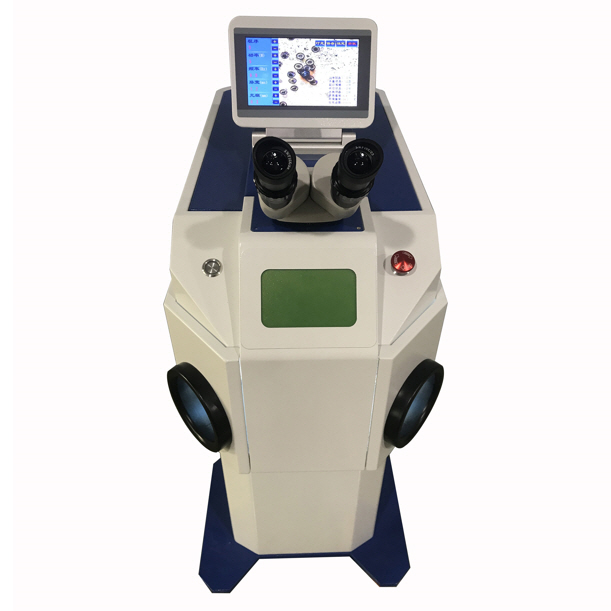

200w Vertical Laser Gold Spot Welding Machine

NITRATEK W04-200 vertical laser gold spot welding machine is designed for hole repair, sand hole repair and inlay welding of precision parts such as gold and silver jewelry, golf clubs, and electronic components. It is suitable for high-quality connection requirements of various subtle parts. The welding effect is strong and durable, the appearance is fine and smooth, the workpiece is not easy to deform, the operation interface is simple and intuitive, the learning threshold is low, and it is quick to get started. It is suitable for efficient use by all kinds of professionals and semi-professionals.

- • Laser power: 200w

- • Welding depth: 0.1~3.3mm

- • Wavelength: 1064nm

- • Spot adjustment range: 0.2~2mm

- • Processed materials: gold, silver, stainless steel, titanium alloy

- Information

- Specification

- Application

| Item | W04-200 |

| Maximum laser power | 200W |

| Laser wavelength | 1064nm |

| Max energy of single pulse | 120J |

| Laser welding depth | 0.1~3.3mm |

| Pulse width | 0.3~20ms |

| Laser welding frequency | 0.5~20Hz |

| Adjustable range of spot size | 0.2~2mm |

| Control system | Industrial microcomputer |

| Machine power consumption | ≤4kw |

| Power requirement | 220V±10%/ 50Hz/ 30A |

| System composition | Host computer, cold water tank |

| Consumables | Xenon lamp, filter, protection lens, argon gas |

| Installation | More than 4 square meters |

| Environment | Clean and dust-free or less dust |

| Temperature | 55℉ (13℃) to 82℉ (28℃) |

| Humidity | 5% to 75% non-condensing |

| Power supply | 220V/ 50/60HZ AC, 30A air switch, stable voltage |

W04-200 laser gold welding machine is designed for hole repair and sand hole welding of gold and silver jewelry. As an important application form in the field of laser material processing, the equipment adopts the principle of heat conduction welding, accurately irradiates the surface of the workpiece through a high-energy laser beam, and gradually penetrates the energy into the material through heat conduction. By accurately controlling the key parameters such as the width of the laser pulse, output energy, peak power and repetition frequency, the melting depth and range can be effectively controlled to form a uniform and stable molten pool structure. With its high precision and high stability, it has been widely used in precious metal jewelry manufacturing and high-quality welding scenarios of micro-precision parts.

Flexible parameter settings: The equipment supports flexible adjustment of multiple parameters, including output energy, pulse width, operating frequency and spot diameter, which can be set within a wide range to meet the diverse welding process requirements. All adjustments are completed through the operating lever in the closed control chamber, with scientific structure, convenient operation, precise response, and greatly improved debugging efficiency.

British original ceramic focusing cavity: Equipped with a British original ceramic focusing cavity, it has excellent high temperature resistance and corrosion resistance, significantly improves the photoelectric conversion efficiency, and extends the service life of core components. The focusing cavity design is durable, with an expected service life of 8 to 10 years. With a long-life xenon lamp, it can achieve more than 8 million stable discharges, reducing replacement frequency and maintenance costs.

Intelligent shading systems: Equipped with an internationally leading intelligent shading system, it automatically senses and adjusts the light intensity when the equipment is running, effectively reducing the stimulation of strong light to the operator's eyes, and improving safety and comfort during the operation process.

Support high-intensity continuous operation: the performance of the whole machine is stable and reliable, adapting to long-term and multi-shift production needs, ensuring efficient output under continuous operation, and no special maintenance is required within the first 10,000 working hours, ensuring production continuity.

User-friendly structural design: The overall structural design fully considers the human-machine interaction experience, conforms to the principles of ergonomics, and has a reasonable layout of the operating platform, which reduces the fatigue caused by long-term work and improves work efficiency and comfort.

The W04-200 vertical jewelry laser spot welder has significant technical advantages and performs outstandingly in terms of operating efficiency and process accuracy. Its welding speed is fast and efficient, which can greatly improve production efficiency. At the same time, it has excellent deep melting welding ability and can achieve deep and precise welding. During the welding process, the equipment shows excellent deformation control ability, the deformation of the workpiece is extremely small, and the heat-affected area is narrow, which effectively ensures the stability of the performance of the material around the welding part.

W04-200 gold jewelry laser welding machine can help you easily weld earrings, pendants, bracelets, bangles, rings, crowns made of a variety of pure gold, 18k white gold, rose gold, platinum, etc. In terms of welding quality, its welding effect is excellent, the welding points are smooth and pure, and there is no pollution residue, which fully meets the strict requirements of high-quality jewelry production. In addition, the equipment operation process is efficient and energy-saving, which conforms to the modern environmental protection concept. While bringing efficiency and convenience to production, it also actively responds to the call for green production. This product is a high-quality equipment choice in the field of jewelry processing that combines efficiency and environmental protection.