Barcode & QR Code Laser Marking

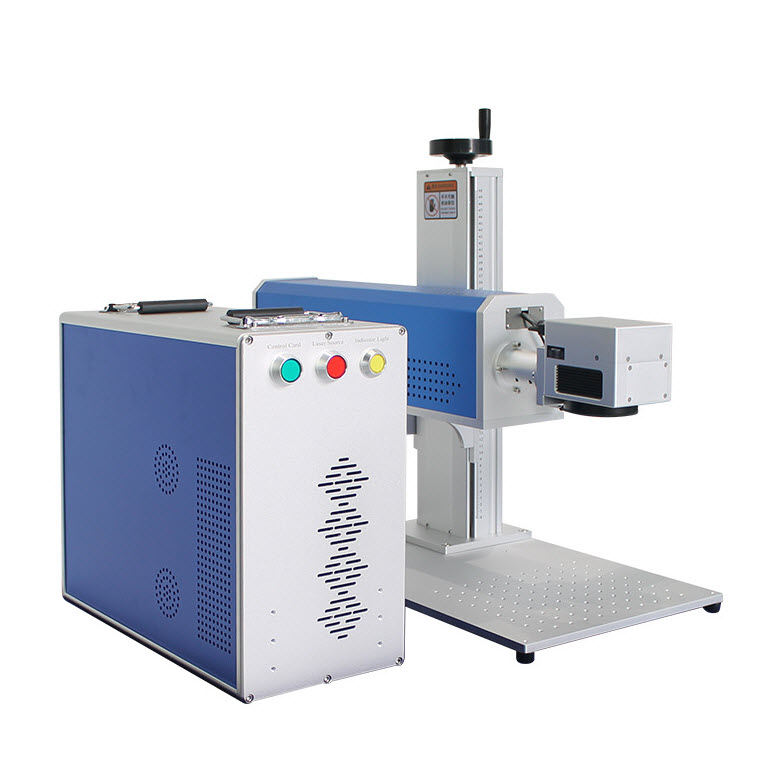

2025-07-14In the manufacturing and logistics industries, barcodes and QR codes play a vital role as information carriers. They not only improve the speed and accuracy of data processing, but also greatly enhance the traceability and safety of products. With the development of laser technology, laser markers have become one of the preferred tools for marking barcodes and QR codes. This article will introduce the core working principles, applicable materials, unique advantages and wide applications of barcode and QR code laser marking in detail, and share the selection points to help you choose the right barcode and QR code laser marking equipment.

I. Basic Working Principle of Laser Marking Barcodes and QR Codes

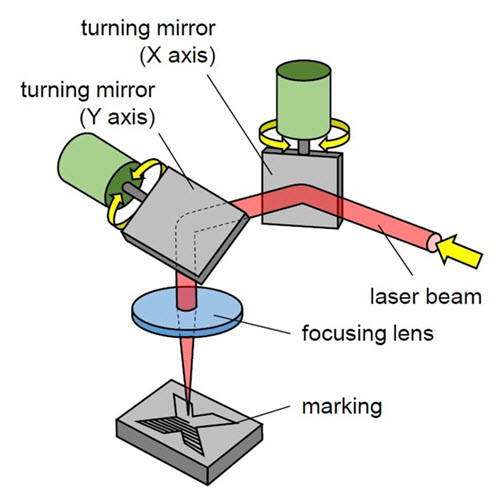

The core of laser marking barcodes or QR codes lies in the precise interaction between high-energy-density laser beams and the surface of materials. The laser generates a beam of light of a specific wavelength (such as 1064nm for optical fiber, 10.6μm for CO₂, and 355nm for ultraviolet), which is focused into an extremely fine spot by the optical system. The high-energy-density laser beam is focused on the surface of the material. The laser energy interacts with the material, causing physical or chemical changes on the surface of the material. For example, the laser energy causes the thin layer of the surface of metal and hard plastic to be ablated or vaporized to form a concave mark, the laser heats the surface of stainless steel to cause oxidation and discoloration to produce a dark mark, and the laser causes the surface of light-colored plastics, wood, paper and other organic materials to carbonize and turn black to form a mark... The laser marking machine accurately controls the path of the laser beam through the galvanometer scanning system to outline the pattern of the barcode or QR code on the surface of the material.

II. What Types of Barcodes and QR Codes Can Be Marked by Laser Marking Machines

Whether it is traditional linear (one-dimensional) barcodes or modern matrix (two-dimensional) QR codes, laser marking machines can do the job. Laser marking technology, with its high precision and flexibility, can perfectly present almost all mainstream one-dimensional and two-dimensional codes:

Applicable barcode types:

1. Code 128:the most widely used barcode.

2. EAN-8 and EAN-13: international product codes.

3. UPC-A and UPC-E: retail product codes.

4. Code 39: widely used in the industrial and logistics fields.

5. ITF-14: used in the logistics packaging industry.

6. Codabar: libraries, blood banks.

…

Applicable QR code types:

1. QR Code: quick response code, the most widely used.

2. Data Matrix: high information density, especially for small-sized workpieces such as electronic components.

3. MaxiCode: logistics packages.

4. Aztec Code: tickets, transportation.

These common barcode types can all be marked with high quality through laser marking technology. This makes laser marking an ideal choice for a variety of application scenarios, from retail product identification to industrial product tracking. Lasers are particularly good at marking high-density, small-sized QR codes (such as Data Matrix), and their fine focusing ability ensures that tiny units are clearly identifiable and meet stringent read rate requirements.

III. What Materials Can Laser Marking Machines Engrave Barcodes and QR Codes On?

Laser marking technology is suitable for engraving barcodes and QR codes on almost all common types of material surfaces:

1. Metal materials: stainless steel, aluminum, copper, titanium, galvanized sheet, anodized aluminum, etc.

2. Plastics: ABS, PC, PP, PE, PVC, POM, plastics with fillers (glass fiber reinforced, etc.), special engineering plastics, etc.

3. Ceramics.

4. Glass.

5. Coated/painted surfaces: such as removing the surface layer to reveal the base color.

6. Some rubber and silicone.

7. Organic materials: such as wood, paper, leather...

Different types of laser marking machines such as fiber laser marking machines, CO₂ laser marking machines, and UV laser marking machines have the best effects for different materials, ensuring that the marking is both beautiful and durable, meeting your barcode and QR code engraving needs.

IV. What Are the Advantages of Using Laser to Mark Barcodes and QR Codes?

Laser marking is a very popular and efficient industrial marking method, especially suitable for application scenarios that require permanent, clear and traceable identification. Laser marking barcodes and QR codes have many advantages over traditional printing methods:

1. Permanence: Laser marking is a physical or chemical change that penetrates into the surface of the material or changes its properties. It is extremely wear-resistant, corrosion-resistant, solvent-resistant, high-temperature-resistant, and not easy to be erased or tampered with.

2. Non-contact: The laser beam does not contact the surface of the workpiece, there is no mechanical stress, and it will not damage delicate or fragile parts.

3. High precision/high quality: Laser marking can generate very fine and sharp-edged lines and dots. Even high-density small-size barcodes (such as Data Matrix QR codes) can be clearly marked to ensure high read rates.

4. High speed and efficiency: The marking process is usually very fast, especially suitable for high-speed marking needs on automated production lines.

5. Flexibility and programmability: The marking content (barcode data, serial number, etc.), format (1D barcode type, 2D code type), font, size, and graphics can be easily changed through the built-in software.

6. Environmentally friendly and low operating cost: No ink, solvent, consumables (such as labels, ribbons) are required, reducing waste and operating costs, and the cost of consumables is almost zero.

7. Wide range of material applicability: metal, plastic, ceramic, glass, wood, leather, paper, etc.

8. Anti-counterfeiting: Permanent and clear QR code and barcode marking has a certain anti-counterfeiting effect.

These unparalleled advantages have made the laser marking machine the preferred tool for marking barcodes and QR codes. It can help you engrave barcodes, numbers, patterns, letters, etc. that meet your expectations on products of different shapes and sizes.

V. Laser-Marked Barcodes and QR Codes Are Widely Used in Multiple Industries

As an important technical support for intelligent manufacturing and product traceability systems, laser-marked barcodes and QR codes have been widely used in multiple industries:

1. Electronic products: can be used for serial numbers, certification marks and traceability QR codes on PCB boards, chips, resistors and capacitors, connectors, and mobile phone and computer shells.

2. Automobile manufacturing: suitable for permanent part numbers and traceability codes on engine parts, vehicle frame numbers (VIN), gearboxes, sensors, wiring harnesses and plastic interior parts.

3. Medical devices: mark UDI unique device identification, batch number and expiration date on surgical instruments, orthopedic implants, diagnostic equipment and consumables to meet sterile and permanent requirements.

4. Aerospace: Laser marking can achieve accurate identification of high-value and high-safety components such as engine blades, landing gear, avionics equipment, etc.

5. Tools and hardware: drills, knives, wrenches and measuring tools can also be laser-marked with clear brand, model, specifications and anti-counterfeiting information.

6. Food and beverage packaging: Laser marking machines can mark production date, expiration date, batch number and traceability QR code on glass bottles, metal cans, plastic bottles and bottle caps, and comply with food safety contact regulations.

7. Daily chemical products: For example, batch, date, promotional QR code and anti-counterfeiting information can be clearly marked on plastic bottles, tube cans and metal cans.

8. Cables: The outer sheath of wires and cables can also be marked with specifications, lengths, certification marks and meter marks by laser marking.

9. Jewelry: Brand LOGO, ingredient identification and unique anti-counterfeiting code at the micro-carving level on precious metal materials.

10. Logistics warehousing: Laser marking machines can also be used to mark tracking management barcodes on pallets, turnover boxes and shelves.

With its advantages of high precision, non-contact and strong durability, laser marking has become an indispensable means of information identification in modern industry.

VI. How to Choose the Most Suitable Type of Laser Marking Machine to Mark Barcodes and QR Codes?

Before you choose a laser marking device, you may wish to look at the following points, which may help you select the most suitable laser marking machine to help you present perfect barcodes, QR codes, logos and other information:

1. Material type: This is the first point you need to consider. Because different laser types of marking machines have very different marking effects on different material surfaces. If you plan to engrave QR codes or barcodes on metal or hard plastic surfaces, then a fiber laser marking machine with a wavelength of 1064nm is definitely your best choice. If you plan to achieve barcode marking on wood, paper, acrylic, leather, and most organic materials, then a CO2 laser marking machine with a wavelength of 10.6μm can bring you the best results. For heat-sensitive materials (such as flexible circuit boards FPC, films, some plastics such as PE/PP), glass, and marking requirements that require extremely high contrast, a UV laser marking machine with a wavelength of 355nm will be your best choice. For highly reflective metals (gold, silver, copper) and some special plastics, 532nm green laser markers and UV laser markers can provide you with the best marking results.

2. Barcode and QR code marking requirements: For marking tiny, high-density QR codes, such as <3mm Data Matrix, UV lasers have the most advantages due to their fine spot and "cold processing". UV and green light usually perform better for high contrast on light-colored or difficult-to-mark materials.

3. Marking speed and production requirements: If your production line speed requirements are high, you need to choose a laser with sufficient power (such as a higher wattage fiber laser) and a high-speed galvanometer system. If you want to achieve online high-speed marking, then the fiber laser marker will definitely be a good choice due to its strong anti-interference, stable performance, and rich integrated interfaces (I/O, communication protocol).

4. In addition to the above factors, you also need to choose the most suitable equipment based on the actual budget and operating costs. The prices of different types of laser markers vary greatly, and you need to choose according to your actual needs.

Laser marking technology provides strong support for efficient and accurate marking of barcodes and QR codes. Its wide application is changing the data management and product identification methods of various industries. It perfectly combines precision, efficiency, environmental protection and permanence, and has become the core force driving the intelligentization, traceability and anti-counterfeiting upgrades of modern industry. By reasonably selecting laser marking equipment that suits their needs, enterprises can not only improve production efficiency, but also enhance product quality and market competitiveness. With the continuous advancement of technology, laser marking will show its unlimited potential in more fields in the future.