Handheld Metal Laser Welding

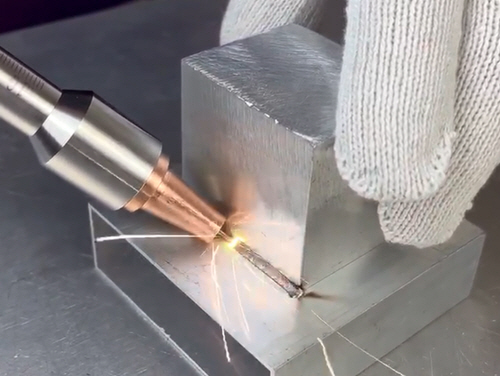

2025-09-05Handheld laser welding technology is reshaping the metalworking industry at an unprecedented pace. It transcends the limitations of traditional welding processes in terms of precision, thermal impact, and flexibility. With its high-precision control, low heat input, excellent weld quality, and exceptional operational adaptability, it has rapidly become a key technology of choice in the manufacturing industry. In this article, we will explore the core advantages and applications of handheld metal laser welding systems, including their wide range of metal material compatibility, flexible and diverse welding path control capabilities, and their extensive applications and promising prospects across various industrial sectors.

What Types of Metals Can be Welded by Handheld Laser Welders?

Handheld laser welders are highly flexible and efficient welding tools suitable for welding a wide range of metals. The following is an introduction to the suitability of handheld laser welding for several common materials:

1. Stainless steel: Laser welding is well-suited for welding stainless steel, whether austenitic (such as 304, 316), ferritic, or martensitic. High-quality, distortion-free welds are achieved, and the weld area is smooth and corrosion-resistant.

2. Galvanized steel: Due to the presence of the zinc layer, defects such as porosity may occur during welding. However, by adjusting welding parameters, such as reducing power density and using an appropriate welding speed, these issues can be effectively reduced, achieving good welds for galvanized steel.

3. Carbon steel: Laser welding can be used to create high-strength joints for both low-carbon steel (such as Q235) and medium-carbon steel. For high-carbon steel, careful control of heat input may be necessary to prevent crack formation.

4. Aluminum and aluminum alloys: Although aluminum and its alloys have high reflectivity and good thermal conductivity, technological advancements have enabled modern handheld laser welders to effectively weld these materials. The key lies in selecting the correct laser wavelength and power, as well as optimizing the welding process parameters.

In summary, handheld laser welders can be used for welding all of the materials mentioned above. However, in practice, different welding parameters, such as laser power, welding speed, and focal diameter, may require adjustment based on the material's characteristics to ensure optimal weld quality and efficiency. Furthermore, the use of shielding gas or other auxiliary methods may be necessary to achieve optimal welding results.

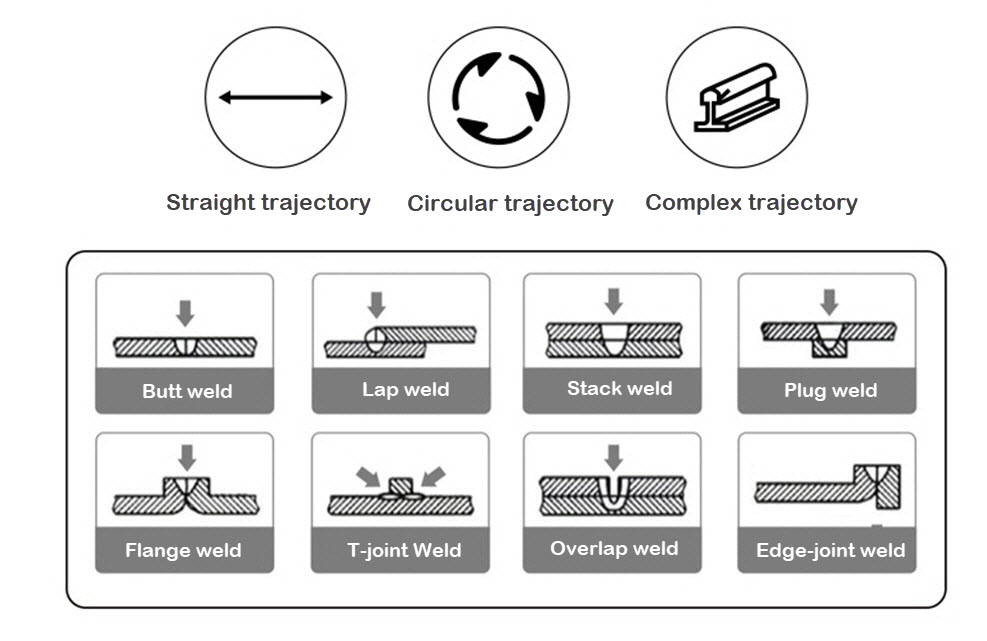

Handheld Laser Welders Support Various Metal Welding Trajectories

Handheld laser welders, with their flexibility and precision, offer unique advantages in welding metals using a variety of trajectories. Whether it's a straight line, a curve, or a complex three-dimensional path, handheld laser welders can achieve high-quality welds. Their unparalleled flexibility supports nearly any weld trajectory imaginable:

1. Straight trajectory: For simple straight welds, handheld laser welders can complete the process with exceptional speed and precision, ensuring uniform and aesthetically pleasing welds.

2. Curved/contoured trajectory: Easily handle welding of round, curved, or irregularly shaped workpieces (such as flanges, pipe fittings, and decorative parts) with the freedom of a paintbrush. When working with curved welds, the operator can easily follow the desired path with the handheld device. This flexibility enables high-quality welds even on complex workpieces.

3. Complex 3D trajectory: The lightweight handheld welding torch allows welders to move freely within three-dimensional space, easily completing welds around complex curves, corners, and multiple angles (e.g., auto body repair and sculpture welding). This opens up new possibilities for the fabrication of complex structural components.

4. Confined space operation: The compact size of the torch allows for precise welding in tight spaces or inside equipment that are difficult for traditional torches to reach. The compact design of the handheld device allows operators to flexibly adjust the angle and position of the welding head for precise welding of irregular shapes or difficult-to-access locations.

5. Oscillating welding: The built-in oscillation function of the torch head effectively widens the weld seam, improves bridging, refines grain size, and reduces porosity, making it particularly suitable for welding aluminum alloys or joints with slightly larger gaps.

This freedom of trajectory significantly frees up design and manufacturing constraints, making complex structures, art restoration, and on-site repairs feasible and efficient. Handheld laser welders can easily help you perform butt welding, lap welding, stitch welding, nail welding, flange welding, T-weld welding, lap welding, and edge welding. In short, handheld laser welders greatly expand the possibilities of metal processing through their diverse welding trajectory capabilities, excelling in both simple and complex welding tasks. This technological advancement not only improves production efficiency but also enhances the quality of the final product.

The Widespread Applications and Prospects of Metal Laser Welding

Handheld metal laser welding technology, with its revolutionary flexibility and industrial-grade precision, is liberating laser welding from fixed workstations to be used on the production line, at repair sites, and even outdoors, becoming an indispensable mobile solution for the intelligent transformation of manufacturing. Its applications have permeated a wide range of industrial operations and demonstrate broad innovative prospects.

1. Industrial On-site Repair

In automobile manufacturing workshops, workers use handheld laser welding torches to precisely repair body defects, minimizing the heat-affected zone to the millimeter level to avoid damaging the surrounding electrophoretic coating. Engineers repair mold chipping on-site at 10,000-ton injection molding machines without disassembly, achieving weld strength comparable to the base material and reducing downtime by 90%.

2. Free Creation of Complex Structures

Handheld laser welders are also widely used for joining curved surfaces in artistic metal sculptures, repairing bronze ornaments on ancient buildings, and repairing aluminum alloy yacht hulls. Handheld laser welding, like a "metal suture needle," achieves welding along arbitrary paths in three dimensions, navigating narrow corners (such as pipe walls and equipment interlayers) that are inaccessible to traditional welding torches.

3. Mobile Workstations for the New Energy Industry

During on-site installation of photovoltaic racks, lap welding of galvanized steel sheets no longer requires large equipment. Wind turbine tower weld repairs eliminate the need for hoisting or disassembly. During emergency repairs of electric vehicle battery packs, the sealing welding of aluminum casings can be completed in 10 minutes, achieving IP67 airtightness.

4. Flexible Welding in Micro-Manufacturing Industries

Hardware workshops use handheld laser welders to weld stainless steel security windows, achieving speeds three times faster than argon arc welding without distortion. Sheet metal shops use metal laser welders to process custom-shaped ventilation ducts, achieving smooth welds without the need for grinding and eliminating the need for polishing.

Handheld laser metal welders are profoundly revolutionizing metal joining processes with their wide range of metal compatibility (covering stainless steel, carbon steel, and aluminum alloys), unparalleled trajectory flexibility (capable of handling straight and curved lines, complex 3D shapes, and confined spaces), and widespread application across a wide range of industries (from industrial manufacturing to precision maintenance, from automotive to medical). It perfectly combines efficiency, precision, aesthetics, and flexibility, providing a powerful solution for modern manufacturing and making it a well-deserved innovator in metal joining technology. With the continuous optimization of equipment costs and continuous advancement of technology, its application prospects will be even broader.