Leather Laser Marking

2025-07-23As consumers' demand for personalized, high-quality products continues to grow, traditional marking processes can no longer meet market requirements. Although traditional leather processing methods have a long history, they are gradually showing their limitations in the context of personalized needs and efficient production. Traditional methods such as hot stamping, screen printing or metal molding are gradually being replaced by a more accurate, environmentally friendly and flexible technology: leather laser marking machine. Whether it is a high-end leather brand or a small handicraft workshop, laser marking technology provides a unique marking solution for all kinds of leather materials with its advantages of efficiency, accuracy and environmental protection.

I. Working Principle of Leather Laser Marking

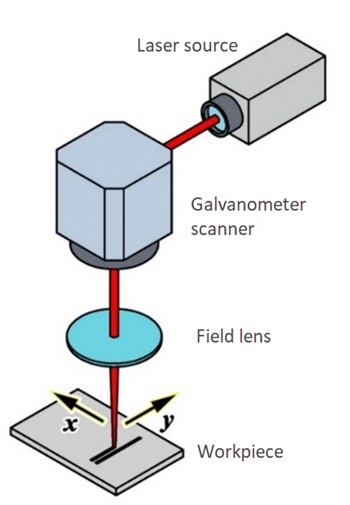

The leather laser marker uses a high-energy laser beam to generate local high temperature on the leather surface, thereby achieving the purpose of removing or changing the color of the leather surface. The built-in laser generator of the laser marking machine generates a laser beam of a specific wavelength (usually 355nm for ultraviolet laser marker and 10.6 microns for CO2 laser marker). After being adjusted by precision optical components such as beam expanders, galvanometers and focusing mirrors, the laser beam is focused on the leather surface with extremely high energy density. Depending on the laser power and scanning speed, different degrees of color change or etching effects can be formed on the leather.

1. Ablation/gasification: High energy density causes extremely thin materials on the leather surface (such as coatings, dyes or part of the fiber) to instantly heat up, carbonize or even directly vaporize and evaporate. After removing the surface layer, the leather base of different colors or textures is exposed, forming a clear contrast mark (such as a dark mark on light-colored leather).

2. Foaming/discoloration: At lower energy density, the laser mainly triggers a thermochemical reaction on the leather surface. Collagen in natural leather or polymer materials in synthetic leather decompose, oxidize or foam when heated, resulting in permanent color change (often turning brown, burnt yellow or forming a slight relief). This is a common way to achieve marking without significantly removing material.

3. Coloring: Certain specially treated leathers or with specific laser parameters can activate ingredients or added additives in the leather to produce new colors (such as light-colored marks).

For light-colored leather, low-power lasers are usually used for surface carbonization to form dark patterns; for dark leather, higher-power laser markers may be required to achieve clearly visible white or color marks. The computer control system (software) converts the designed graphics, text, serial numbers, QR codes and other vector files into control signals to drive the high-speed galvanometer motor to accurately deflect the reflector. The laser beam scans and moves point by point on the leather surface at high speed according to the set path, and finally "draws" a complete marking pattern.

II. Laser Marking Machines Can Mark Various Leather Products

Due to its non-contact, high-precision, high-flexibility and permanent marking characteristics, laser marking machines have a very wide range of applications in leather products, covering almost all leather product fields that require identification, decoration or functional marking. The following are some major application categories and specific examples:

1. Fashion accessories and bags: handbags, wallets, card holders, belts, watch straps: marking brand logos, models, exclusive names/abbreviations, personalized patterns or information, artistic patterns, serial numbers, anti-counterfeiting QR codes, production dates, etc. Laser markers can achieve fine engraving on different parts such as the body of the bag, lining labels, and the back of the belt buckle, etc., to enhance the brand image and personalized value.

2. Footwear: Laser marking machines can mark brand logos, sizes, models, origins, material information, QR codes (connecting product stories or anti-counterfeiting verification) on the inside of the tongue, insoles, sides, heels, etc. of leather casual shoes and boots. In addition, laser marking equipment can also mark brand logos, series names, limited numbers, personalized patterns or athlete signatures on synthetic leather/genuine leather sneakers, sandals, and slippers (especially suitable for customized and limited editions).

3. Clothing: Lasers can also mark brand logos, washing label information (ingredients, washing methods), decorative patterns, designer signatures or limited numbers on leather jackets, leather pants, and leather skirts. The fineness of the laser is suitable for marking on the inside or outside surface of the collar, cuffs, hem.

4. Furniture and home decoration: Lasers can mark brand logos, models, production batches, material certification marks, and even complex personalized decorative patterns, text or serialized marks in hidden or visible locations on sofas, seats, armchairs, cushions, etc. with genuine leather or PU leather finishes.

5. Car, yacht, and aviation interiors: On car seats (headrests, backrests, cushions), steering wheels, door trims, and central armrests, lasers can mark car brand logos, model logos, high-end version logos (such as "V6", "Limited Edition"), production serial numbers, safety certification marks, or add exclusive badges/names for high-end customized customers. This is a very important application area for laser marking, requiring extremely high wear resistance and aesthetics. On yacht/aircraft seats and interior panels, lasers can mark manufacturer information, customer customized logos, and other content.

6. Stationery and gifts: On leather notebook covers, diaries, photo albums, and high-end gift boxes, lasers can mark personalized names, messages, dates, company logos, complex art patterns, etc. These products are popular choices for business gifts and high-end stationery. Laser marking machines can also easily add small logos, abbreviations, or short greetings to leather key chains, bookmarks, and cup sleeves.

7. Horse equipment and pet products: Lasers are also used to mark the manufacturer's brand, rider's name, club badge or serial number on equestrian equipment such as saddles, reins, whips, etc. It is also used to engrave pet names, owner contact QR codes, pet hospital information, and decorative patterns on genuine leather or PU leather collars, leashes, and pet harnesses.

8. Sporting goods: On leather footballs, basketballs, rugby balls, and leather gloves (baseball, golf, cycling), lasers can mark brand logos, event logos, official certification information, models, sizes, personalized logos, etc.

9. Industrial and functional products: On the surface of leather tool bags, tool boxes, instrument protection boxes, and medical protective gear, lasers can mark brands, models, owners, numbers, etc.

...

Through laser marking, personalized customization can be achieved, and names, signatures, dates, unique numbers, etc. can be engraved on the surface of leather products to meet the personalized needs of consumers. At the same time, the permanent and clear brand logo, anti-counterfeiting QR code/serial number of leather laser marking helps to enhance brand image and combat counterfeiting. Marked production batch, date, material information, operating instructions, etc., to facilitate quality tracking and management.

III. Unique Advantages of Leather Laser Marking

Laser marking technology is widely used in the leather industry due to its significant advantages. Lasers can quickly engrave and hollow out various patterns on various leathers, and the operation is relatively flexible, while not causing any deformation of the leather surface, so as to reflect the color and texture of the leather itself.

1. Extremely fine and permanent: Lasers can engrave extremely fine lines, complex patterns, tiny texts and even high-resolution images (such as portraits, LOGO), with far greater accuracy than traditional methods. The mark penetrates deep into the shallow surface of the material, and is resistant to friction, washing and weathering, and will never fall off or fade.

2. Green and environmentally friendly: No ink, solvent, plate or mold is required throughout the process, chemical pollution is completely eliminated, and there is no VOC emission, which complies with increasingly stringent environmental regulations and consumers' demand for sustainable products.

3. Extraordinary flexibility: Through software control, different design contents can be switched instantly. It is particularly suitable for fast marking of small batch customization, personalized products (names, signatures, numbers), and variable data (dates, barcodes, QR codes).

4. Efficient automated integration: Fast marking speed (especially on simple patterns or serial numbers), easy to integrate into automated production lines, reduce manual intervention, and improve overall production efficiency and capacity.

5. Wide material adaptability: Whether it is natural leather (cow leather, sheepskin, pigskin, etc.), artificial leather (PU, PVC), suede or specially treated leather, by adjusting the laser parameters, you can usually find a suitable marking effect.

6. Improve product grade: The laser marking effect is exquisite and unique (such as the embossed feeling of foaming and the retro feeling of carbonization), which significantly improves the appearance texture and brand value of leather products.

IV. Technical Difficulties of Leather Laser Marking

Although leather laser marking machines have many advantages, they also face some challenges in practical applications. The following are some technical difficulties that need to be faced in practical applications:

1. Material difference processing: Due to the wide variety of leathers, including cowhide, sheepskin, pigskin and synthetic leather, the absorption coefficient and thermal conductivity of each material are different, so it is necessary to optimize the laser parameter settings for different leather types. In actual operation, we need to conduct detailed parameter testing and optimization (power, speed, frequency, defocus, fill line spacing, etc.) for each specific material.

2. Color consistency control: Lasers mainly produce "removal" or "thermochromic" effects, and the generated color range is limited (mainly brown, yellow, black, and white). Especially when marking colored leather, how to ensure that the color after marking is uniform and consistent without damaging the original color tone is a major problem. Accurately predicting and stably controlling the color and clarity of the final mark is extremely challenging, especially for customers with specific color requirements. Pre-treating the material or using special additives is sometimes a solution.

3. Engraving depth control: In order to obtain the ideal visual effect, the energy density and scanning speed of the laser must be precisely controlled to ensure that there is no excessive ablation and a clear mark is left at the desired location.

4. Marking on curved or irregular surfaces: Leather products are often three-dimensional (shoe uppers, bag bodies, seats). Flat marking machines may cause blurred, deformed or uneven energy marks on curved surfaces due to defocus. Therefore, a 3D dynamic focusing system (automatically adjusting the Z-axis focus) or robot arm integration is required to ensure uniform and consistent marking effects on complex curved surfaces.

Leather laser marking machines not only represent the direction of progress in modern manufacturing technology, but also bring unprecedented innovation opportunities to the leather products industry. For leather product manufacturers who want to stand out in the fierce competition, embracing this innovative technology means mastering the key ability to engrave a unique identity, excellent quality and contemporary value on the product, injecting eternal charm into each leather work. In the future, with the continuous improvement and perfection of related technologies, leather laser marking will become more popular and widely used in more fields.