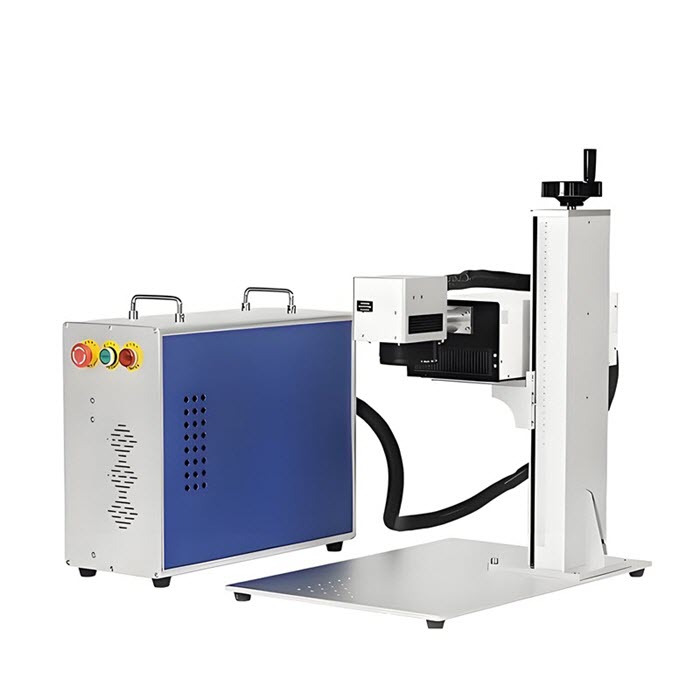

3w 5w 10w Flying UV Laser Marking Machine

M13 series flying UV laser marking machine provides three power options: 3W, 5W and 10W, to meet diverse production needs. The equipment has high-precision, high-speed and high-quality marking capabilities, and is particularly suitable for various high-speed automated production lines, which can significantly improve overall operating efficiency. M13 flying UV laser marker is widely used in online marking of product identification, such as clear engraving of serial numbers, batch numbers, production dates, text descriptions, barcodes, QR codes and other information. The marking results are long-lasting and clear, with excellent recognition effect and stability.

- • Laser power: 3w, 5w, 10w

- • Beam diameter: <1.2mm

- • Marking area: 70*70~300*300mm

- • Minimum line width: 0.01~0.05mm

- • Processed materials: plastic, glass, metal, ceramic, silicon wafer, leather

- Information

- Specification

- Application

| Item | M13-03 | M13-05 | M13-10 |

| Supply voltage | 110v/220v, 50/60Hz | 110v/220v, 50/60Hz | 110v/220v, 50/60Hz |

| Overall power consumption | <1000w | <1000w | <1000w |

| Cooling method | Air/ water cooling | Air/ water cooling | Water cooling |

| Laser output power | 3w | 5w | 10w |

| Laser light source | RFH/ HAN's/ PulseX | RFH/ HAN's/ PulseX | RFH/ HAN's/ PulseX |

| Laser wavelength | 355nm | 355nm | 355nm |

| Beam diameter | <1.2mm | <1.2mm | <1.2mm |

| Marking area | 70*70~110*110mm | 70*70~200*200mm | 70*70~300*300mm |

| Minimum line width | 0.01~0.05mm | 0.01~0.05mm | 0.01~0.05mm |

| Minimum character | 0.1mm | 0.1mm | 0.1mm |

| Marking depth | 0.01~0.1mm | 0.01~0.15mm | 0.01~0.2mm |

| Max. marking speed | 7000mm/s | 7000mm/s | 7000mm/s |

| Cable length | 1.5m (cable length and plugs can be customized) | 1.5m (cable length and plugs can be customized) | 1.5m (cable length and plugs can be customized) |

| Working environment | -10℃~40℃ | -10℃~40℃ | -10℃~40℃ |

NITRATEK flying UV laser marking machine supports highly free adjustment, which is convenient for adapting to different working conditions and operating requirements. The entire marking process is clean and environmentally friendly, does not produce any chemical pollution or harmful substances, and fully meets the standards of modern green manufacturing.

The equipment adopts a split structural design to effectively isolate each functional module, reduce mutual interference, and improve overall operational stability. According to the actual processing needs of customers, it can be equipped with an independent water cooling system, which can accurately control the working temperature of the laser and the marking head to ensure that the equipment still maintains good performance under high-intensity operation.

The laser system has an intelligent speed regulation function, excellent anti-electromagnetic interference ability and an efficient thermal management system to ensure the reliability of long-term continuous work.

The operation interface adopts a humanized graphical design. Users can understand the equipment status, parameter settings and operation procedures through an intuitive screen, which greatly improves the convenience of use and work efficiency. Equipped with a large-size touch screen, it provides a clear and friendly interactive experience. Users can complete parameter adjustment and function settings by simply touching or sliding. The screen displays the operating status of the equipment in real time, including key information such as marking progress, temperature changes, and voltage conditions, which is convenient for timely grasp of equipment dynamics and prevention of potential failures.

M13 flying UV laser marking machine has a simple design of intelligent control panel and intuitive operation. The whole machine is compact and lightweight, easy to install and move, and is particularly suitable for application environments with limited space. Compared with traditional models, the machine's water cooling system runs more quietly and the spindle heat dissipation is more efficient, further improving the stability and service life of the equipment.

The Flying UV laser marking machine is a high-precision marking device based on UV laser technology, which is particularly suitable for continuous production environments that require efficient, accurate and high-quality marking. Its non-contact processing method and stable performance make it an ideal choice for large-scale operations in many industries.

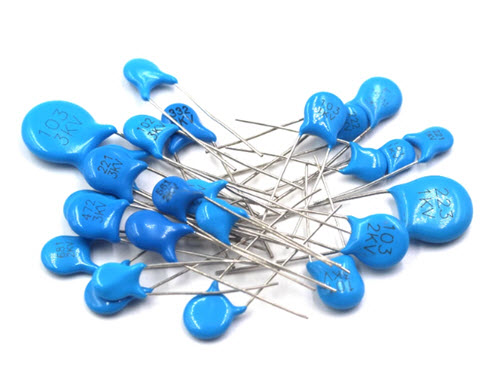

In the field of electronic manufacturing, this device is widely used for the identification of various precision components, such as smartphone casings, computer accessories, circuit boards and micro-electronic parts, and can clearly engrave information such as models, serial numbers and brand logos.

In the medical industry, the Flying UV laser marking machine is often used for permanent marking of surgical instruments, diagnostic equipment and various medical devices, including batch numbers, production dates, QR codes and anti-counterfeiting labels, etc., to ensure that the information is clear and readable without affecting the cleanliness and durability of the equipment itself.

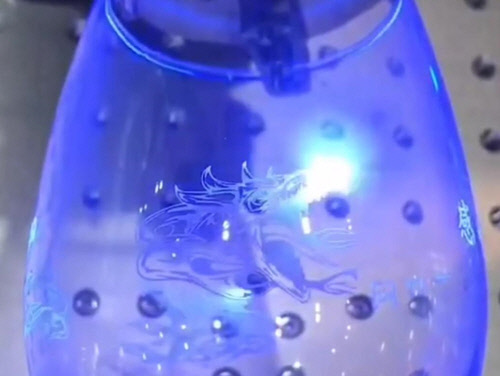

The food packaging industry also benefits from the wide application of this technology, which is suitable for high-speed online marking of packaging materials such as plastic bottles, glass bottles, metal cans and cartons, and can achieve clear and compliant product information identification, such as shelf life, batch codes and tracking codes.

In addition, in the jewelry and luxury goods industry, the equipment is used to finely engrave brand logos, style numbers, material identification and other content on valuable items. It is especially suitable for surface micro-carving of precious metals such as gold, silver, platinum, and materials such as crystal and ceramics, ensuring exquisite details and not easy to wear.

With its excellent marking quality and wide adaptability, the flying UV laser marking machine has become one of the indispensable key tools in modern intelligent manufacturing.