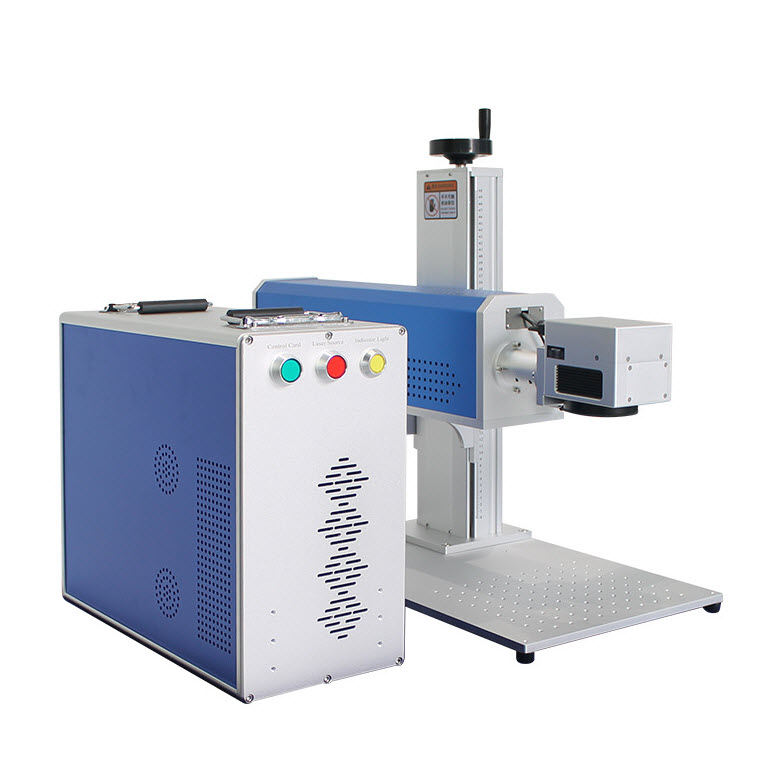

30w 40w 60w Flying CO2 Laser Marking Machine

M09 series flying CO₂ laser marking machine adopts an integrated compact structure, fully optimizing space utilization while having good mobility. Its modern and simple appearance design is not only beautiful, but also helps to create a clean and efficient working environment, especially suitable for production sites with high requirements for site utilization. The equipment is equipped with high-speed non-contact laser technology, which effectively improves processing efficiency, reduces material loss, and helps companies achieve lean production. In addition, the M09 model is equipped with a high-performance workbench lighting system, which significantly enhances the visual clarity during operation, ensures that the marking position is accurate, and greatly improves the safety and stability of operations. This design optimization not only ensures high-quality output, but also provides reliable support for continuous production, fully meeting the dual needs of modern manufacturing for efficiency and precision.

- • Laser power: 30w, 40w, 60w

- • Beam diameter: <1.2mm

- • Minimum line width: 0.01~0.1mm

- • Wavelength: 10.6um

- • Processed materials: wood, acrylic, glass, textiles, leather, plastics etc.

- Information

- Specification

- Application

| Item | M09-30 | M09-40 | M09-60 |

| Supply voltage | 110v/220v, 50/60Hz | 110v/220v, 50/60Hz | 110v/220v, 50/60Hz |

| Overall power consumption | <1000w | <1000w | <1000w |

| Cooling method | Air cooling | Air cooling | Water cooling |

| Laser output power | 30w | 40w | 60w |

| Laser light source | DAVI/ CRD/ HAN's | DAVI/ CRD/ HAN's | DAVI/ CRD/ HAN's |

| Laser wavelength | 10.6um | 10.6um | 10.6um |

| Beam diameter | <1.2mm | <1.2mm | <1.2mm |

| Marking area | 100*100~200*200mm | 100*100~300*300mm | 100*100~500*500mm |

| Minimum line width | 0.01~0.1mm | 0.01~0.1mm | 0.01~0.1mm |

| Minimum character | 0.5mm | 0.5mm | 0.5mm |

| Marking depth | 0.1~0.5mm | 0.1~2mm | 0.1~4mm |

| Max. marking speed | 7000mm/s | 7000mm/s | 7000mm/s |

| Cable length | 1.5m (cable length and plugs can be customized) | 1.5m (cable length and plugs can be customized) | 1.5m (cable length and plugs can be customized) |

| Working environment | -10℃~40℃ | -10℃~40℃ | -10℃~40℃ |

High-precision positioning and efficient marking: M09 series CO₂ flying laser marking machine can integrate advanced CCD (charge coupled device) visual positioning system to ensure excellent processing accuracy and efficient operation process. The system can capture the position information of the workpiece in real time, so as to achieve high-precision marking without fixed fixtures, which greatly improves the level of automation. In addition, it also supports the processing of multiple workpieces at the same time, significantly reducing the processing time of a single workpiece and greatly improving the overall production capacity.

High-speed continuous marking, improve productivity: designed for high-speed continuous production lines, the M09 series flying laser marker can achieve fast and stable operation while ensuring high-quality marking. This equipment is very suitable for assembly line operation environments, helping companies to speed up production and improve output efficiency. Whether it is mass production or customized production, the M09 series can meet the needs and help companies optimize production processes.

Wide material compatibility: M09 series flying CO₂ laser marking system is suitable for fine processing of a variety of non-metallic materials, including but not limited to wood, acrylic, glass, cloth, paper, leather and various types of plastics. Its wide range of applications covers packaging and printing, craft gift making, electronic component identification, textile and clothing and other industries. No matter what material you need to mark, we can provide excellent solutions based on actual application requirements to meet diverse market needs.

Micron-level fine spot ensures clear marking: M09 series machine has micron-level fine focusing capability, the laser spot diameter is less than 1.2mm, and has excellent resolution performance. Whether it is on the surface of materials such as wood, cloth or plastic, it can achieve clear, detailed and lasting marking effects, which is particularly suitable for industrial scenarios with extremely high requirements for precision and details.

Intelligent coding function to reduce manual intervention: the flying CO2 laser marking machine has built-in intelligent data processing function, which supports automatic recognition and printing of various information such as serial number, batch number, date code, barcode and QR code. Through the integrated information management method, it effectively reduces manual operation links, reduces the error rate, and significantly improves the intelligence and automation of the production line.

Convenient operation and strong compatibility: its control system adopts an intuitive LCD touch interface, which is easy to operate and users can quickly get started without long-term training. At the same time, it supports the import of multiple common graphic formats such as PLT, DXF, BMP, etc., with strong compatibility, and can easily connect to various production processes to improve work efficiency.

Energy-saving and efficient, long-term stable operation: the optimized design of the whole machine structure takes into account low energy consumption and high stability, and is suitable for high-intensity continuous working environment. The core laser module has a long life and low maintenance frequency, which not only reduces operating costs, but also provides enterprises with advanced identification solutions that are both economical and reliable, meeting the needs of modern industry for green manufacturing and sustainable development.

The M09 series flying CO2 laser marking machine performs well in non-metallic material processing and is suitable for fine marking of various materials such as wood, leather, acrylic, glass, paper and cardboard, plastic, rubber and various textiles. Its efficient and stable performance makes it widely used in packaging, electronic manufacturing, wood craft processing and other industries. It can accurately complete various tasks such as product information identification, serial number engraving, brand logo printing and decorative pattern production, meeting the multiple needs of industrial production and personalized customization.