Plastic Laser Marking

2025-10-14In modern manufacturing, plastics, as a fundamental raw material, are widely used in the production of a wide range of everyday products. From household appliances to personal electronic devices, we can almost always see clear production information, specifications, models, or decorative patterns on the plastic products. Today, these delicate markings increasingly rely on an advanced technology: laser marking. With continuous technological innovation, laser marking machine has gradually become a vital tool in the field of industrial identification, showing great potential in the plastics processing industry in particular. This article will analyze the application of laser marking machines on rigid plastics, covering key issues such as operating principles, advantages, applicable materials, color control, and equipment selection.

II. What Are the Significant Advantages of Laser Plastic Marking Over Traditional Engraving Methods?

I. How Does a Laser Marking Machine Work to Create Delicate Text and Images on Hard Plastics?

Laser marking is not simply "engraving," but rather a high-energy physical or chemical process. The core principle of plastic laser marking is to use a high-energy-density laser beam focused on the plastic surface to achieve a permanent mark through the following methods:

✅ Thermal effect (carbonization/foaming): The laser beam instantly heats the plastic surface, causing it to partially carbonize and turn black (dark marking) or expand the gas inside the plastic material to form tiny bubbles, resulting in a lighter color (foaming effect). Fiber laser marking primarily relies on this principle.

✅ Photochemical reaction (cold processing): The extremely high energy of UV laser photons can directly break the plastic's molecular chains, triggering a photochemical reaction on the surface, changing its color (such as whitening) with virtually no heat generation, thus preventing burning. This process is called "cold processing." UV laser marking primarily relies on this principle.

✅ Material removal (etching): High-power lasers can directly vaporize portions of the plastic material, creating recessed indentations. This is suitable for markings requiring a noticeable tactile feel. By precisely controlling the power, frequency, scanning speed and path of the laser, clear and permanent marks such as text, patterns, barcodes or QR codes can be formed on the plastic surface.

II. What Are the Significant Advantages of Laser Plastic Marking Over Traditional Engraving Methods?

Compared to traditional inkjet coding, screen printing, or mechanical scribing, laser marking on plastic materials offers unparalleled advantages:

✅ Permanence and High Durability: Laser marking is a physical or chemical change in the plastic surface. It will not fade or peel due to friction, solvents, high temperatures, or UV exposure, ensuring the lifelong effectiveness of the mark.

✅ Non-contact, Wear-Free: The laser beam does not physically contact the material, eliminating tool wear and material deformation, making it particularly suitable for delicate or delicate plastic parts. Laser marking machines do not exert mechanical pressure on the plastic surface, avoiding the damage that can occur with traditional engraving methods, thereby improving product quality and precision.

✅ High Precision and Resolution: Laser marking technology enables micron-level marking on hard plastics, making it easy to create complex patterns, microscopic QR codes, and other markings that are difficult to achieve with traditional methods.

✅ Environmentally friendly and pollution-free: Compared to traditional inkjet coding, screen printing, or mechanical scribing technologies, laser marking requires no inks, solvents, or chemicals, emits no VOCs, and complies with green manufacturing requirements. Furthermore, laser marking produces minimal noise and vibration, making it more environmentally friendly and energy-efficient.

✅ Highly automated and integrated: Laser marking machines can quickly and accurately complete marking tasks, eliminating the cumbersome processes associated with traditional plastic engraving methods and improving production efficiency. Furthermore, laser marking can be easily integrated into production lines, enabling fully automated, high-speed marking and significantly improving production efficiency.

✅ Highly flexible: Through software control, laser plastic marking allows for the ability to change marking content at any time, supporting personalized and variable data marking (such as serial and batch numbers). Furthermore, laser marking machines can be applied to a wide range of plastic materials, enabling efficient and high-quality marking of both large and small plastic parts.

III. What Types of Plastics Can Be Personalized with a Laser Marker?

Plastic is a high-molecular polymer that is lightweight, durable, and highly malleable. Plastic products permeate every aspect of our daily lives. There are many types of plastic, including polyethylene (PE), polypropylene (PP), polystyrene (PS), polyvinyl chloride (PVC), polyamide (PA, commonly known as nylon), and polycarbonate (PC). Most rigid plastics are suitable for laser marking, but the marking effect varies depending on the material composition. The following are common types of plastics suitable for laser marking:

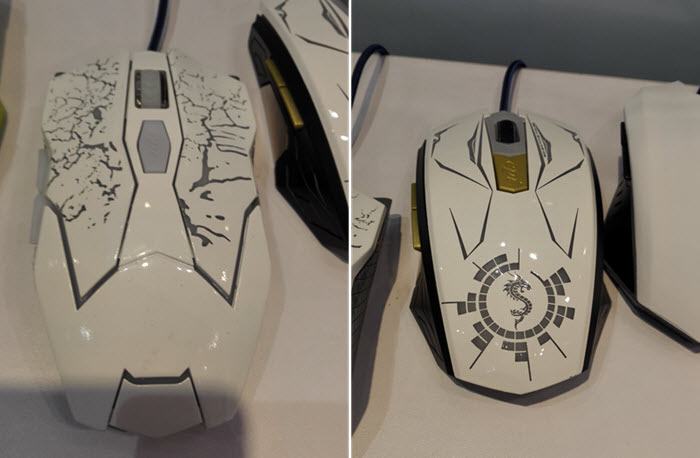

✅ ABS: Widely used in electrical housings and automotive parts, it laser marks well, often resulting in a black or dark gray mark.

✅ PC: Commonly used in electronic devices, eyeglass lenses, and protective covers, laser marking can produce high-contrast marks on these surfaces.

✅ PP and PE: Commonly used in packaging and containers, laser marking parameters must be adjusted to ensure a clear mark.

✅ PVC: Used for pipes and wire insulation. When laser marking PVC, be mindful of chlorine gas release, and a ventilation system is recommended.

✅ PS: Used for disposable tableware, packaging, and other applications, PS plastic is very easy to laser mark.

✅ Engineering plastics such as POM, PA, and PPS: These materials can all achieve high-quality laser marking.

Note: Plastics containing halogenated flame retardants or special additives may affect marking quality, so testing is recommended.

IV. Which Plastics Require Special Attention During Laser Marking?

Although laser marking technology is suitable for most rigid plastics, some plastics exhibit poor laser marking performance due to their physical or chemical properties. These performance issues include low contrast, blurred markings, easy burning, bubble formation, and even the release of harmful gases. The following are some plastics that exhibit poor laser marking performance or require special attention:

1. Purely transparent plastics (such as transparent PC, transparent PMMA/acrylic, and transparent PS)

Problem: The laser beam penetrates the material directly, making it difficult to effectively react with the surface, resulting in extremely faint, almost invisible markings.

✅ Solution:

- Use a UV laser marker (355nm) to create a white or light-colored mark on the surface of transparent materials through a photochemical reaction.

- Adding a laser-sensitive additive to specialized plastics can significantly improve marking contrast.

- Use backside marking (marking on an opaque substrate, visible through a transparent layer).

2. PP (polypropylene) and PE (polyethylene) without laser sensitizers

Problem: PP and PE are crystalline polymers with stable chemical structures. They react weakly to 1064nm fiber lasers, making it difficult to create clear, high-contrast marks. Marks may appear whitish and unclear, or may exhibit slight melting deformation.

✅ Solution:

- Use a high-power fiber laser and optimize parameters (low speed, multiple scans).

- Switch to a CO2 laser marker (10.6μm wavelength), which offers better etching results on PP/PE surfaces.

- Choose specialized PP/PE materials with added laser marking additives.

3. Plastics containing halogen flame retardants (such as flame-retardant ABS and flame-retardant PC)

Problem: Flame retardants containing halogens such as chlorine (Cl) and bromine (Br) decompose under the high temperatures of the laser, releasing toxic and corrosive gases (such as HCl and HBr). These gases pose a health risk to operators and can corrode the laser lens and internal components of the equipment.

✅ Solution:

- Strong ventilation and exhaust gas treatment systems (such as exhaust and activated carbon filtration) are required.

- Avoid using these materials for laser marking, or use halogen-free flame-retardant materials instead.

- Using UV lasers can reduce heat input and minimize harmful gas emissions.

4. Soft/elastic plastics (such as TPE, TPR, silicone)

Problem: The material is soft and easily melts, deforms, and produces burrs after laser heating, making it difficult to create a clean-cut mark.

✅ Solution:

- Use a low-power, high-speed UV laser to achieve "cold processing."

- Optimize the focal length and scanning path to avoid overheating.

5. Black, highly filled plastics (such as carbon black-filled plastics)

Problem: The material itself is a deep black, and the color change after laser marking is subtle, resulting in extremely low contrast and difficult to identify.

✅ Solution:

- Use a foaming marking method to cause the material to expand and whiten in certain areas, creating a "white mark."

- Using a UV laser may cause slight color changes. - Consider changing the material color or using alternative marking methods (such as inkjet coding).

6. PVC (Polyvinyl Chloride)

Problem: While PVC can be marked, because it contains chlorine, the high temperature of the laser will release hydrogen chloride (HCl) gas, which is highly corrosive and toxic, and harmful to equipment and personnel.

✅ Solution:

- Laser marking is not recommended.

- If laser marking is necessary, an efficient ventilation and gas neutralization system must be installed, and the equipment must be regularly maintained.

V. What Factors Influence the Color of Plastic Markings Produced by Laser Marking Machines?

There are many different types of plastics, including common ones like ABS, PP, PC, and PE, as well as a variety of composite materials. Furthermore, plastic products can be given a wide variety of colors during the production process to meet the aesthetic requirements of different products. When using laser marking, the final mark color is not determined by the ink itself but is influenced by a variety of factors, such as the chemical properties and base color of the material itself, the type of laser light source used (such as fiber, UV, or CO₂ laser), and the fine-tuning of equipment parameters.

✅ Plastic Material: Different plastics react differently to lasers due to their chemical structure. For example, light-colored ABS easily marks black, while transparent PC can be marked white.

✅ Laser Wavelength: 1064nm fiber laser marking is prone to carbonization, resulting in a black or gray mark. 355nm UV laser marking triggers a photochemical reaction, often resulting in a white or light-colored mark.

✅ Laser Parameter Settings: Power, speed, frequency, and number of scans directly affect the color depth and contrast of the mark. Low power and slow speed may cause foaming and a white appearance, while high power and fast speed may cause carbonization and a black appearance.

✅ Additives and Masterbatch: Pigments, flame retardants, fillers, and other additives added to plastics can significantly alter the laser reaction and affect the final mark color.

✅ Marking Methods: Laser marking on plastics is primarily achieved through three mechanisms: carbonization, which creates a dark mark; foaming, which produces a light mark; and photochemical discoloration, which causes the surface of the material to appear white or a lighter hue.

VI. Fiber Laser VS UV Laser: Which is More Suitable for Marking Plastic Products?

In the field of plastic laser marking, fiber laser marking machines and UV laser marking machines are two mainstream technologies, each with its own advantages and suitable for different application scenarios.

Fiber laser marking machines primarily work based on the principle of thermal effects, using a laser beam to carbonize or foam the plastic surface, resulting in a dark mark (such as black, gray, or yellow). They offer high marking speed and efficiency, with relatively low equipment and maintenance costs, making them widely used in high-volume industrial production. Although the mark may have a slight uneven feel, fiber lasers offer a stable, clear, and cost-effective solution for common marking needs on most rigid plastics (such as ABS, PC, and PP), such as product model numbers, barcodes, and production dates. They are the preferred choice for industrial marking. Fiber laser marking machines are ideal for marking most common rigid engineering plastics, high-volume production where speed and cost are critical, applications requiring dark (black/gray) or foamed (white) marking, and traceability and identification for industrial parts, electronic components, and daily necessities.

In contrast, UV laser marking machines utilize a "cold processing" method, using high-energy UV photons to trigger a photochemical reaction on the material's surface, achieving subtle color changes (usually to white or light colors) with virtually no heat generation, thus avoiding burning or deformation. This process achieves extremely high marking accuracy, down to the micron level, and the resulting surface is smooth and imperceptible, creating a high-end visual effect. It is particularly suitable for applications requiring exceptional aesthetics and precision, such as consumer electronics housings, medical devices, and high-end packaging. However, UV laser marking machines are typically two to three times more expensive than fiber lasers, with higher maintenance costs and relatively slow marking speeds. Therefore, despite offering the best marking results, they are primarily used for products with stringent quality requirements and high added value.

In summary, fiber laser marking machines, with their cost-effectiveness and high efficiency, have become the mainstream choice in the plastics marking market; while UV laser marking machines hold an irreplaceable position in the high-end, fine-grained marking market. UV laser marking machines are particularly suitable for marking plastics that require heat sensitivity, high precision, and high aesthetics, such as transparent, white, or light-colored plastics; applications requiring white/light-colored markings; products with high surface quality requirements and a non-concave/convex appearance; and fine, miniaturized marking needs.

VII. How to Choose the Right Plastic Laser Marking Machine?

Choosing the right plastic laser marking machine requires comprehensive consideration of multiple factors, including material properties, desired marking results, production efficiency, and budget. We've shared some key points to help you make a more informed decision:

✅ Material Type: Identify the type of plastic you'll be marking and, if necessary, provide samples for testing. Decide whether it's a common engineering plastic like ABS, PC, or POM, or a transparent plastic, soft TPE, or a material with special additives.

✅ Marking Requirements: Do you need high precision? Do you need a tactile feel? Do you have any special color requirements?

✅ Production Efficiency: The average daily number of marks and cycle time will determine the required laser power and marking speed.

✅ Budget: Choose a fiber or UV laser marking machine based on the return on investment.

✅ Integration Requirements: Do you need to integrate with automated production lines? Choose a model that supports interfaces like PLCs and barcode scanners.

✅ After-Sales Service: Choose a supplier with proven technology and excellent service.

Recommendation: When choosing a laser marking machine for marking plastic parts or products, we recommend clarifying your needs, providing sample tests, and then comparing the results with the quote before selecting the optimal model. Before mass production, it's essential to conduct marking tests using actual material samples. Plastic formulations vary significantly between manufacturers and batches, directly impacting marking results. Testing can help determine optimal parameter settings and feasibility, avoiding problems after production.

Plastic Laser marker provides an efficient, permanent, and environmentally friendly marking solution for plastic products. Understanding its operating principles, material compatibility, and equipment differences will help companies make informed choices based on their specific needs. Whether pursuing cost-effective fiber lasers or ultraviolet lasers for ultimate quality, choosing the right model will significantly enhance product added value and production efficiency.