Textile Fabric Laser Marking

2025-11-11With the deepening of intelligent manufacturing and green production concepts, the processing methods of the traditional textile industry are undergoing profound changes. Laser marking technology for textile fabrics, with its advantages of being non-contact, high-precision, consumable-free, and customizable, has rapidly emerged in the textile field, becoming an ideal alternative to traditional printing, embroidery, washing, and label sewing. It not only achieves permanent product identification but also creates unique visual artistic effects, opening up new paths for brands to enhance added value.

I. How Does a Laser Mark on Textile Fabrics?

Laser marking on textile fabrics utilizes the interaction of a high-energy-density laser beam with the fabric material, forming a permanent mark on the fabric surface through physical or chemical changes. The beam emitted by a laser marking machine (mainly a CO2 laser with a wavelength of approximately 10.6μm) can be effectively absorbed by the organic molecules (such as cellulose, protein, polyester, etc.) in the textile fibers. The absorbed energy is instantly converted into heat energy, causing changes such as ablation, discoloration/charring, foaming, and coating removal in the material, thus forming a unique mark on the textile fabric.

Laser marking on textile fabrics essentially uses light as a tool. Through precise computer control of the scanning path and energy of a high-energy laser beam, it performs "micro-engraving" or "selective color change" on the fabric surface. It does not use ink, is environmentally friendly and efficient, and is particularly suitable for personalized customization, anti-counterfeiting labels, and fine decorations. Its application is increasingly widespread in clothing, home textiles, footwear, and industrial textiles.

II. What Are the Advantages of Laser Marking on Textile Fabrics?

Compared to traditional printing, embroidery, and labeling processes, laser marking on textile fabrics offers a series of significant advantages, making it increasingly popular in the modern textile and apparel industry.

✅ Non-contact marking method

Laser marking uses a non-contact processing method. A laser beam focused in the air acts on the fabric without physical contact. Therefore, no mechanical pressure is generated during processing, effectively avoiding fabric deformation, stretching, or damage that may be caused by traditional embossing or mechanical scratching. It can achieve fine and clear markings without damaging the original structure and feel of the fabric, fully protecting its integrity and quality.

✅ High Precision and High Resolution

Laser marking on textiles boasts high precision and high resolution, perfectly rendering various details. The laser spot can be focused to the micrometer level, enabling the clear reproduction of extremely complex patterns, tiny text, and fine lines. Under proper parameter control, the marking edges are sharp, clear, and free of burrs, resulting in outstanding visual effects.

✅ Permanent Marking with High Durability

Laser marking creates permanent marks with exceptional durability. Its principle involves altering the fabric fibers themselves through laser energy, achieving ablation, carbonization, or discoloration, rather than adding coatings or inks to the surface. Therefore, the marking integrates seamlessly with the material, making it resistant to wear. Even after repeated washing or dry cleaning, the marking will not fade, peel off, or blur, remaining as clear as new. Furthermore, the marking exhibits excellent resistance to most chemical solvents, maintaining stability over long periods in various complex environments, making it suitable for textile marking applications where high durability is required.

✅ Environmentally Friendly and Clean, No Consumables Required

Laser marking is an environmentally friendly and clean processing technology that requires no consumables. The entire process is completely free of ink, dyes, solvents, or adhesives, eliminating chemical pollution and volatile organic compound (VOC) emissions at the source. Simultaneously, since it eliminates traditional processes such as plate making, ink mixing, and screen cleaning, it significantly reduces the generation of industrial waste such as waste liquid and waste plates. As a truly green process, laser marking not only reduces environmental impact but also aligns with the requirements of modern manufacturing for clean production, energy conservation, emission reduction, and sustainable development, making it an ideal environmentally friendly solution for the textile marking industry.

✅ High Efficiency and Speed

Textile fabric laser marking machines are characterized by high efficiency and speed, making them ideal for modern automated production. Complex pattern markings can typically be completed in just a few seconds to tens of seconds, significantly increasing production efficiency compared to traditional embroidery or manual labeling processes. The system employs digital control, directly operated via computer software. Changing the marking content only requires switching the design file, eliminating the need to change molds or screens, greatly reducing changeover and debugging time. Furthermore, laser equipment is easily integrated into existing automated production lines, enabling online, continuous, and precise marking operations, effectively improving overall production efficiency and intelligence.

✅ Flexible Design, Supports Personalized Customization

Laser marking offers exceptional design flexibility, fully supporting personalized and customized production. Whether it's graphics, text, logos, or QR codes, any pattern designed on a computer can be precisely marked on fabric, breaking through the limitations of traditional processes in terms of shape and structure, achieving near-limitless design freedom. Simultaneously, the system supports variable information printing on individual items, easily achieving "one item, one code," personalized names, commemorative dates, and other personalized content, meeting the market demands for small-batch, multi-variety, and customized production, providing brands with differentiated and high-value-added product solutions.

✅ Unique Visual and Tactile Effects

Laser marking not only achieves functional identification but also creates unique visual and tactile effects, enhancing the product's artistic appeal and added value. On natural fibers, lasers can produce subtle charring effects, presenting brown or black tones, giving the fabric a natural, vintage, and handcrafted-like unique texture. By precisely controlling laser energy, slight ablation of localized fibers can also be achieved, forming hollowed-out or semi-transparent patterns, adding depth and decorative appeal. Furthermore, on coated fabrics, lasers can precisely remove the surface coating to reveal the underlying fabric, creating a striking two-tone contrast with strong visual impact, offering more innovative possibilities for designs in clothing, home textiles, and other fields.

✅ Enhancing Product Added Value and Anti-counterfeiting

Laser marking not only improves product functionality but also significantly enhances its added value and anti-counterfeiting capabilities. The fine and permanent markings present a high-tech and high-precision craftsmanship feel, often seen as a symbol of high quality, helping to build a high-end brand image. Simultaneously, laser technology enables "one item, one code." By marking a unique QR code or serial number, consumers can simply scan the code to verify product authenticity, trace production information, and learn about the brand story, greatly enhancing product traceability and credibility. This feature effectively curbs counterfeit and substandard goods, protects brand rights, and also improves the consumer shopping experience and brand loyalty.

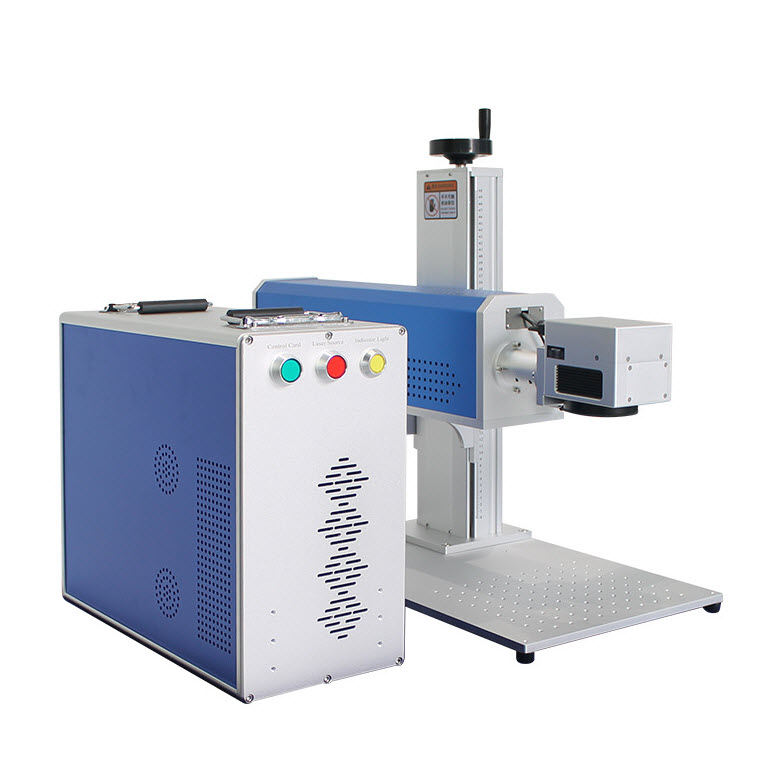

The video above shares a successful application case of laser marking on jeans using a NITRATEK CO2 laser marking machine. CO2 laser marking machines can quickly and accurately mark text, patterns, lines, etc., on a variety of textile fabrics.

III. Which Textile Fabrics Are Suitable for Laser Marking?

Laser marking machines, especially CO2 laser marking machines, are suitable for a wide variety of fabrics. The principle is to use a high-energy laser beam to act on the material surface, forming permanent marks through ablation, color change, or engraving. Laser marking machines are widely applicable to most common natural fiber (cotton, linen, silk, wool), man-made fiber (viscose, modal), and synthetic fiber (polyester, nylon, acrylic) fabrics, as well as their blends. The following are the main types of fabrics suitable for laser marking and their effects:

The application of laser marking machines on textile fabrics combines high precision, permanence, environmental friendliness, high efficiency, and design flexibility. It is not only an advanced processing technology but also an ideal solution for improving product quality, realizing intelligent manufacturing, and meeting personalized consumer needs. Its advantages are particularly evident in high-end apparel, functional apparel, home textiles, footwear, bags, and industrial textiles.

✅ Natural Fiber Fabrics:

● Cotton: Very suitable for laser marking. Laser marking produces light to dark brown marks on cotton fabric, resembling scorch marks, with a clear and permanent effect. It's commonly used for logos or patterns on T-shirts, canvas bags, towels, etc.

● Linen: Similar to cotton, it's easy to mark and produces a clear textured effect, suitable for creating vintage or natural-style decorations.

● Silk: Can be laser-marked, but requires very precise parameter control. Silk is delicate and easily burned through with excessive energy. It's typically used for fine marking on high-end clothing or accessories.

● Wool: Can be marked, but the effect may not be as clear as cotton or linen, sometimes producing scorched edges. Care must be taken to control the energy to avoid excessive damage.

● Denim: Laser marking technology is widely used in the denim processing industry. Denim, as a twill fabric made primarily of cotton, is an ideal material for laser marking. Lasers can accurately simulate the effects of traditional washing, such as whiskering, bleaching, and distressing, with more uniform and controllable results.

This shared video showcases a NITRATEK apparel client using a CO2 laser marking machine to create designs on denim. Through precise laser irradiation, the dye on the denim fabric surface is vaporized, resulting in clear, fade-resistant images, gradients, whiskers, and matte finishes on various denim fabrics. If you are looking for laser marking machines or solutions for textile fabrics, please feel free to contact us.

✅ Man-made/Regenerated Fiber Fabrics:

● Viscose/Rayon: Similar to cotton, these fibers can be effectively marked by lasers, producing clear marks.

● Modal, Lyocell/Tencel: These regenerated cellulose fibers are similar to viscose and are generally suitable for laser marking.

✅ Synthetic Fiber Fabrics:

● Polyester: Widely used in apparel and industrial fabrics. CO2 lasers can produce good marks on polyester, typically in light brown or white (depending on laser parameters and the presence of additives). Note that high temperatures may cause slight melting at the edges.

● Nylon: Also suitable for laser marking, with good results. Commonly used in sportswear, bags, umbrella fabrics, etc.

● Acrylic: Can be laser marked, with effects similar to wool.

● Spandex/Lycra: Usually exists as a blend component, with pure spandex being less common. In blended fabrics, the laser primarily affects the other fiber components.

✅ Blended Fabrics:

● Poly-Cotton Blend: This is one of the most common blended fabrics and is very suitable for laser marking. The effect is between that of polyester and cotton; ideal color and clarity can be obtained by adjusting parameters.

● Other Blends (such as cotton/spandex, polyester/viscose, etc.): As long as they do not contain a large amount of heat-sensitive or reflective metallic fibers, they can generally be laser marked; the effect depends on the main components.

✅ Specially Treated or Composite Fabrics:

● Coated Fabrics: Lasers can precisely remove surface coatings (such as PU and PVC coatings), exposing the underlying fabric and creating unique two-tone or openwork effects. Widely used in footwear, bags, and outdoor products.

● Flocked Fabrics: Lasers can burn away the flocked layer, exposing the base fabric and forming patterns.

● Fabrics with Special Additives: Some fabrics have chemicals added during production that react specifically with lasers, allowing laser marking to produce whiter, brighter, or special color effects.

☒ Fabrics Not Recommended or Require Caution:

● Fabrics Containing Metallic Threads: Such as fabrics with gold or silver threads. Metal reflects the laser, potentially damaging equipment and resulting in unsatisfactory marking effects.

● PVC (Polyvinyl Chloride) Fabrics: Laser treatment releases toxic chlorine gas. Laser treatment of pure PVC or PVC-coated fabrics is strongly discouraged. A strong ventilation system is essential, and it is best to avoid laser treatment altogether.

● Certain Fabrics Containing Halogenated Flame Retardants: These may also release harmful gases under laser treatment.

● Very thin or extremely delicate fabrics: Easily burned through by the laser, requiring extremely low power and high speed, making operation difficult.

In practical applications, it is recommended to first conduct sample testing on scrap materials to determine the optimal laser power, speed, and focal length parameters, ensuring ideal marking results while avoiding damage to the fabric. For safety, a good ventilation and smoke extraction system is essential, especially when handling synthetic fibers.

IV. What Can Lasers Mark on Textile Fabrics?

Laser marking machines, with their high precision and digital control, can mark a wide variety of content on textile fabrics. Almost any graphic or text that can be designed on a computer can be precisely "imprinted" onto the fabric using a laser.

In terms of branding, lasers can clearly and permanently mark company logos, brand names, slogans, and other visual elements on fabrics, not only enhancing product recognition but also strengthening the brand's premium image. Simultaneously, lasers can accurately display product information labels, such as fabric composition (e.g., "100% cotton"), washing and care symbols, size, item number, model number, and country of origin information. This meets regulatory requirements and is convenient for consumers, replacing traditional woven labels or care labels and reducing the feeling of foreign objects.

Anti-counterfeiting and traceability are important application areas for laser marking. By marking unique QR codes, barcodes, or serial numbers, each product can achieve "one item, one code." Consumers can scan the code to verify authenticity, view product origin, brand story, or care instructions, effectively combating counterfeit and substandard products and supporting precision marketing and supply chain management. Furthermore, anti-counterfeiting patterns or microtext can be designed as hidden markings to further enhance security.

At the decorative and design level, lasers can create complex patterns, geometric shapes, artistic illustrations, and even photorealistic grayscale images, widely used in clothing, home textiles, and bags. By controlling laser energy, it is also possible to create hollowed-out, openwork, or contour etching effects on collars, cuffs, or edges, creating delicate lace-like decorations that enhance fashion and breathability. For coated fabrics (such as PU/PVC fabrics), lasers can selectively remove the surface layer, exposing the underlying fabric to create a striking two-tone contrast pattern. On flocked fabrics, lasers can burn away specific areas of the flocking to reveal patterns and enrich visual depth.

Functional Marking: Lasers also possess powerful functional marking capabilities, such as marking cutting lines, sewing alignment points, and size scales on fabrics, improving production accuracy and efficiency. Warning symbols can be marked on safety clothing or protective equipment to ensure safe use. Simultaneously, lasers support highly personalized customization, allowing the addition of names, signatures, commemorative dates, or customer-specific patterns and text to meet the demands of the small-batch, customized market. For specially treated fabrics, lasers can even produce non-burning effects such as foaming and whitening, breaking through the color limitations of traditional marking and expanding the boundaries of creative design.

Laser marking has virtually unlimited applications on textile fabrics, ranging from practical information (composition, size, QR codes) to brand image (logo), artistic decoration (patterns, photos), and personalized customization (name, anniversary). It is particularly widely used in clothing, footwear, home textiles, bags, and industrial textiles.

V. What Precautions Should Be Taken When Using a Laser Marking Machine to Mark Textile Fabrics?

1. Safety Precautions

Safety is paramount when laser marking textiles. A powerful ventilation system must be in place to promptly remove fumes and harmful gases generated by laser ablation (such as chlorine gas that may be produced when processing synthetic fibers or PVC fabrics) to prevent equipment contamination, damage to optical components, or health hazards. Due to the high temperature of the laser and the flammability of the fabric, there is a fire risk. Unattended operation is strictly prohibited. Fire extinguishers should be available in the work area, flame-retardant materials should be used as a substrate, and the marked area should be checked for cooling after marking. Operators must avoid direct contact with the laser beam or its reflected light, ensure the equipment's protective cover is intact and effective, and should only operate the equipment after receiving professional training to ensure personal and equipment safety.

2. Material and Effect Precautions

Before laser marking, a sample test must be conducted based on the fabric material (e.g., cotton, polyester, silk, blends, etc.) to determine the optimal laser power, speed, frequency, and other parameters, ensuring clear markings and avoiding burn-through or melting. Different materials react differently, requiring special attention: fabrics containing PVC, metal fibers, or certain flame retardants are not suitable for laser treatment. The fabric should be flat and fixed during marking. A vacuum adsorption table or clamp is recommended to prevent wrinkles from causing inaccurate focus, blurry markings, or uneven marking depth. Marking colors are usually monochrome; natural fibers are often brown to black, while synthetic fibers may be light brown, white, or gray. The effect is affected by the fabric's base color; dark markings are less visible on dark fabrics, while dark or foamed white markings are more effective on light-colored fabrics.

3. Equipment and Operation Precautions

During laser marking, ensure accurate focusing and adjust the focal length according to the fabric thickness to avoid blurry markings due to energy dispersion. Regularly clean the laser lens, reflector, and galvanometer window to prevent dust and fiber residue from affecting optical path transmission and marking quality. Parameter settings should be finely optimized; avoid blindly using "high power + low speed" to prevent fabric carbonization, perforation, or melting. Use the lowest effective energy while ensuring quality. For synthetic fibers such as polyester and nylon, laser heat may cause edge melting. This can be effectively controlled by adjusting the pulse mode and increasing the marking speed to improve marking accuracy and appearance quality.

Laser marking technology for textile fabrics integrates practicality, visual aesthetics, and environmental friendliness, profoundly transforming textile production models and design boundaries. It not only effectively overcomes the limitations of traditional processes in terms of environmental pollution and production efficiency but also provides strong support for brands to create unique personalities and enhance market competitiveness. With continuous technological advancements, laser marking machines for textile fabrics will show broad prospects in a wider range of fabric types and application fields, accelerating the textile industry towards a new stage of intelligent and sustainable development. If you are looking for textile marking solutions or equipment, please feel free to contact us.