Laser Marking Aluminum

2025-10-16In modern industrial manufacturing and the field of personalized customization, laser marking technology is replacing traditional marking methods at an unprecedented rate, demonstrating its exceptional advantages particularly in aluminum alloy applications. Whether it's precision electronic components, aerospace parts, or everyday consumer goods, laser marking can create permanent, clear, and aesthetically pleasing marks on aluminum surfaces. This article will delve into how laser marking can achieve fine engraving on aluminum alloys, analyzing its technical advantages, applicable materials, markable content, and selection recommendations.

I. How Does a Laser Marking Machine Engrave Aluminum, Such as Anodized Aluminum?

Laser marking is not "engraving" but "modification." It utilizes a high-energy-density laser beam, precisely focused on the aluminum surface. This heat-induced physical or chemical change in the material creates a permanent mark.

For surface-treated aluminum alloys like anodized aluminum, laser marking primarily removes or changes the color of the oxide layer. The anodized layer is typically porous. Laser irradiation causes localized heat to carbonize or alter its structure, resulting in a dark mark (such as black or dark gray). This method eliminates the need for inks or chemicals; simply by controlling the laser's power, frequency, and scanning speed, high-contrast text, patterns, or QR codes can be "drawn" on the oxide layer.

For unanodized pure aluminum or common aluminum alloys, laser marking may result from micro-ablation or surface oxidation, often resulting in a light gray or silvery-white mark.

II. What Are the Advantages of Laser Aluminum Marking Over Traditional Marking Methods?

Compared to traditional methods such as screen printing, chemical etching, and mechanical scribing, laser marking offers significant advantages for aluminum alloys:

▪ Non-contact processing: Laser marking requires no physical contact with the material surface, eliminating tool wear and material deformation. It is particularly suitable for thin-walled or precision components.

▪ Permanent marking: The mark blends seamlessly with the material, resisting wear, corrosion, and high temperatures, and is difficult to erase or tamper with.

▪ High precision and resolution: It enables micron-level engraving, making it suitable for micro components and complex patterns.

▪ Environmentally friendly and clean: It requires no inks, solvents, or chemicals, and produces no waste gas or wastewater, complying with green manufacturing standards.

▪ Efficient automation: It is easily integrated into production lines, enabling high-speed, continuous, and batch marking, improving production efficiency.

▪ Flexibility: Marking content can be modified at any time, supporting customization and the printing of dynamic data (such as serial numbers and dates).

III. What Types of Aluminum Can Be Marked with a Laser Marker?

Laser markers can mark most types of aluminum, but the marking quality (such as color, contrast, and clarity) varies depending on the alloy composition, surface condition, and heat treatment process. The following are common types of aluminum that can be marked and their characteristics:

✅ Aluminum Alloys (Most Common)

Aluminum alloys are the most widely used type of aluminum for laser marking. Due to their excellent workability and mechanical properties, they are widely used in industrial, electronic, and automotive applications.

▪ 1000 Series: Industrial pure aluminum, such as 1060 and 1070, contains ≥99% aluminum. While their surface easily oxidizes, they can be marked, but are highly reflective. Anodizing is recommended before marking.

▪ 5000 Series: Magnesium alloys, such as 5052 and 5083, offer excellent corrosion resistance. They are suitable for use in ships, pressure vessels, and other applications, and offer excellent laser marking results.

▪ 6000 Series: Magnesium-silicon alloys, such as 6061 and 6063, are the most widely used. Used in architectural profiles, electronic product housings, and mechanical components. After anodizing, fiber lasers can produce high-contrast black marks.

▪ 7000 series aluminum alloys, such as 7075 zinc alloy, offer high strength and are used in aerospace and high-end sports equipment. They can be laser marked, but the impact of material hardness on marking parameters should be considered.

Summary: All aluminum alloys can be laser marked. Common engineering aluminum alloys such as 6061 and 6063 are ideal for laser marking because they are often used in anodizing processes.

✅ Industrial Pure Aluminum

Pure aluminum grades such as 1A85, 1070, and 1060 are soft and highly reflective, making direct marking less effective (light color and glare). Anodizing is recommended to form an oxide film before marking, resulting in a clear black mark. Green or UV lasers can also be used to increase absorption and reduce reflection.

✅ Anodized Aluminum

This is the most suitable aluminum material for laser marking. Its surface is coated with a dense aluminum oxide film, typically silver, champagne, or black. Fiber lasers can produce a deep black mark on this oxide layer, offering exceptionally high contrast and resistance to wear and corrosion. It is widely used in applications such as mobile phone cases, laptop computers, and nameplates.

✅ Sandblasted or Brushed Aluminum

This type of aluminum undergoes a physical treatment to create a uniform matte or textured finish. The resulting background is uniform, minimizing distracting reflections, allowing for clear laser marking and a high-end visual effect. It is commonly used in decorative components and consumer electronics.

✅ Coated Aluminum

Aluminum with paint, electrophoretic coating, PVD coating, and other coatings can be marked with a laser. This selectively removes the top coating, exposing the underlying aluminum, creating a "white" or "reverse" effect. This is ideal for designs requiring two-color contrast, such as button logos and decorative patterns.

✅ Aluminum Sheets, Tubes, and Profiles

Any flat sheet, tube, or profiled material within the laser beam's reach can be marked, such as pipe identification, component numbers, and plate traceability codes.

Precautions

▪ High Reflectivity: Untreated bare aluminum has high reflectivity and may damage equipment. Pretreatment or the use of a short-wavelength laser (green/UV) is recommended.

▪ Material Consistency: Aluminum composition may vary between batches or suppliers, affecting marking consistency. Proofing is recommended.

▪ Heat Effects: High-power lasers may cause deformation in thin-walled aluminum parts, requiring optimized parameters.

IV. What Personalized Content Can Laser Marking Machines Help You Engrave on Aluminum Products?

With its high precision, non-contact, and permanent features, laser marking machines can help you mark a wide variety of personalized content on aluminum products. This not only meets functional needs but also enhances product value and brand recognition. The following are common types of content that can be marked:

✅ Textual information: Brand name, model, specifications, production date, expiration date, serial number, batch number, manufacturing location, technical specifications, safety warnings, certification marks, and personalized text. Examples include engraving a user's name on an aluminum phone case and adding technical specifications and serial numbers to nameplates on industrial equipment.

✅ Graphics and Logos: Corporate logos, icons and symbols, decorative patterns, artistic designs, and customized content. Examples include finely engraving a brand logo on an aluminum laptop case and customizing souvenirs.

✅ Data Matrix and QR codes: Used for product traceability, anti-counterfeiting authentication, and intelligent identification. For example, marking aluminum alloy products with Code 128 and EAN-13 codes is used for product numbering and inventory management. QR codes, Data Matrix, and other two-dimensional codes can be used to store more information, such as website addresses, production data, anti-counterfeiting links, and quality inspection reports.

✅ Barcodes and UID codes: By marking aluminum alloy products with serial numbers and unique identifiers, you can achieve full product lifecycle traceability, prevent counterfeiting, and facilitate after-sales service.

✅ Customized patterns: These engravings, such as commemorative text, signatures, and photos, are widely used on gifts, trophies, and souvenirs. Laser marking can imbue these aluminum alloy products with sentimental value and uniqueness, making them suitable for the gift market.

Laser marking machines can comprehensively cover aluminum products, from basic information to highly personalized content, making them an ideal tool for personalized aluminum branding.

V. What Are the Requirements for Aluminum Surface Treatment for Laser Marking?

Laser marking places high demands on the surface finish of aluminum. Different surface treatments directly affect the clarity, contrast, color, and overall aesthetics of the mark. To achieve ideal and stable marking results, aluminum generally requires proper pretreatment. The following are key surface preparation requirements and recommendations:

✅ Surface Cleanliness Requirements

The aluminum surface must be clean, free of oil, dust, fingerprints, residual polishing paste, or oxides. Oil or dust can absorb or scatter the laser light, resulting in blurred marks, uneven color, spots, or broken lines. Salt and oil from fingerprints can cause localized corrosion or discoloration. It is recommended to wipe the surface with anhydrous alcohol, acetone, or a specialized metal cleaner before marking. Wear gloves during operation to avoid direct hand contact with the marking area. For mass production, automated cleaning processes can be installed.

✅ Anodizing

The aluminum surface is anodized to form a dense film of aluminum oxide (Al₂O₃). Fiber lasers produce deep black or dark gray marks on this oxide layer, creating a sharp contrast against the light-colored base. This uniform oxide layer provides consistent marking and is suitable for high-volume production. The oxide layer itself is wear- and corrosion-resistant, ensuring a longer-lasting mark. This treatment is ideal for industrial applications (such as electronics, nameplates, and automotive parts) and is highly recommended for laser marking.

✅ Surface Roughness and Finish

You need to select the appropriate surface finish based on your marking needs. Excessively rough surfaces will scatter the laser, reducing energy density and affecting mark clarity. Sandblasting can increase laser absorption and improve marking quality, especially for dark markings. High-gloss aluminum alloy surfaces such as mirrored or brushed finishes are suitable for marking delicate logos and QR codes, enhancing visual quality. Matte or sandblasted aluminum alloy surfaces provide a uniform background, reduce glare, and enhance mark clarity.

✅ Avoid Highly Reflective Bare Aluminum Surfaces

Untreated pure aluminum or highly polished bare aluminum has an extremely high reflectivity (over 90%) for 1064nm fiber lasers. This not only results in poor marking (light and unclear color), but can also damage the laser or optical components. It is recommended to first treat these aluminum surfaces with a surface treatment such as anodizing, sandblasting, or brushing to reduce reflectivity. For this type of material, we recommend using a green laser (532nm) or ultraviolet laser (355nm). These wavelengths are more easily absorbed by metals and are suitable for direct marking on bare aluminum.

✅ Coating or Plating Treatment

Some aluminum parts have electrophoretic paint, PVD coating, paint, or powder coating. Laser marking can selectively remove the top coating, exposing the underlying aluminum, creating a "white" or "reverse" effect. This creates a two-color contrast design, often used for buttons, decorative parts, and high-end product logos.

CAUTION: Ensure a strong bond between the coating and the substrate to prevent flaking during marking.

✅ Material Uniformity and Consistency

Before laser marking, ensure that the aluminum's alloy composition, hardness, internal stress, and heat treatment are as uniform as possible. Inconsistencies in the material can result in uneven marking color, streaks, or localized variations in the effect.

Before mass production, please test marking on actual surface-treated workpieces. By adjusting parameters such as laser power, speed, frequency, and number of scans, you can find the optimal process combination to ensure a clear, permanent mark that meets product appearance and functional requirements. Good surface preparation is a prerequisite for high-quality laser marking.

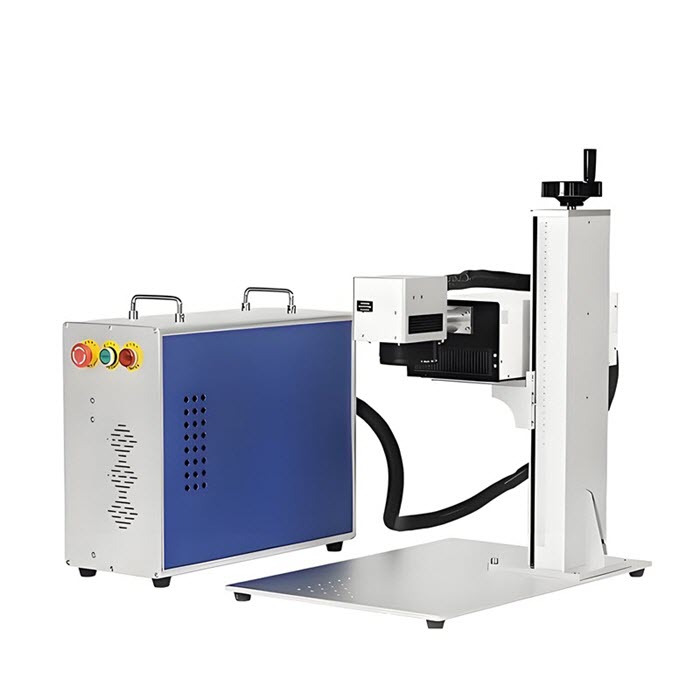

VI. How to Choose the Right Aluminum Alloy Laser Marking Machine?

Selecting the right aluminum alloy laser marking machine requires comprehensive consideration of factors such as material properties, desired marking quality, production efficiency, budget, and long-term maintenance. Here are some selection guidelines to help you make the best decision:

✅ Laser Type:

Fiber laser marking machine: With a wavelength of 1064nm and high metal absorption, it is the mainstream choice for aluminum alloy marking, especially for dark marking on anodized aluminum.

UV laser marking machine: With a wavelength of 355nm and cold working properties, it is suitable for high-precision, heat-free marking of fine parts, such as electronic components.

Green laser marking machine: With a wavelength of 532nm, it is suitable for marking heat-sensitive thin aluminum or colored parts.

✅ Power Selection:

Generally, a 20W-30W fiber laser machine can meet most aluminum alloy marking needs. For highly reflective or thick materials, higher power may be required.

✅ Marking Speed and Accuracy:

Select the scanning mirror speed and focusing lens (e.g., f=160mm or f=254mm) based on your production cycle.

✅ Software and Interfaces:

Supports import from mainstream design software (e.g., CorelDRAW, AutoCAD), and features database connectivity for dynamic marking.

✅ Brand and After-Sales Service:

Select a supplier with mature technology and rapid after-sales response to ensure long-term stable operation.

VII. Precautions for Laser Marking of Aluminum

When laser marking aluminum alloys, the following key points should be noted to ensure marking quality, equipment safety, and production efficiency:

▪ Protective Measures: Lasers are high-energy beams. Protective glasses should be worn during operation, and the equipment should be equipped with a protective shield to prevent laser leakage.

▪ Parameter Adjustment: Before the first marking, parameters (power, speed, and frequency) should be tested to avoid overheating or unclear markings.

▪ Heat Dissipation Management: During continuous marking, pay attention to equipment heat dissipation to prevent overheating and shortening the laser lifespan.

▪ Material Fixing: Ensure the aluminum part is securely clamped to prevent vibration that could cause the marking to shift.

▪ Regular Maintenance: Clean the galvanometer lens and check the laser status to maintain optimal equipment performance.

Laser marking technology adds value and enhances the distinctiveness of aluminum alloy products. It is not only an efficient industrial marking method but also a modern process that blends technology and aesthetics. With the development of intelligent manufacturing, laser marking will play an increasingly important role in the aluminum processing industry, helping companies achieve refined, intelligent, and personalized production goals. Choosing the right aluminum alloy laser marking machine and mastering the correct process will allow you to create endless possibilities on even the smallest aluminum surfaces.