LED Bulb Laser Marking & Printing Solution

2025-12-03In an era of rapid intelligentization and energy conservation in the lighting industry, LED bulbs, as core end products, not only face higher performance requirements, but the clarity, durability, and aesthetics of their markings are also increasingly becoming crucial components of brand competitiveness. Traditional ink printing methods are prone to fading and peeling under high temperature, high humidity, or long-term use environments, making them unsuitable for modern manufacturing standards. Laser marking technology, with its permanence, environmental friendliness, and high precision, is gradually becoming the mainstream solution for LED bulb marking. Here, we will systematically analyze the value, advantages, technology selection, and application prospects of LED bulb laser marking. If you are looking for LED bulb laser marking solutions or machines, you may find some valuable information here.

I. Why Choose Laser Marking for LED Bulbs?

LED bulbs typically operate in high-temperature, high-voltage environments with a lifespan of 25,000 to 50,000 hours. In this environment, markings on the surface of LED bulbs (such as brand logos, power parameters, certification marks, serial numbers, etc.) must possess extremely strong resistance to aging. Traditional printing methods rely on ink adhering to plastic or glass surfaces, which are easily worn away, blurred, or even completely disappeared during long-term thermal cycling or cleaning, affecting user identification and after-sales traceability.

Laser marking uses a high-energy laser beam to create a physical or chemical reaction with the material, forming a permanent mark on the bulb surface. It requires no ink, produces no pollution, and integrates seamlessly with the substrate. Whether used in consumer-grade household bulbs or industrial-grade high-power lighting modules, laser marking ensures that information remains clearly legible "from manufacturing to disposal," making it the preferred marking process for high-end LED manufacturers.

II. What Are the Core Advantages of Laser Marking on LED Bulbs?

Laser marking on LED bulbs offers many unparalleled advantages, making it a mainstream marking technology in modern lighting manufacturing. Let's take a look at these key advantages:

● Permanent and Durable:

The laser forms an indelible and fade-resistant mark on the bulb surface through physical or chemical changes (such as material vaporization or oxidation). Even in high-temperature, humid, or frequently wiped environments, the marking remains clearly legible.

● High Precision and High Resolution:

The laser spot can be as small as micrometers, accurately engraving various contents, such as clearly printing tiny text (e.g., 0.3mm font), complex QR codes, or fine logos. It is particularly suitable for small, curved, or irregularly shaped workpieces like LED bulbs.

● Environmentally Friendly and Consumable-Free:

No inks, solvents, or other consumables are required, reducing chemical use and waste disposal, complying with RoHS, REACH, and other green manufacturing standards. It consumes only electricity, is simple to maintain (mainly cleaning the optical path and checking the cooling system), and has significantly lower long-term operating costs than traditional inkjet printing.

● Non-contact Processing:

Laser marking requires no physical contact, avoiding indentations, cracks, or deformation to fragile glass or plastic lamp bodies. It is especially safe for ultra-thin or precision structures (such as the metal parts of LED lamp heads). The absence of mechanical pressure prevents damage to fragile LED beads or glass casings.

● High Material Adaptability:

Laser marking machines allow for precise marking on various commonly used materials for LED bulbs, such as glass (e.g., lampshades), engineering plastics (PC, PMMA, PBT, etc.), and metals (aluminum heat sinks, lamp heads). By adjusting the laser wavelength (e.g., ultraviolet, fiber, CO₂ laser), the marking effect on different materials can be optimized.

● Automation-friendly Integration:

Seamlessly integrates with production lines, enabling high-speed online marking and improving overall efficiency. Laser marking machines easily integrate with PLC and MES systems, achieving high-speed online marking (hundreds of characters per second), dynamic content switching (e.g., serial numbers, batch numbers), and multi-station synchronous processing (increasing production capacity). Suitable for various scenarios from small-batch laboratory production to large-scale industrial production.

● Enhancing the Anti-counterfeiting & Traceability Capabilities:

Laser marking machines can print unique identification codes (such as Data Matrix codes) on LED bulbs, enabling full lifecycle tracking. These markings are difficult to copy or tamper with, effectively preventing counterfeit products from entering the market.

III. Comparison of Laser Marking, Pad Printing, and Screen Printing

In the selection of marking processes for precision electronic products such as LED bulbs, laser marking, pad printing, and screen printing each have their own characteristics. However, from a comprehensive performance perspective, laser marking has significant advantages.

● Durability:

Laser marking forms permanent marks by altering the surface structure of the material, exhibiting extremely strong resistance to wear, high temperatures, and chemical corrosion, making it suitable for long-term use or harsh environments. In contrast, pad printing relies on ink adhesion and is prone to peeling off due to friction or aging, resulting in weaker durability. While screen printing is slightly superior to pad printing, its durability still highly depends on ink quality and curing process, placing it at a moderate level overall.

● Precision and Detail:

Laser marking can achieve high-resolution marking at the micron level, suitable for fine text, QR codes, and even miniature patterns. Pad printing is suitable for moderately complex patterns but is limited in expressing fine lines or high-density information. Screen printing, due to limitations in screen tension and ink flow, is prone to burrs at the edges, making it difficult to meet high-precision requirements.

● Environmental Friendliness:

Green and environmentally friendly is another major advantage of laser marking. The entire process requires no ink, solvents, or cleaning agents, and emits no VOCs (volatile organic compounds), aligning with green manufacturing trends. Pad printing and screen printing, on the other hand, require solvent-based inks, generating harmful waste gases and causing wastewater pollution during screen or printing head cleaning, resulting in higher environmental compliance costs.

● Flexibility in Content Change:

Laser marking allows for instant switching of marking content via software adjustments, making it ideal for multi-variety, small-batch, or dynamically encoded (e.g., serial numbers, batch codes) production. Pad printing and screen printing, however, require replacing the printing head/plate or remaking the screen, leading to longer preparation times, higher costs, and difficulty adapting to rapidly changing production needs.

● Adaptability to Curved Surfaces:

Pad printing, due to its flexible printing head, excels at printing on irregular or deeply concave curved surfaces. Laser marking, combined with a rotating axis or 3D galvanometer system, can also efficiently handle curved surfaces such as cylindrical lamp bodies. Screen printing, however, is primarily limited to flat or slightly curved surfaces, resulting in a narrower application range.

● Cost Input:

While laser marking requires a higher initial investment in equipment, it has virtually no consumables, is simple to maintain, highly automated, and has extremely low operating costs. Pad printing requires continuous purchases of ink, printing pads, and solvents, and involves significant manual intervention. Screen printing, on the other hand, has a high plate-making cost ratio for small-batch production, making it less economical.

Therefore, we can see that laser marking is superior in terms of durability, precision, environmental friendliness, flexibility, and long-term economic benefits, making it particularly suitable for LED bulb manufacturing scenarios with high requirements for quality, reliability, and intelligent production.

The above video shows that the NITRATEK fiber laser marking machine, working in conjunction with a rotary axis and a loading/unloading robot, marks content on the curved aluminum alloy surface of the LED bulb bases.

IV. Selecting the Appropriate Laser Marking Machine According to the LED Bulb Materials

In our daily production and life, we see a variety of LED bulb casing materials, including PC (polycarbonate), PP (polypropylene), PBT, glass, and metal heat sinks. Therefore, we need to match different wavelength lasers to different materials:

✅ Engineering plastics such as PC/ABS/PBT: A 3-10W UV laser marking machine (355nm) is recommended. UV lasers are a "cold processing" method, which avoids material carbonization and yellowing, making it particularly suitable for white or light-colored bulbs and ensuring high-contrast white marking effects.

✅ Transparent/Semi-transparent Plastic Cover: You can utilize UV laser marker for internal micro-engraving, achieving translucent marking without damaging the appearance.

✅ Glass Lamp Parts: It can be engraved using a 30W CO₂ laser marking machine (10.6μm) for a matte finish; for finer QR codes, a high-pulse-frequency UV laser marking machine is required.

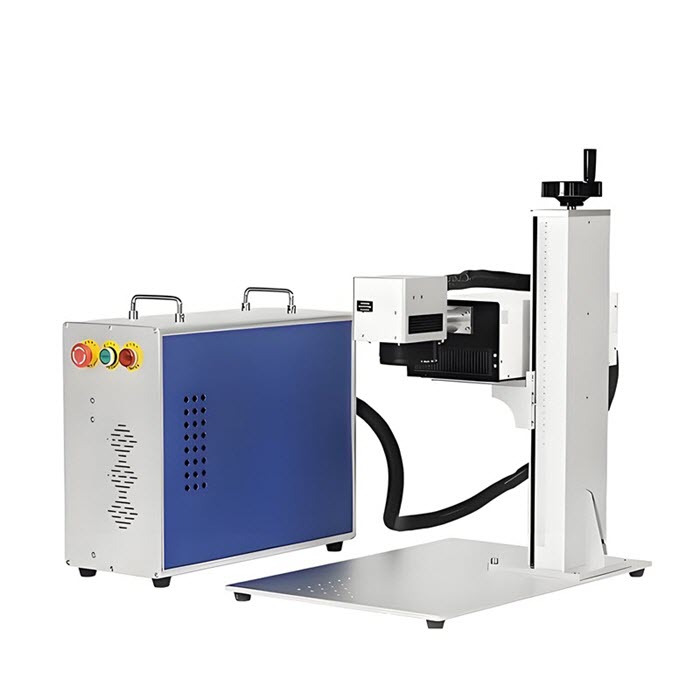

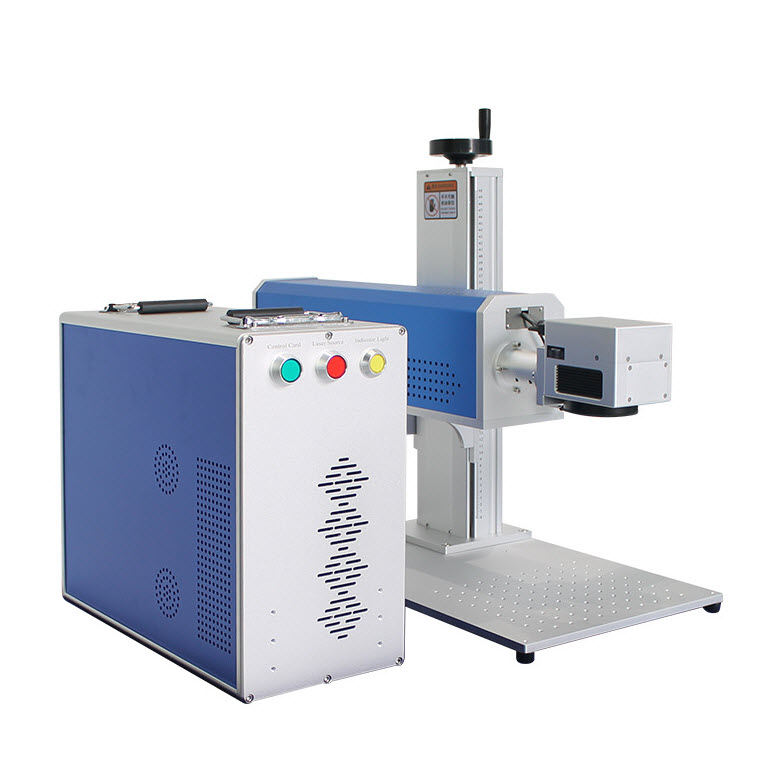

✅ Aluminum Lamp Base or Stainless Steel Cap: You can use a 20-30W fiber laser marking machine (1064nm) for efficient, dark marking with strong adhesion and high-temperature resistance.

Correct selection not only improves the quality of LED bulb laser marking but also extends the lifespan of laser equipment and reduces energy consumption. Even with the same material (such as different grades of PC), differences in additives can significantly affect the actual marking effect. Therefore, we recommend conducting sample tests in advance, or sending your samples directly to us. Our technicians will conduct marking tests on physical samples to obtain the best results. By scientifically matching materials with laser type and parameter settings, we can maximize production efficiency and product reliability while ensuring marking quality.

V. What Types of Content Can Lasers Print on LED Bulbs?

Laser printing can precisely and permanently print various types of content on LED lights (including bulbs, tubes, modules, etc.), widely used in product identification, traceability management, brand promotion, and compliance certification. Laser marking systems support highly flexible content customization:

✅ Basic Product Information:

Brand name, model, power (e.g., "9W"), voltage ("AC 220V"), color temperature ("4000K"), production date or expiration date, etc. This information is usually directly related to user installation and use, and must be clear and durable.

✅ Safety and Certification Marks:

Compliance marks such as CE, RoHS, UL, CCC, etc., as well as energy efficiency rating labels (e.g., EU Energy Efficiency A++) and protection ratings (e.g., IP65). These marks have legal effect and must be clear and tamper-proof—the permanence of laser marking perfectly meets regulatory requirements.

✅ Traceability Information:

Production date, batch number, serial number, QR code, or Data Matrix code, etc., for LED bulbs. Even QR codes as small as 1×1 mm can be recognized by standard barcode scanners.

✅ Personalized Content:

Customized logos, decorative patterns, multilingual instructions, environmental slogans, and other diverse brand marketing content. By controlling laser parameters, different colors can be used to mark metal or plastic LED bulb surfaces, enhancing visual recognition.

✅ Functional Marking:

Dimming indicator arrows, installation direction symbols, replacement prompts, etc. Lasers can accurately engrave simple vector graphics on LED bulb surfaces, suitable for technical guidance markings.

Especially in the era of smart lighting, "one item, one code" has become standard— it means that each bulb has a unique ID. By laser-engraving QR codes, it can be connected to an IoT platform for remote management, fault warnings, and lifecycle tracking.

VI. Flexible Laser Marking Combined with a Two-Dimensional Rotation Axis

LED bulbs are mostly cylindrical or spherical, making it difficult for traditional planar marking equipment to cover curved surfaces. Therefore, modern laser marking systems generally integrate a two-dimensional rotating axis (R-θ axis) to achieve precise 360° engraving without blind spots:

✅ X-Y-Z-θ four-axis linkage: The laser head and rotating fixture move in tandem, automatically adapting to the curvature of the lamp body;

✅ Dynamic focusing: The focal length is adjusted in real time during rotation to ensure consistent marking depth;

✅ High-speed synchronous marking: With a servo motor, full circumference marking of a bulb can be completed within 2–5 seconds;

✅ Multi-station support: Multiple bulbs can be loaded simultaneously, increasing production capacity.

By collaboratively controlling the laser beam path and the LED bulb workpiece posture, the marking system can achieve clear and consistent markings on surfaces of any curvature, similar to printing on a flat surface. This technology is not only suitable for standard A60 and E27 bulbs but can also handle the complex surfaces of irregularly shaped bulbs (such as candle-shaped, bulbous, and corn-shaped bulbs), truly achieving flexible manufacturing where "what you see is what you mark."

The evolution of LED bulbs is inseparable from the upgrading of the underlying manufacturing process. Laser marking machines, with their permanence, high precision, environmental friendliness, and intelligent compatibility, have become an irreversible trend in LED bulb marking. In the future, with the integration of ultrafast lasers, AI visual positioning, and digital twin technologies, LED bulb laser marking machines will further drive the lighting industry towards high quality, traceability, and personalization. If you would like to learn more or are looking for laser marking machines for LED bulbs, please feel free to contact us. We will conduct marking tests based on your provided samples and provide you with satisfactory solutions and reliable equipment.