strictly abide by relevant safety regulations and operating guidelines to ensure welding quality and personnel safety. With the continuous advancement of laser welding technology, the application prospects of laser welding in the field of stainless steel will be broader, and it will also bring more innovative possibilities to various industries.