Wire Marking with UV Wire Laser Marker

2025-09-17In modern industrial manufacturing, wire products such as cables, wires, and optical fibers are widely used in communications, power generation, automotive, construction, and consumer electronics. Clear, durable marking of wire surfaces is crucial for product traceability, quality control, brand identification, and anti-counterfeiting and anti-channeling efforts. With technological advancements, laser marking machines are gradually replacing traditional inkjet marking machines and becoming the mainstream tool for wire marking.

Working Principle of Wire Laser Marking

Wire laser marking is a non-contact processing technology. Its core principle is to focus a high-energy-density laser beam on the surface of the wire. Through thermal or photochemical effects, the surface layer undergoes a color change, vaporization, or microstructural modification, thereby forming a permanent mark.

In practical applications, the wire is typically moved at a constant speed via a conveyor belt or traction device. Laser marking systems are equipped with high-precision sensors (such as photoelectric encoders or visual triggers) to capture the wire's position and speed in real time. The control system synchronizes the laser's motion based on this information, accurately marking characters, barcodes, QR codes, logos, and other information during the process. This process, known as "flying marking," can be seamlessly integrated into production lines, enabling high-speed automated marking.

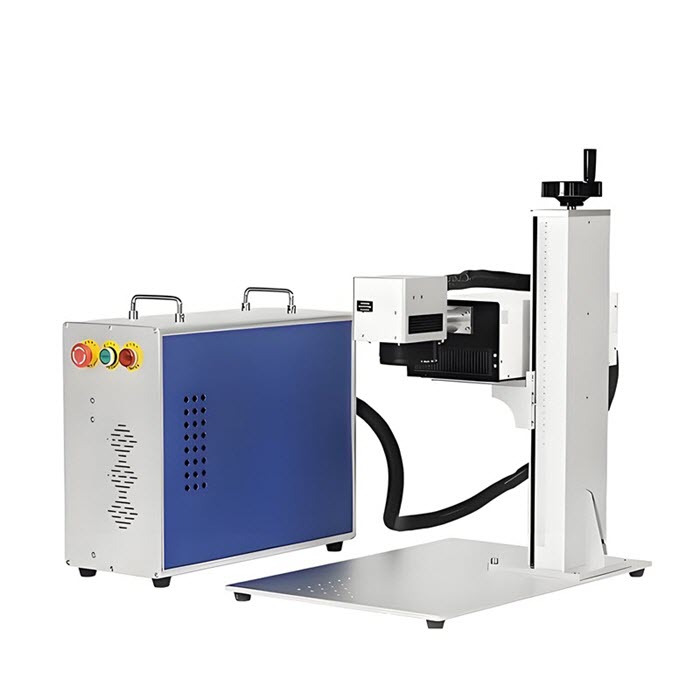

Wire laser marking technology mainly uses UV laser marking machines to directly break the molecular chains of substances on the surface of the material through short-wavelength lasers, thereby displaying information on the corresponding track. It is also suitable for fine marking on curved surfaces on the surface of wires without damaging the wire core or causing mechanical and thermal deformation of the wire itself.

Significant Advantages of Laser Marking Over Traditional Inkjet Marking

Compared to traditional inkjet coding technology, laser marking offers overwhelming advantages in many aspects of wire marking:

▪ Marking Permanence and Durability

Laser marking directly creates a physical or chemical change on the surface of the cable material, blending the mark with the material and providing exceptional resistance to wear, corrosion, heat, and solvents. Even under harsh conditions and long-term use, it will not fade, peel, or blur. Inkjet marking, on the other hand, is easily rubbed, dissolved by solvents, or faded by UV exposure, posing a risk of information loss.

▪ Environmentally Friendly and Consumable-Free

Laser marking of cables requires no chemical consumables such as inks and solvents, and produces no volatile organic compounds (VOCs) or waste liquids, truly achieving green and clean production. Inkjet systems, on the other hand, require constant refilling of ink and cleaning fluids, increasing operating costs and creating environmental and safety risks.

▪ High Precision and High Definition

Laser marking enables micron-level precision marking, resulting in sharp, crisp edges for characters and QR codes and high recognition rates. It is particularly suitable for marking small wires or densely packed information. Inkjet marking is prone to ink droplet spread, line breakage, or blurring, which can affect readability.

▪ Low operating costs and easy maintenance

Laser systems require no consumables, requiring only regular maintenance of optical components. Long-term operating costs are significantly lower than inkjet systems, which require ongoing purchases of ink cartridges and cleaning fluids. Laser systems are also compact, have a low failure rate, and require minimal maintenance.

▪ High production efficiency and easy integration

Wire and cable laser marking offers high speeds, making it a perfect match for high-speed extrusion lines, enabling in-line simultaneous marking and improving overall production cycle times. Its digital control system facilitates integration with information systems such as MES and ERP, enabling data traceability and intelligent management.

Practical Applications of Laser Marking in Various Industries

▪ Wire and Cable Industry

Wire laser marking machines can be used to mark wire model, specification, voltage level, manufacturer, production date, meter count, and other information. Laser marking can clearly mark various insulation materials such as PVC, XLPE, and PE, meeting the high standards required for power, construction, and industrial wiring.

▪ Communications and Fiber Optic Industries

Wire laser markers can also mark serial numbers, lengths, customer information, and QR codes on fiber bundles, network cables, and coaxial cables, enabling full traceability. Laser marking does not damage the fiber core, ensuring signal transmission quality.

▪ Automotive Wiring Harness Manufacturing

Automotive wiring harnesses are complex, requiring extremely high oil and high-temperature resistance. Laser marking maintains stability in high-temperature environments, ensuring clear and legible markings, facilitating automated assembly and quality traceability.

▪ Consumer Electronics and Home Appliances

Wire laser marking is also widely used to add brand logos, certification marks, and safety information to products such as headphone cables, charging cables, and power cords, enhancing product quality and preventing counterfeiting.

▪ Medical Wire

Wire laser marking machines provide sterile, contamination-free, permanent marking on products such as medical catheters and sensor cables, meeting the strict hygiene standards of the medical industry.

Wire laser marking technology, thanks to its permanence, environmental friendliness, high precision, and high efficiency, has become an indispensable key process in modern wire manufacturing. With the decreasing cost of lasers and the widespread adoption of intelligent control systems, laser marking is rapidly replacing traditional inkjet technology, driving wire marking towards higher quality, greater automation, and greater sustainability. In the future, with the integration of technologies such as ultrafast lasers and intelligent vision guidance, wire laser marking machines will achieve even greater breakthroughs in precision, adaptability, and intelligence, providing solid support for intelligent manufacturing in the Industry 4.0 era.