Wood Laser Marking

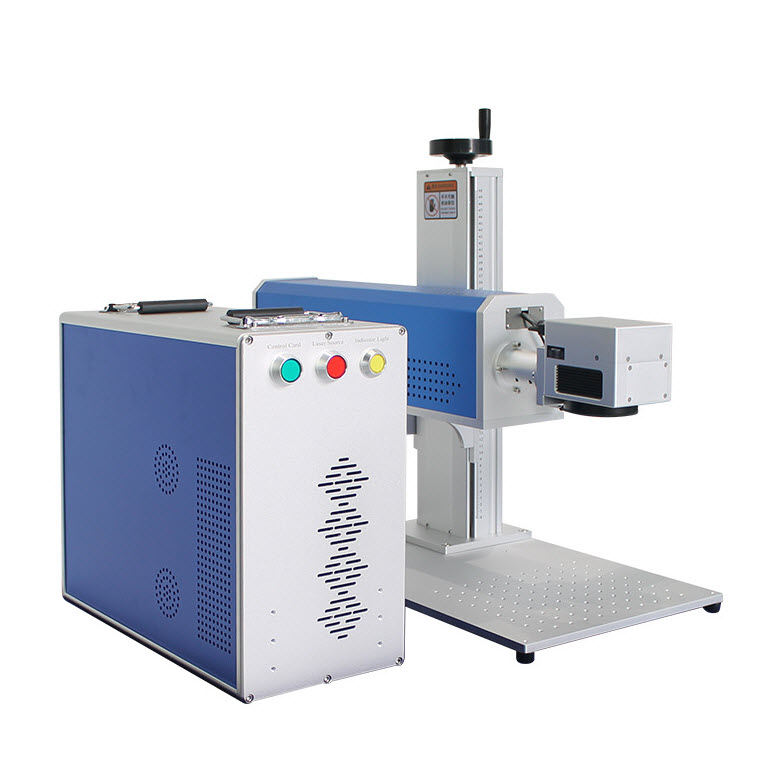

2025-10-28With the growing popularity of modern manufacturing and personalized customization, laser technology is gradually transforming traditional processing methods. Wood laser marking, as a non-contact, high-precision process, has been widely adopted in industries such as crafts, furniture, stationery, packaging, and gifts, making it an ideal choice for permanent marking and artistic engraving on wood surfaces. In this article, we will thoroughly explain the working principles of wood laser marking, optimal equipment selection, applicable wood types, the impact of wood grain, and burn prevention techniques. We will also showcase real customer samples using a NITRATEK CO2 laser marking machine. If you are looking for a wood laser marking system or solution, we hope this article will be helpful.

I. Working Principle of Wood Laser Marking Machines

Wood laser marking is a non-contact processing technology that uses a high-energy-density laser beam to locally heat the wood surface. Its operating principle is as follows: A CO₂ laser emits far-infrared laser light with a wavelength of 10.6μm. A galvanometer system and focusing lens precisely focus the laser beam on the wood surface. The cellulose and lignin in the wood rapidly absorb the laser energy, causing a sharp increase in local temperature and slight ablation or carbonization, resulting in a dark brown or black mark. A computer controls the movement of the laser spot, and the galvanometer deflects the laser beam to achieve high-speed scanning, creating text, patterns, logos, or QR codes line by line. By adjusting the laser power, scanning speed, and frequency, the marking depth can be precisely controlled, achieving a variety of effects from shallow marking to deep engraving and even hollowing. The entire process requires no tools or inks, is clean and environmentally friendly, and achieves processing accuracy down to the micron level.

II. What Are the Advantages of Laser Marking Wood Over Traditional Wood Marking Methods?

Compared to traditional methods like engraving, printing, or labeling, laser marking offers several significant advantages, making it widely used in modern wood processing and marking:

Non-contact processing and no mechanical damage: Laser marking requires no tools or physical contact, avoiding the wood cracking, burrs, and tool wear that can occur with traditional mechanical engraving. It is particularly suitable for processing thin panels, delicate components, or delicate wood.

High precision and exceptional detail: The laser beam can be focused down to the micron level, enabling precise engraving of complex patterns, fine text, QR codes, and even photo-quality grayscale images, achieving a level of detail and clarity unattainable with traditional methods.

Permanent marking and high durability: The laser creates a mark by carbonizing the wood surface, blending it into the material. It is waterproof, oil-resistant, abrasion-resistant, and resistant to fading or erasure, making it far superior to ink printing or adhesive labeling.

Clean and environmentally friendly, no consumables or pollution: The processing requires no inks, solvents, or cutting tools, generating no chemical waste and only a small amount of wood dust (which can be handled by a vacuum system), complying with green production requirements and reducing environmental pollution.

High processing efficiency and high degree of automation: Computer-controlled laser path enables rapid switching between different patterns, supports batch and continuous operation, and is easily integrated into automated production lines, significantly improving production efficiency and reducing labor costs.

Flexible and high design freedom: Marking of various contents can be achieved by simply changing the graphic file in the computer, without changing molds or plates. This makes it ideal for customization, small-batch production, and rapid prototyping.

Multiple effects: By adjusting parameters such as laser power and speed, the same device can perform a variety of processes, including superficial marking, deep engraving, and hollow cutting. This allows for multiple uses and expands the scope of applications.

Increased product added value: Highly precise, beautiful, and permanent laser marking significantly enhances the appearance, quality, and brand image of wooden products, and is widely used in high-end crafts, furniture, and gifts.

In summary, wood laser marking surpasses traditional methods in terms of precision, durability, environmental protection, efficiency and flexibility, and is an important technical means for the modern wood processing industry to achieve high-quality and intelligent production.

III. Which Type of Laser Marker is Best for Marking Wood?

☒ Fiber laser marking machine (wavelength 1064nm):

Primarily used for marking metal materials (such as stainless steel, aluminum, and copper). Its absorption rate on wood is very low, typically producing only very shallow marks on the wood surface. The concentrated energy may even cause the wood to burn or catch fire, preventing ideal marking or engraving results.

☒ UV laser marking machine (wavelength 355nm):

While it can be used on some non-metallic materials, its characteristic is "cold processing," primarily removing material through a photochemical reaction. It is more suitable for high-precision marking on brittle materials (such as glass and ceramics) or materials sensitive to heat. Its marking efficiency on wood is low, its cost is high, and it struggles to achieve deep engraving, making it far less cost-effective than CO₂ lasers.

☑ CO₂ laser marking machine (wavelength 10.6μm):

CO₂ lasers emit a wavelength of 10.6μm, which is in the far-infrared band. The main components of wood, such as cellulose, lignin, and hemicellulose, have a strong absorption capacity for lasers at this wavelength, efficiently converting light energy into heat, achieving rapid carbonization and engraving. CO2 laser marking machines create clear, high-contrast, and dark (typically dark brown or black) permanent marks on wood surfaces, with clean edges and excellent detail. In addition to surface marking, CO2 lasers can also perform deep engraving and even hollowing, meeting diverse processing needs.

For wood marking and engraving, CO2 laser marking machines are the best and most popular choice. Due to their excellent compatibility with wood materials, excellent marking results, and proven technology, they are widely used in crafts, furniture, packaging, and cultural and creative products. When purchasing a CO2 laser, you should select the appropriate power and format based on your specific processing requirements (such as marking depth, speed, and material thickness).

IV. Which Wood Types Are Best Suited for Laser Marking?

Not all wood types yield ideal results when laser marked. Laser marking performance depends primarily on the wood's density, resin content, grain structure, and surface treatment. The following wood types are widely considered the most suitable for laser marking and engraving, producing high-contrast, clear, and aesthetically pleasing marks:

1. Natural Hardwood

Natural hardwood (hardwood) is a preferred material for laser marking due to its moderate to high density, uniform texture, and beautiful grain. Laser carbonization produces deep, high-contrast, and sharp marks, making it widely used in high-end manufacturing and artistic creations.

☑ Walnut has a uniform texture and a warm color. After marking, it develops a deep chocolate color, giving it a luxurious feel. It is often used in crafts, furniture nameplates, and gifts.

☑ Cherry has a smooth surface and fine grain. Its markings range from reddish-brown to dark brown, becoming more mellow and elegant with age.

☑ Oak has a bold, clear grain, and laser engraving can fully highlight its natural texture. It is suitable for decorative panels, wine boxes, and floor markings.

☑ Maple is light in color and hard in texture. After marking, the pattern develops a vivid dark brown, making it suitable for applications such as fine text, graphics, and QR codes.

☑ Teak is rich in natural oils, highly weather-resistant, and produces long-lasting, clear markings. It is often used for outdoor products.

☑ Precious woods such as sandalwood and ebony, with their deep color and dense structure, are laser engraved to enhance their unique texture and collectible value. They are widely used in artwork and high-end jewelry.

2. Uniform Cork

Although some corks are soft, they are also suitable for laser processing if their surfaces are smooth and free of excess resin, particularly for high-volume, low-cost applications.

☑ Birch: With its light color and fine grain, it often comes in the form of multi-layer plywood (birch board). It is a popular material for laser cutting and marking, offering a high cost-effectiveness.

☑ Poplar: Light and soft, it is easy to engrave and is often used for marking models, toys, and packaging linings.

☑ Pine: Pine is relatively common, but contains a high amount of resin. Laser processing may produce smoke or burn marks. It is recommended to pre-clean any resinous areas or use a lower power setting. It is suitable for decorative markings where precision is not a priority.

3. Man-Made Boards

Man-Made boards with surface treatments are widely used in industry. As long as the surface of these boards is wood, they are also suitable for laser marking.

☑ Medium-density fiberboard (MDF): Its surface is extremely flat, free of natural grain, allowing for high-precision, high-contrast engraving. It is widely used in signage, photo frames, display stands, and more.

☑ Plywood: Plywood, especially those with a high-quality veneer surface, allows for high-quality surface marking. Be aware that the multi-layer structure may result in uneven engraving depth.

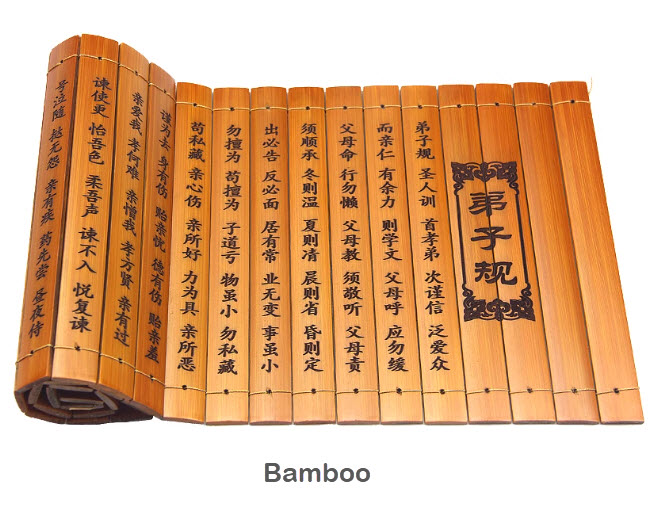

☑ Bamboo: Although not a traditional wood, its fiber structure is similar. Laser marking creates a unique golden or dark brown stripe effect. It is often used for tableware, stationery, and decorative items.

Selection Tips and Considerations

1. Prioritize light-colored, evenly grained woods, such as maple, birch, and cherry. Laser carbonization provides higher contrast and a better visual effect.

2. Avoid woods with high resin content or chlorine treatments, such as untreated pine (which tends to smoke), PVC-coated boards, or flame-retardant wood (which produces toxic gases).

3. The surface should be dry, clean, and free of oil and dirt. Wet or contaminated surfaces can affect laser absorption, resulting in uneven marking.

4. A test sample is recommended. Wood properties may vary between batches and origins. Before processing, adjust parameters such as power and speed to achieve optimal results.

Natural hardwoods such as walnut, cherry, oak, and maple, as well as man-made wood materials such as MDF and birch plywood, are ideal materials for laser marking, fully leveraging the advantages of laser technology in terms of precision, aesthetics, and durability.

V. Does Wood Grain Affect Laser Marking?

Wood grain can significantly affect laser marking. As a natural organic material, wood's grain (i.e., growth rings, vessels, and density differences between early and late wood) is not uniform. This nonuniformity is directly reflected in the final mark quality during laser processing.

Specific effects of wood grain on laser marking:

1. Uneven mark color and contrast

Springwood is typically loose, lighter in color, and has a low density. It absorbs laser light quickly and easily undergoes significant carbonization, resulting in dark marks. Meanwhile, autumnwood is denser and harder, making it more difficult for lasers to penetrate and heat it, resulting in less carbonization and a lighter color. Within the same laser scan line, the mark color will alternate between light and dark depending on the early and late wood. This can cause the overall pattern to appear blurry and inconsistent, affecting both aesthetics and readability (especially for QR codes or small text).

2. Inconsistent engraving depth

Wood density and hardness vary from area to area. Lasers remove material more easily and produce deeper engravings in soft areas (such as earlywood and large-diameter ducts). However, they have difficulty removing material in hard areas (such as latewood and densely fibered areas), resulting in shallower engravings. As a result, laser-engraved patterns can have varying depths and uneven surfaces, which can affect tactility and subsequent processing (such as painting and filling).

3. Reduced Edge Sharpness

In areas with complex textures (such as interlaced grain and near knots), uneven laser energy distribution and heat conduction can cause carbonization boundaries to spread or burrs to appear. Pattern edges become rough and jagged, and fine lines may appear interrupted or thickened.

4. Unique Grain Textures Create Unique Visual Effects

While wood grain poses challenges, its proper use can also create artistic effects. For example, laser engraving on woods with distinct grains, such as oak, can highlight the natural texture, blending the pattern with the wood grain, creating a vintage, natural look. This is often used in decorative paintings and handicrafts.

How to reduce the impact of wood grain on laser marking?

1. Choose wood with a uniform texture: Prefer wood with a fine grain and minimal density variations, such as maple, cherry, MDF, or high-quality plywood.

2. Optimize laser parameters: Appropriately increase laser power and reduce scanning speed to enhance processing capabilities on hard surfaces.

3. Use vector engraving instead of fill scanning to reduce unevenness caused by multiple scans.

4. Pre-treat the wood surface: Ensure the wood is dry (with a moderate moisture content of 8%–12%). Excessive moisture can affect laser absorption. Finely sand the surface to remove burrs and unevenness.

5. Post-processing: After marking, gently wipe the surface with a soft cloth to remove loose carbon and achieve a purer color. Applying wood wax or varnish can protect the mark, provide a uniform surface gloss, and partially conceal color variations.

6. Consider the direction of the wood grain when designing: Try to align text or lines with the wood grain to minimize the sense of disconnection caused by intersecting grain lines.

Wood grain is a key factor affecting the effectiveness of wood laser marking, often resulting in issues such as varying color shades, uneven depth, and blurred edges. However, by selecting the right wood, optimizing processing parameters, and applying appropriate post-processing, these negative effects can be effectively mitigated and even transformed into unique artistic elements.

VI. How to Avoid Burn Marks When Using Laser Marking on Wood?

1. Optimizing Laser Processing Parameters (Core Method)

The key to effectively avoiding burns and excessive carbonization during wood laser marking lies in meticulously optimizing laser processing parameters. First, reduce the laser power. Through gradual testing (e.g., starting at 50%), find the critical value that achieves clear carbonization without burning through the material. This avoids localized overheating, burn spots, or even flames caused by excessive power. A "low-power, multiple-pass" strategy is recommended, as it is safer and produces more uniform results than single, high-power marking. Second, increasing the scanning speed (e.g., to 400–600 mm/s) can shorten the laser's dwell time per unit area, reduce heat accumulation, and prevent overheating. However, be aware that excessive speed can result in shallow marks, so this should be adjusted in conjunction with the power. Furthermore, appropriately increasing the pulse frequency (e.g., 10–20 kHz) can achieve more uniform energy distribution, reduce spot ablation, and achieve a smoother carbonization effect. Finally, precise focus must be ensured. Calibration using a focus test chart ensures that the laser beam is accurately focused on the wood surface. This avoids spot enlargement and energy dispersion caused by focus deviation, resulting in blurred edges or localized burns. This ensures clear, clean, and flawless marking quality.

2. Improving the Processing Environment and Auxiliary Measures

To effectively improve the quality and safety of wood laser marking, improving the processing environment and implementing auxiliary measures are crucial. First, a fume and dust removal system must be activated. Using a high-powered exhaust fan or central vacuum unit, fumes and combustible gases generated during processing are promptly removed. This not only prevents smoke and dust from adhering to the material surface and forming unsightly "smoke marks," but also significantly reduces the risk of fire. Secondly, it is recommended to install a compressed air auxiliary blower. Positioning a co-directional airflow nozzle near the laser head effectively removes combustion residue and prevents secondary combustion. This also provides localized cooling of the processing area, reduces the heat-affected zone (HAZ), and keeps the lens and optical path clean, thereby improving marking clarity and stability. Furthermore, continuous, intensive marking should be avoided, especially when filling large areas or engraving complex patterns. Intermittent processing is recommended to allow the wood time to dissipate heat. This prevents continuous heat accumulation, which can lead to an overall temperature increase and burns, discoloration, or even warping. This ensures a smooth, controllable process and a consistent finished product.

3. Material and Pretreatment Optimization

To ensure optimal wood laser marking results and minimize the risk of burns, carefully select suitable materials and perform appropriate pretreatment. Prefer woods with uniform grain and low resin content, such as maple, cherry, or medium-density fiberboard (MDF), as these materials are thermally stable and carbonize evenly. High-resin woods (such as untreated pine and fir) should be avoided, as their resins can easily burn and smoke at high temperatures, resulting in uneven blackening and even fire. Furthermore, the wood's moisture content should be kept between 8% and 12%. Excessive humidity can cause internal moisture to rapidly evaporate, causing cracking, splashing, or excessive smoke. Before processing, the wood surface should be sanded to remove burrs and unevenness to ensure uniform absorption of the laser energy. It should also be cleaned to remove impurities such as grease, dust, and other impurities to prevent localized burning. If necessary, a laser marking enhancer can be applied. This specialized coating increases the material's laser absorption, thereby reducing the required power and minimizing thermal damage. Furthermore, it is recommended to use high-temperature masking tape to mask non-processing areas to effectively prevent accidental burns caused by laser scatter or spatter, thus protecting the overall appearance of the wood and improving the quality of the finished product.

VII. The Application of CO2 Laser Marking Systems in Wood Processing

We are pleased to share practical application results from our customers! Numerous wood product manufacturers, handicraft designers, and packaging companies have adopted our CO2 laser marking machines to achieve high-precision, permanent, and artistically striking markings and engravings on their products.

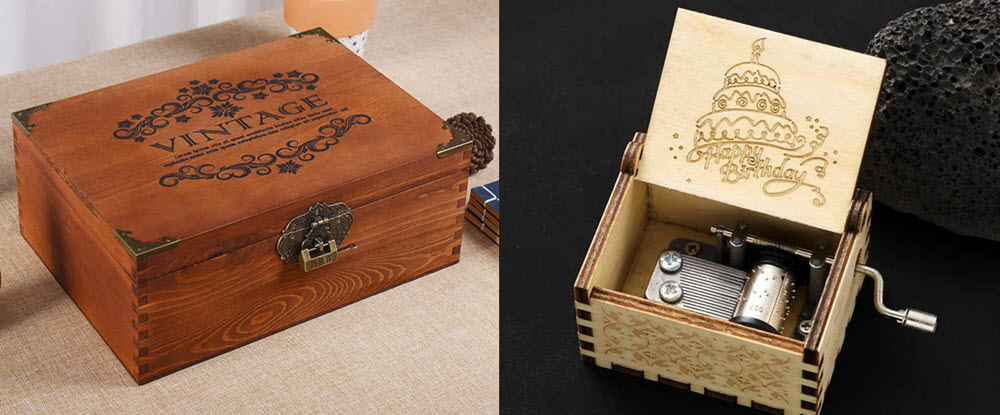

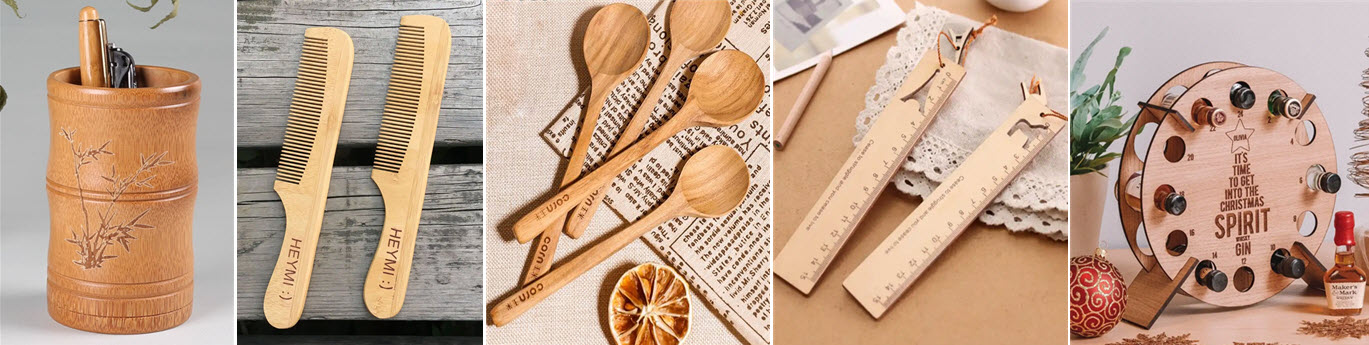

NITRATEK's customers use CO2 laser marking machines to achieve precise markings on a variety of wood products, fully demonstrating the equipment's superior processing capabilities for natural materials. In the bamboo product sector, some customers have successfully used lasers to clearly engrave text, patterns, or brand logos onto bamboo. The uniform carbonization effect highlights the natural texture and oriental charm of bamboo, such as bamboo slips, pen holders, and spoons. In the fine wood product sector, some customers have achieved personalized customization and shaping of products such as wooden boxes and combs through laser marking. The markings are permanent, wear-resistant, and do not detract from the overall aesthetic. Furthermore, this technology is widely used in small crafts such as wooden bookmarks, photo frames, and chess pieces. Whether it is subtle text or complex graphics, the markings are accurately rendered with smooth edges and rich details. These cases fully demonstrate the advantages of NITRATEK laser marking machines in wood and bamboo processing, with high precision, high efficiency, and high stability.

Wood laser marking is not only an upgrade for industrial marking, but also a perfect fusion of traditional craftsmanship and modern technology. Whether it is large-scale production that requires efficiency or personalized customization that emphasizes aesthetics, CO₂ laser marking machines provide precise, durable, and beautiful wood laser marking solutions. Choose a NITRATEK CO2 laser marking machine and let every piece of wood tell its own unique story. If you're looking for a wood laser marking solution, contact us today for free proofing and a customized configuration.