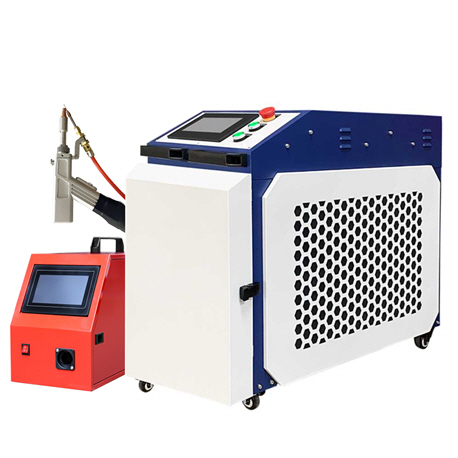

100w 200w Desktop Laser Jewelry Spot Welding Machine

NITRATEK W03 series laser spot welding machine is designed for high-precision welding needs and is suitable for a variety of processes such as gold and silver jewelry welding, golf club head welding, electronic component hole filling, sand hole filling, and inlay connection. Its welding effect is firm and reliable, the finished product has a delicate appearance, is not easy to deform, and has a friendly operation interface, a low learning threshold, and is easy to get started quickly. It is an ideal equipment choice for all kinds of fine welding operations.

- • Laser power: 100w, 200w

- • Welding depth: 0.1~2.0mm

- • Wavelength: 1064nm

- • Spot adjustment range: 0.2~2mm

- • Processed materials: gold, silver, stainless steel, titanium alloy

- Information

- Specification

- Application

| Item | W03-100/ W03-200 |

| Maximum laser power | 100W/200W |

| Laser wavelength | 1064nm |

| Max energy of single pulse | 90J/120J |

| Laser welding depth | 0.1~2.0mm |

| Pulse width | 0.1~15ms |

| Laser welding frequency | 1~20Hz |

| Adjustable range of spot size | 0.2~2mm |

| Control system | Industrial computer |

| Machine power consumption | ≤3kw |

| Power requirement | 220V±10%/ 50Hz/ 30A |

| System composition | Host computer, cold water tank |

| Consumables | Xenon lamp, filter, protection lens, argon gas |

| Environment | clean, no dust or less dust |

| Temperature | 55℉ (13℃) to 82℉ (28℃) |

| Humidity | 5% to 75% non-condensing |

| Power | 220V/ 50HZ AC, 30A air switch, stable voltage |

NITRATEK's carefully crafted W03 laser spot welder is designed for hole filling and sand hole repair of gold and silver jewelry. The equipment uses advanced laser heat conduction technology to accurately heat the surface of the workpiece through a high-energy laser beam, and the heat diffuses from the surface to the inside to achieve efficient welding. By accurately adjusting key parameters such as laser pulse width, energy density, peak power and frequency, the molten pool morphology and depth can be effectively controlled to ensure that the welding is firm, fine and non-deformed. With its high precision and stability, it has been widely used in the field of gold and silver jewelry manufacturing and welding of micro-precision parts, and is deeply favored by the industry.

• Multi-dimensional adjustment function: You can flexibly adjust the energy intensity, pulse width, working frequency and spot size to adapt to various welding needs and easily achieve ideal welding effects. All parameters are operated through the adjustment lever in the closed control chamber, with a simple structure, precise control and rapid response.

• The optical system adopts the original British imported ceramic focusing cavity: it has excellent high temperature resistance and corrosion resistance, and significantly improves the photoelectric conversion efficiency. The focusing cavity has a design life of up to 8 to 10 years, and with a high-durability xenon lamp, the service life exceeds 8 million times, which greatly reduces the maintenance frequency.

• Integrates the world's leading intelligent shading technology: it can automatically switch the protection mode according to the working status, effectively shield strong light stimulation, ensure the eye safety of operators, and improve the comfort of operation.

• Stable continuous operation performance: The whole machine supports all-weather continuous operation, with excellent stability and reliability, ensuring excellent performance under long-term high-intensity use, and can reach 10,000 hours of maintenance-free operation under normal use.

• Optimized design and user interface: The body structure has been professionally ergonomically optimized, with a user-friendly interface and a reasonable layout, which facilitates long-term stable operation, significantly reduces fatigue, and improves work efficiency and user experience.

Overall, the NITRATEK W03 series jewelry laser welding machine demonstrates superior process performance with its fast processing speed, efficient operation capability, and deep-melting welding effect. During operation, the equipment has a small heat-affected range, slight deformation of the workpiece, stable and reliable welding quality, and clean and pollution-free welds, fully meeting the high requirements for details in precision jewelry processing. At the same time, the whole machine is compactly designed and small in size, which is easy to operate and space layout. It has the advantages of environmental protection, high efficiency, and energy saving, and is an ideal welding solution in the field of modern precision manufacturing.