All-in-one UV Laser Marking Machine for Plastic

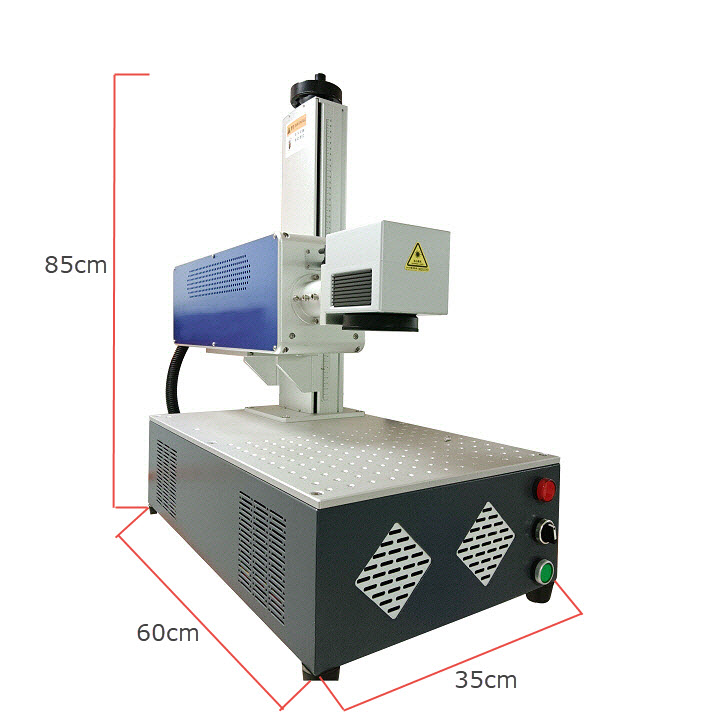

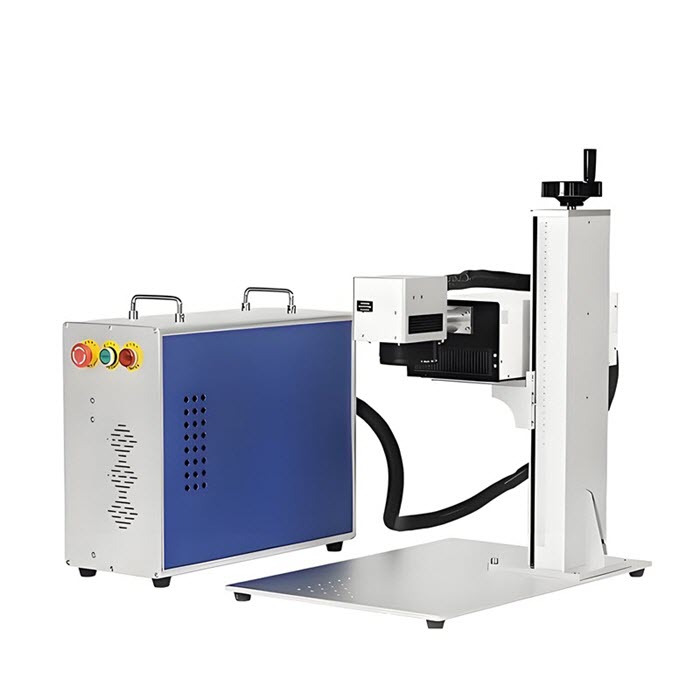

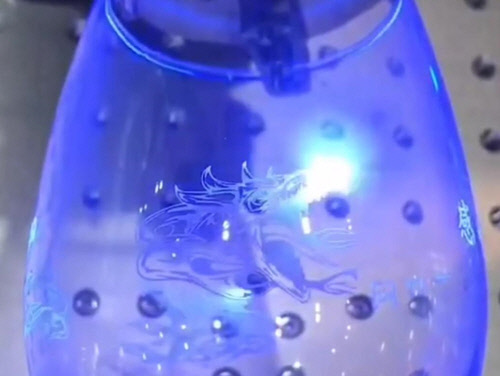

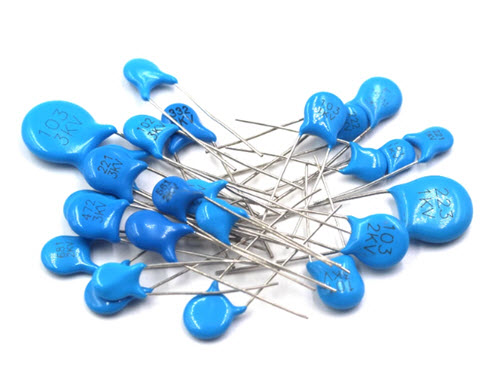

M12 series compact all-in-one UV laser marking machine provides three power configurations: 3w, 5w and 10w. The 3w and 5w machines can be equipped with efficient intelligent air cooling systems, and the 10w is equipped with a well-known brand of water cooling machine to ensure stability during long-term continuous work and meet diverse processing needs. It uses a 355nm short-wavelength UV laser beam with high energy utilization and can achieve fine marking. The overall design effectively suppresses mechanical deformation, while significantly reducing the heat-affected area and reducing damage to the workpiece surface. This feature makes it an ideal choice for ultra-high-precision marking, micro-engraving, and other applications with strict requirements for detail processing and positioning accuracy.

- • Laser power: 3w, 5w, 10w

- • Beam diameter: <1.2mm

- • Marking area: 70*70~300*300mm

- • Minimum line width: 0.01~0.05mm

- • Processed materials: plastic, glass, metal, ceramic, silicon wafer, leather

- Information

- Specification

- Application

| Item | M12-03 | M12-05 | M12-10 |

| Supply voltage | 110v/220v, 50/60Hz | 110v/220v, 50/60Hz | 110v/220v, 50/60Hz |

| Overall power consumption | <1000w | <1000w | <1000w |

| Cooling method | Air/ water cooling | Air/ water cooling | Water cooling |

| Laser output power | 3w | 5w | 10w |

| Laser light source | RFH/ HAN's/ PulseX | RFH/ HAN's/ PulseX | RFH/ HAN's/ PulseX |

| Laser wavelength | 355nm | 355nm | 355nm |

| Beam diameter | <1.2mm | <1.2mm | <1.2mm |

| Marking area | 70*70~110*110mm | 70*70~200*200mm | 70*70~300*300mm |

| Minimum line width | 0.01~0.05mm | 0.01~0.05mm | 0.01~0.05mm |

| Minimum character | 0.1mm | 0.1mm | 0.1mm |

| Marking depth | 0.01~0.1mm | 0.01~0.15mm | 0.01~0.2mm |

| Max. marking speed | 7000mm/s | 7000mm/s | 7000mm/s |

| Cable length | 1.5m (cable length and plugs can be customized) | 1.5m (cable length and plugs can be customized) | 1.5m (cable length and plugs can be customized) |

| Working environment | -10℃~40℃ | -10℃~40℃ | -10℃~40℃ |

M12 all-in-one UV laser marking machine is compact, lightweight and easy to carry, bringing users greater flexibility and convenience. The equipment is easy to install and does not require frequent maintenance, making deployment more efficient. At the same time, it performs well in a variety of application scenarios and operates stably and reliably.

The UV laser source of M12-03 and M12-05 adopts an intelligent air cooling system with automatic speed regulation function, which effectively realizes heat dissipation management, thereby ensuring that the laser is always in an efficient working state, extending the service life while improving the overall operating efficiency.

M12 UV laser marking machine has excellent linear performance and extremely low offset rate, ensuring the accuracy of repeated positioning, so that each processing result remains highly consistent. The structural design focuses on stability and reliability, and is suitable for various applications with strict precision requirements.

M12 series all-in-one UV laser marking equipment is equipped with high-speed scanning technology (Sino-Galvo), has good anti-interference ability, and small zero drift. It is an ideal solution for complex tasks such as high-sensitivity deflection control and two-dimensional precise positioning.

Its working platform is made of high-strength aluminum alloy, which is not only sturdy and durable, but also can maintain excellent stability in harsh environments. The structure is designed to withstand heavy loads and high-intensity operations, enabling it to continuously provide stable performance in industrial scenarios. The fixtures and fixtures support rapid adjustment and replacement, greatly improving the efficiency of workpiece loading and unloading. This flexible configuration significantly enhances the operational adaptability of the equipment, especially for applications that require frequent switching of production tasks and the pursuit of efficient output.

M12 UV laser marking machine is known for its excellent ultra-fine marking capabilities. It can efficiently process a variety of materials, such as glass, plastic, leather and ceramics, and is widely used in the processing needs of different industries. The equipment has diverse functions and stable performance. It has been widely used in many fields such as 3C electronics, food packaging, cable marking, lighting equipment, leather products and pharmaceutical packaging, meeting the stringent requirements for high-quality marking effects.