Precision Pipe & Tube Laser Welding

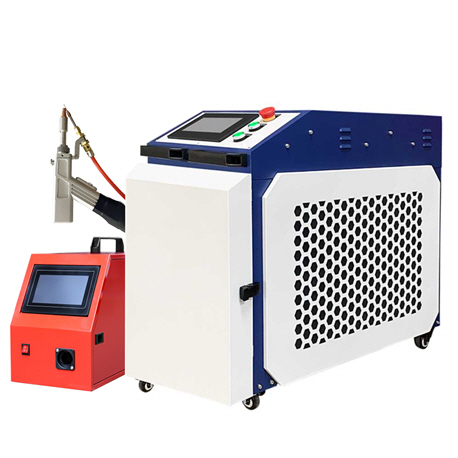

2025-07-25With the development of science and technology, laser technology is increasingly used in the field of metal processing. Especially in pipe processing, laser welding has become the new favorite of the industry with its high precision, high speed and flexibility. This article will introduce this advanced technology in detail from four aspects: the working principle, advantages, applicable materials and precautions of pipe & tube laser welding.

I. The Working Principle of Laser Pipe & Tube Welding

The core of laser tube welding is to use a focused high-energy-density and highly directional laser beam as a heat source for welding. In the process of laser tube welding, a high-quality laser beam with a specific wavelength (such as 1070nm for fiber laser) is first generated by a laser generator, and its path and focus position are precisely controlled by an optical system. The high-power-density laser spot is instantly irradiated on the area to be welded (butt joint or overlap) of the tube, and the metal material quickly absorbs the light energy and converts it into heat energy, and partially melts to form a molten pool. Under precise control, the laser beam (or workpiece) moves along the weld track. The molten pool moves with it, and the molten metal flows, mixes, and solidifies under the action of surface tension, gravity, etc., and finally forms a dense weld. During the welding process, an inert protective gas (such as argon, nitrogen, or a mixture thereof) is introduced to cover the molten pool and the adjacent high-temperature area, isolate the air, prevent oxidation and nitridation, and ensure the purity and surface quality of the weld. This process can be automated through programming to ensure the consistency and repeatability of tube welding.

II. Advantages of Pipes or Tubes Laser Welding

Compared with traditional arc welding such as TIG and MIG welding, laser welding machine has brought revolutionary improvements to tube & pipe processing. It has many unparalleled advantages:

1. Excellent welding quality: When using laser to weld pipes, the laser energy is highly concentrated, the input heat is small and precisely controllable, which significantly reduces the heat affected zone (HAZ), reduces the risk of thermal deformation, grain coarsening and material performance degradation. Laser welding can form deep and narrow welds on pipes with high welding strength and beautiful appearance. At the same time, the molten pool solidifies quickly, and the incidence of defects such as pores and slag inclusions is significantly lower than that of traditional welding methods. In addition, laser also has excellent advantages in welding pipes that require strict sealing, such as hydraulic pipes and refrigeration pipes, because it has excellent air tightness and water tightness, and the welds are dense and uniform.

2. High welding efficiency: Compared with other welding methods, laser welding of pipes is faster and the production efficiency is significantly improved. Laser welding can also be seamlessly integrated with robots and CNC systems to achieve high-speed, fully automatic pipe production lines.

3. Excellent process flexibility: Laser welding machine supports welding of pipes or tubes made of various metals and aluminum alloys to meet customers' diverse welding needs. In addition, due to the flexible guidance of the beam, laser welding can achieve circumferential welding, spatial curve welding, welding of difficult-to-access positions, and supports welding of straight and complex curved pipes. It has strong adaptability and can handle a variety of complex welding tasks.

4. High precision and controllability: Laser welding can achieve precise energy control to adapt to pipes of different wall thicknesses and materials by adjusting laser power, frequency, pulse width and other parameters. The use of modern advanced optical systems can achieve precise positioning to ensure that the beam acts accurately on a small area.

5. Low subsequent processing costs: Since laser welding has little deformation, the correction process can be reduced or even omitted, saving time and labor costs. Laser welding has less spatter, beautiful welds, and less post-weld cleaning work, and sometimes it can be used directly.

III. Laser Machine Can Weld Pipes and Tubes of Various Materials

Laser welding technology has a wide range of material compatibility and can efficiently connect a variety of metal pipes, such as round, square, oval and other shaped parts made of low alloy steel, stainless steel, carbon steel, 5A06\6061 aluminum alloy and other materials.

• Stainless steel pipe: Due to its good corrosion resistance and mechanical properties, it is widely used in chemical, food processing and other industries. It is the most mature application field of laser welding, such as welding food and beverage equipment pipelines, biopharmaceutical pipelines, chemical pipelines, automobile exhaust systems, decorative pipes, etc. (mainly austenitic 304, 316L, etc.).

• Carbon steel pipe/low alloy steel pipe: Laser can also be used for welding automotive parts (such as drive shafts, fuel rails), hydraulic oil pipes, structural parts, etc.

• Aluminum alloy pipe: Its light weight and high strength make it one of the preferred materials in the aerospace and automobile manufacturing fields. It requires high beam quality and specific protective gases (such as helium) and is used in new energy vehicle battery pack shell connection pipes, aerospace pipelines, bicycle frames, etc. (such as 5xxx, 6xxx series).

IV. Key Considerations for Laser Welding of Pipes and Tubes

In order to give full play to the advantages of laser welding and ensure the best welding effect, we need to focus on the following matters:

• Strict cleanliness requirements: In order to ensure the best welding quality, oil, grease, oxides, coatings, moisture and other pollutants in and near the pipe area to be welded must be thoroughly removed before welding. Pollutants can cause defects such as pores, spatter, and unfused.

• Precise process parameter control: Laser power, welding speed, defocus, spot size/mode, pulse parameters (when pulse welding), etc. must be accurately matched and optimized according to the pipe material, wall thickness, diameter, and joint form, and ensure the stability of process parameters in long-term production.

• Safety protection measures: Laser is a strong light source and can cause harm to the human body. Therefore, during the welding of pipes, operators should wear appropriate protective glasses and gloves and other necessary shielding measures to prevent direct damage.

• Post-weld inspection: Implement strict non-destructive testing (such as X-ray, ultrasonic, pressure test, air tightness test) to ensure that the weld quality meets the standards.

• Regular maintenance: Keeping the laser welding equipment in good condition is essential to maintaining stable and efficient welding. Therefore, we need to regularly inspect and maintain the equipment, including checking the optical components, welding guns, calibrating the system accuracy, etc.

Pipe & tube laser welding technology has become a key technology in the field of modern tube manufacturing due to its high efficiency, high quality, low deformation and high degree of automation. With the continuous improvement of laser performance and the increasing maturity of technology, its application scope is rapidly expanding to high-tech industries such as automobiles, aerospace, medical, and new energy. A deep understanding of its working principle, grasping its core advantages, clarifying the scope of applicable materials, and strictly abiding by operating specifications and precautions are the fundamental guarantees for the successful application of this technology and the production of high-quality pipe products that meet stringent requirements. Laser welding is constantly pushing the tube processing technology towards a more precise, smarter, and greener direction. If you are interested in a handheld fiber laser welding machine, please feel free to contact us.