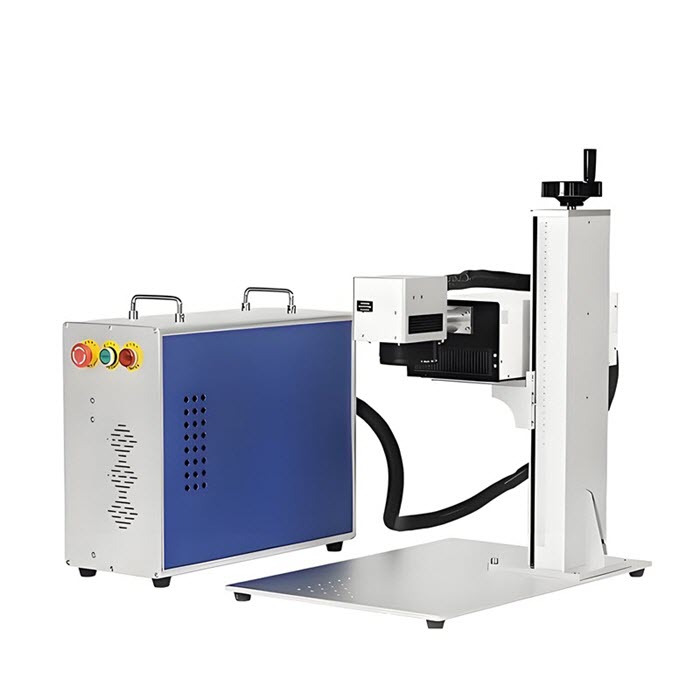

Tabletop Split-type UV Laser Marking System

M11 series split-type UV laser marking system is known for its compact and reasonable structural design and efficient yet stable performance. It is equipped with a high-quality laser generation system and is specially developed for high-difficulty fine marking applications that pursue extreme precision and detail performance. Its split structure facilitates flexible layout and installation in space-constrained environments, improving the adaptability and ease of operation of the equipment. The UV marking system is equipped with a professional water cooling system to effectively ensure the temperature stability of the equipment during long-term continuous operation, avoid performance fluctuations caused by overheating, and ensure processing consistency.

- • Laser power: 3w, 5w, 10w

- • Beam diameter: <1.2mm

- • Marking area: 70*70~300*300mm

- • Minimum line width: 0.01~0.05mm

- • Processed materials: plastic, glass, metal, ceramic, silicon wafer, leather

- Information

- Specification

- Application

| Item | M11-03 | M11-05 | M11-10 |

| Supply voltage | 110v/220v, 50/60Hz | 110v/220v, 50/60Hz | 110v/220v, 50/60Hz |

| Overall power consumption | <1000w | <1000w | <1000w |

| Cooling method | Air/ water cooling | Air/ water cooling | Water cooling |

| Laser output power | 3w | 5w | 10w |

| Laser light source | RFH/ HAN'S/ PulseX | RFH/ HAN'S/ PulseX | RFH / HAN'S/ PulseX |

| Laser wavelength | 355nm | 355nm | 355nm |

| Beam diameter | <1.2mm | <1.2mm | <1.2mm |

| Marking area | 70*70~110*110mm | 70*70~200*200mm | 70*70~300*300mm |

| Minimum line width | 0.01~0.05mm | 0.01~0.05mm | 0.01~0.05mm |

| Minimum character | 0.1mm | 0.1mm | 0.1mm |

| Marking depth | 0.01~0.1mm | 0.01~0.15mm | 0.01~0.2mm |

| Max. marking speed | 7000mm/s | 7000mm/s | 7000mm/s |

| Cable length | 1.5m (cable length and plugs can be customized) | 1.5m (cable length and plugs can be customized) | 1.5m (cable length and plugs can be customized) |

| Working environment | -10℃~40℃ | -10℃~40℃ | -10℃~40℃ |

Lightweight, compact and flexible: M11 series split-type UV laser marking system adopts a miniaturized design with a compact structure and is easy to carry. M11 is highly portable and suitable for flexible transfer between different workplaces, especially for application scenarios with high requirements for space utilization and equipment mobility. The sturdy industrial-grade structure ensures that it can be stably integrated into various production environments, meeting the dual needs of multiple industries for high-precision processing and operational reliability.

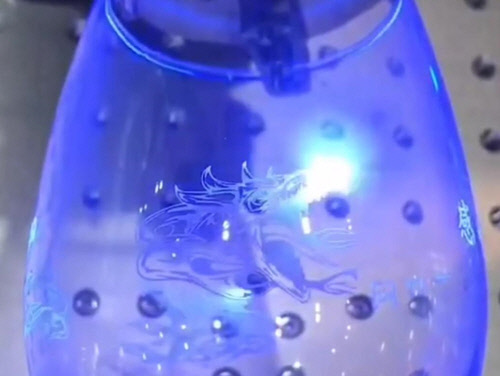

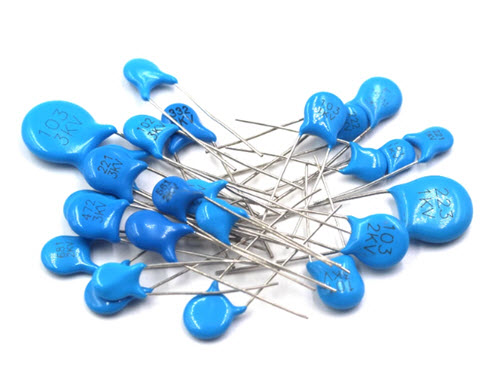

Fine marking, long-lasting and clear marking: equipped with a 355nm UV laser source, it can achieve ultra-fine, high-quality marking without thermal damage by virtue of its excellent material absorption rate and "cold processing" advantages. The UV marking system is particularly suitable for high-end manufacturing fields with strict requirements on precision and surface integrity, such as electronic components, medical devices and precision plastic parts.

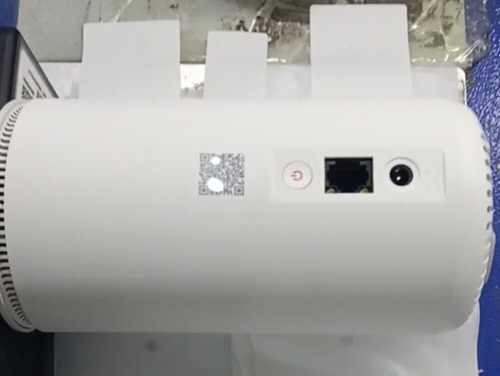

Permanent marking with high damage resistance: the generated mark is clear and sharp, with uniform depth, excellent wear resistance and corrosion resistance, and is not easy to be erased or worn, ensuring that product information can be read for a long time, meeting the needs of key applications such as quality traceability and anti-counterfeiting identification.

Cold laser technology to avoid thermal damage: as a typical "cold laser" device, its short-wavelength ultraviolet light produces almost no thermal effect, effectively avoiding the common problems of burning, melting or deformation in traditional laser processing. M11 is an ideal choice for high-precision processing of heat-sensitive materials (such as plastics, glass, films, etc.).

Green and efficient, no consumables required: the entire marking process does not require the use of inks, solvents or other consumables, which not only reduces operating costs, but also reduces environmental pollution. It is a clean and sustainable processing method that meets the dual pursuit of environmental protection and efficiency in modern manufacturing.

Intelligent water cooling system to ensure stable operation: equipped with a high-performance water cooling module, the UV laser marking system can accurately control the operating temperature of the equipment, ensure stability and safety under long-term continuous operation, extend the service life of core components, reduce the risk of downtime caused by overheating, and improve overall production efficiency.

High-speed and high-precision galvanometer system, accurate positioning: built-in high-quality scanning galvanometer, with excellent linearity and repeated positioning accuracy, fast response speed, minimal drift, support high-speed engraving and accurate restoration of complex graphics, significantly improve processing consistency and finished product yield.

M11 series UV laser marking system provides three power configurations: 3W, 5W and 10W. It can flexibly adapt to the fine marking needs of various materials, such as plastics, glass, leather, ceramics, etc., and is competent for application scenarios with strict requirements on mark clarity and durability. It is widely used in high-precision processing fields such as 3C electronics, food packaging, cable marking, LED lighting components, leather decoration, and pharmaceutical packaging. It is an ideal solution for achieving high-quality marking. With excellent focusing ability and stable output performance, it can easily cope with the fine engraving of complex graphics and tiny text, meeting the high standards of modern industry for accurate identification and durable marking.