Animal Ear Tag Laser Marking

2025-10-22In daily life, we often see cattle, sheep, and other livestock wearing eye-catching markings on their ears. This marking, called an animal ear tag, also commonly referred to as an animal ear tag, ear number tag, or livestock ear tag, is a tool used to identify and manage livestock (such as cattle, sheep, and pigs). It is typically a small label affixed to the animal's ear, bearing a unique identification number or other information. Currently, a wide variety of content, such as QR codes, text messages, and images, is engraved on animal ear tags using laser marking machines. These markings are corrosion-resistant, abrasion-resistant, and non-fading, ensuring long-term legibility and enabling permanent data preservation. The application of this technology has greatly enhanced the intelligence and traceability of livestock management, providing strong support for animal disease prevention and control and food safety.

I. What Are the Important Uses of Animal Ear Tags?

Ear tags not only provide basic identification but also enable information traceability throughout the entire animal breeding process. Once attached, the animal's relevant information is automatically entered into the management system. Managers can scan the ear tag at any time to access the animal's complete life cycle record, from birth, vaccination, rearing, marketing, slaughter, and even consumption.

☑ Individual Identification: Each ear tag has a unique number that accurately identifies each animal, much like a person's ID number. This helps record and track information such as the animal's birth, rearing, vaccination, and trade.

☑ Disease Prevention and Control: In the event of an animal epidemic (such as foot-and-mouth disease or African swine fever), ear tags can quickly trace the animal's origin and whereabouts, allowing for timely implementation of quarantine, culling, or vaccination measures to prevent the spread of the disease.

☑ Food Safety Traceability: Ear tags are essential for the traceability of livestock products, including meat, throughout the entire chain from farm to table. Consumers can use the traceability system to verify the source of their purchased meat, ensuring food safety. ☑ Scientific Management: Helps farms or animal husbandry departments implement refined animal management, such as recording vaccination, medication, reproduction, and weight changes, thereby improving breeding efficiency.

☑ Compliance with Legal Requirements: In many countries and regions, ear tags for certain livestock are mandatory by law and regulations and a prerequisite for animal quarantine and circulation.

Ear tags are typically made of plastic or metal and come in various colors and sizes to suit different animal species or age groups. Modern ear tags may also incorporate electronic chips (RFID technology) for wireless scanning and automatic data reading, greatly improving management efficiency. In short, animal ear tags are a crucial management tool in modern animal husbandry, playing a vital role in ensuring animal health, food safety, and the standardized development of the industry.

II. What Materials Are Animal Ear Tags Primarily Made of?

Animal ear tags are essential tools for identifying and tracing livestock (such as cattle, sheep, and pigs). They typically require durability, weather resistance, corrosion resistance, UV resistance, and easy marking. Animal ear tags are typically made from different materials depending on their intended use, cost, durability, and technology type (e.g., conventional ear tags or electronic ear tags). The main materials include the following:

1. Plastic (polymer)

This is the most common type of material, widely used in traditional ear tags and some electronic ear tag housings. Commonly used materials for plastic animal ear tags include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and ABS engineering plastics. These plastic animal ear tags have the following advantages:

☑ Lightweight, low-cost, and easy to mass-produce;

☑ Excellent weather resistance, UV resistance, and corrosion resistance, making them suitable for outdoor farming environments;

☑ Laser marking allows for clear inscription of numbers, QR codes, or RFID chip information;

☑ Flexibility reduces damage to the animal's ears. ☑ This type of ear tag is primarily used as a single-use or short-term standard ear tag, as well as as an outer cover for some electronic ear tags.

2. Metal Materials

Animal ear tags made of metal are often used in special environments or when higher durability is required. Common materials for these metal ear tags include aluminum alloy, stainless steel, and copper. They offer the following advantages and disadvantages:

☑ Advantages: Metal ear tags offer significant advantages such as high strength, wear resistance, and tear resistance. They are particularly suitable for large livestock or active animals (such as breeding stock and free-range animals), effectively withstanding external forces and environmental wear. They also have a long service life, are resistant to damage, and can be reused, reducing long-term management costs. Furthermore, metal offers excellent weather resistance, withstanding corrosion from extreme weather conditions (such as high temperatures, severe cold, heavy rain, and strong UV rays) as well as various chemicals, ensuring clear and reliable identification in harsh environments. They are an ideal choice for demanding applications.

☒ Disadvantages: While metal ear tags offer superior performance, they also come with the disadvantages of higher cost and weight. Compared to plastic ear tags, they can place a greater burden on the animal's ears and may cause discomfort if worn for a long time. Therefore, their application is primarily focused on scenarios requiring more reliable identification, such as breeding stock management, scientific research tracking, wildlife monitoring, and individuals requiring long-term or even lifelong identification to ensure the permanence and traceability of information.

3. Electronic Materials (RFID Chip + Packaging Materials)

Animal ear tags made of electronic materials are smart electronic ear tags that enable wireless identification and automatic data reading. Their core components are a built-in micro RFID chip and antenna, typically constructed from silicon-based materials and metal conductors. The chip is encapsulated in a plastic casing (such as epoxy or ABS) to provide waterproofing, shockproofing, and electromagnetic interference protection. These electronic animal ear tags offer the following advantages:

☑ Non-contact reading improves management efficiency;

☑ Large data storage capacity, capable of recording the entire life cycle of an animal;

☑ Strong anti-counterfeiting and tamper-resistant properties.

☑ Animal ear tags made of electronic materials are commonly used in modern farms, national animal traceability systems, and import and export quarantine applications.

4. Composite Materials

Some high-end ear tags utilize a multi-material composite design, such as a "plastic base + metal reinforcement ring" or a "flexible silicone edge + hard label," to achieve both comfort and durability.

Currently, plastic materials (particularly PP, PVC, and ABS) are the mainstream choice for animal ear tags due to their cost-effectiveness, ease of processing, and adaptability. Metal materials, on the other hand, are primarily used in specialized applications. Electronic ear tags, combining a plastic shell with RFID electronic components, represent the future of smart farming. With technological advancements, new materials with improved durability, biocompatibility, and data security are constantly being developed and applied.

III. What Are the Advantages of Using Laser Marking for Animal Ear Tags?

Animal ear tags are well-suited for laser marking technology, and in modern livestock farming, laser marking has become the mainstream and preferred method for ear tag information identification. The following are the advantages of using laser engraving for animal ear tags:

☑ Permanent, indelible marking: Laser marking uses a high-energy laser beam to induce physical or chemical changes on the surface of the material, directly "engraving" the number, QR code, or text. The mark blends seamlessly with the material, offering strong resistance to wear, corrosion, and tampering. It remains clearly readable even in harsh farming environments (such as wind, sun, rain, and frequent friction).

☑ High precision and clarity: Lasers can precisely engrave tiny characters and complex QR codes, ensuring accurate information and facilitating subsequent scanning, traceability, and data management. The high QR code recognition rate supports automated information collection systems. ☑ Compatible with a variety of materials: Plastics commonly used for animal ear tags (such as PP, PVC, and ABS) and some metal materials can all be marked with high quality using various types of lasers (such as fiber lasers, CO₂ lasers, and UV lasers). Laser marking is particularly effective for plastic ear tags, as it does not deform or contaminate the material.

☑ Environmentally friendly and consumable-free: Laser marking requires no inks, solvents, or label paper, making it a clean production method and avoiding the potential for ink bleed and contamination associated with traditional inkjet coding. It also offers lower long-term costs and simplified maintenance.

☑ Supports automation and mass production: Laser marking machines can be integrated with production lines to automatically encode and serialize marking (each ear tag is uniquely numbered), significantly improving production efficiency and meeting the needs of large-scale livestock management.

☑ Compliant with traceability and regulatory requirements: Animal traceability systems in various countries (such as China's livestock and poultry identification system) require that ear tag information be permanent, legible, and traceable. Laser marking fully meets these regulatory standards and is an officially recommended or mandatory technology.

Plastic ear tags for pigs, cattle, and sheep are engraved with unique identification numbers and QR codes using fiber lasers. Laser marking is also commonly used on the outer shells of electronic ear tags to ensure the chip number matches the external marking. Metal ear tags for breeding stock or exported animals are laser-marked for lifelong identification.

Laser marking technology, with its permanence, high precision, durability, and automation compatibility, is ideally suited for animal ear tagging. It not only enhances the practicality and reliability of ear tags but also provides solid technical support for digital management, disease prevention and control, and food safety traceability in the livestock industry. Therefore, laser marking is one of the best options for animal ear tagging.

IV. What Precautions Should Be Taken When Using a Laser to Mark Animal Ear Tags?

When using a laser to engrave animal ear tags, to ensure clear, durable, and efficient marking without damaging the ear tag or the equipment, the following key points should be considered:

1. Select the appropriate laser type based on the material of the animal ear tag.

☑ ABS and PC ear tags: We recommend using a fiber laser marker, which can produce high-contrast, dark (black/gray) markings with clear and stable results.

☑ PP and HDPE ear tags: PP and HDPE are less responsive to fiber lasers. You can try adjusting the parameters or using a CO₂ laser marker (more suitable for organic plastics), but this may result in lower precision.

☑ Light-colored or transparent plastic ear tags: For white marking, use the "foaming" mode on dark substrates, or use a UV laser marker for finer results.

☑ Metal ear tags, such as stainless steel and aluminum alloy ear tags: Fiber lasers have a wavelength of 1064nm. This near-infrared light is efficiently absorbed by most metals (such as stainless steel, aluminum, copper, and titanium), resulting in high marking efficiency. Fiber laser marking machines are the preferred and most popular equipment for metal ear tag marking.

Please ensure that you select the most suitable laser marking machine based on the material of the ear tag and conduct sample tests before purchasing to ensure that the marking effect meets your actual needs.

2. Ensure the surface of the animal ear tag is clean and dry.

Oil, dust, or mold release agent residue on the surface of the animal ear tag can affect laser absorption, resulting in blurred marking, uneven color, or broken lines. Therefore, before using a laser to engrave an animal ear tag, be sure to wipe the surface with anhydrous alcohol or a special cleaner. Avoid direct contact with the marking area to prevent fingerprints.

3. Secure the ear tag to prevent movement.

If the ear tag moves during the marking process, it will result in ghosting, skewed, or incomplete markings. Therefore, before marking, be sure to securely secure the ear tag using a dedicated clamp or jig. During mass production, designing an automated loading and unloading and positioning system can effectively improve marking efficiency and consistency.

4. Optimizing Laser Parameters.

During the laser marking process, it is crucial to properly optimize laser parameters, primarily including power, speed, frequency, scan rate, and focal length. Excessive power can overheat the material, causing plastic melting, blistering, edge burns, and even the production of hazardous fumes. Excessive power, on the other hand, can result in a lighter mark with insufficient contrast, impacting clarity and durability. Therefore, it is recommended to gradually adjust various parameters through proofing and testing to find the optimal combination. For example, using medium power with a higher scan rate and increasing the scan rate can improve contrast and clarity, resulting in high-quality, stable, and durable marking.

5. Controlling Thermal Impact to Prevent Deformation.

Because animal ear tags are often thin-walled plastic parts, concentrated heat during laser marking can easily lead to uneven heating of the material, causing warping, deformation, and internal stress, compromising the structural integrity and wearability of the ear tag. To effectively control thermal effects, pulsed laser processing should be used to avoid continuous heating. Scanning speeds should also be increased to reduce energy input per unit time and minimize heat accumulation. After marking, the ear tag should be allowed to cool naturally at room temperature to avoid secondary stress or material damage caused by rapid cooling, thereby ensuring marking quality and product reliability.

6. Dealing with Marking Fumes and Exhaust Gases.

During the laser marking process for animal ear tags, high temperatures may cause the plastic material to decompose, releasing harmful gases such as chlorine and nitrogen, as well as smoke and dust. These not only pose a health risk to operators but may also corrode internal equipment components and contaminate optical lenses, affecting marking quality. Therefore, a powerful exhaust system must be installed to promptly remove generated smoke and exhaust gases from the work area. It is recommended to also install an activated carbon filter or air purification device to effectively absorb toxic substances and achieve environmentally friendly emissions. Furthermore, the focusing lens and galvanometer lenses should be cleaned regularly to prevent residual contaminants from adhering to ensure a clear optical path and stable and reliable marking results.

7. Ensure legibility of label content.

To ensure legibility of laser-marked ear tags, choose simple, highly recognizable fonts, such as standard fonts like Arial, OCR-A, or OCR-B. Avoid decorative fonts. Ensure the font size is not too small, with a recommended minimum size of at least 1mm, to ensure legibility at both long and short distances. For QR codes or barcodes, ensure the encoding information is accurate. After marking, each tag should be verified with a scanner to confirm readability and data accuracy. Furthermore, the marking position of all ear tags should be uniform and standardized to avoid random marking. This will facilitate rapid identification, data collection, and batch management, improving overall traceability efficiency.

8. Consider the environment and durability.

Because animal ear tags are exposed to the outdoors for extended periods of time, subject to sun, rain, dust, and friction from the animals themselves, laser markings must exhibit excellent weather resistance, resist UV aging, abrasion, and fade. To ensure durable and reliable marking, it is recommended to use inherently weather-resistant plastic materials, such as polycarbonate (PC) or ABS. Laser parameters should be optimized to form a sufficiently deep oxide or modified layer on the material surface, ensuring that the mark is integrated into the material rather than just remaining on the surface. This effectively resists environmental corrosion and mechanical wear, ensuring the mark remains legible throughout the livestock's lifecycle.

9. Safe Operation.

When performing laser marking operations, strictly adhere to safety regulations to ensure the safety of both personnel and equipment. Operators should always wear dedicated laser safety glasses to prevent accidental eye damage from the laser beam or reflections from metal or plastic surfaces. The equipment must be reliably grounded to prevent the risk of static electricity accumulation or leakage, ensuring electrical safety. Furthermore, all operators should receive professional training and be familiar with the correct operating procedures, parameter settings, and emergency response procedures for emergencies to prevent misoperation and ensure a safe, stable, and controllable laser marking process.

10. Prototype Testing and Batch Verification.

Before entering mass production, prototype animal ear tags identical to the actual product must be tested. This thoroughly verifies the laser mark's clarity, contrast, and durability, as well as the scan success rate of the QR code or barcode, to ensure the marking meets user requirements. Once mass production begins, a quality control mechanism should be established, with regular spot checks conducted to check the accuracy, position consistency, and appearance of the marking content. Any parameter drift or equipment anomalies should be promptly identified and corrected to ensure consistent and reliable marking quality across the entire batch.

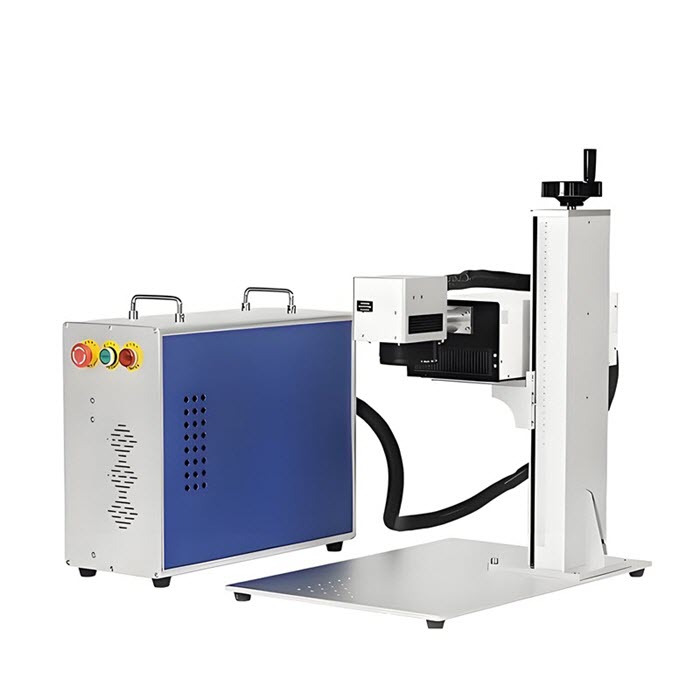

Animal ear tag laser marking machines help you quickly and accurately apply surface coding and marking to various livestock, including cattle, sheep, and pigs. They offer excellent beam quality, resulting in smooth, delicate marking lines. They support automatic numbering, serial numbering, and fine engraving of various text, images, and QR codes, ensuring clear, permanent, and traceable markings. Whether for mass production or customized customization, we can efficiently meet your needs. If you are looking for a high-performance animal ear tag laser marking solution, please feel free to contact us. We will recommend the most suitable model for you based on your specific application to help you with smart livestock management.