Frequently Asked Questions About Laser Rust Removal

2025-10-29In fields such as industrial manufacturing, equipment maintenance, cultural relic restoration, and marine engineering, metal surface corrosion has long plagued technicians. While traditional rust removal methods such as sandblasting and pickling are effective, they pose challenges such as environmental pollution, substrate damage, and operational hazards. With the advancement of laser technology, laser rust removal, as an emerging green cleaning method, is gradually replacing traditional processes and becoming the preferred choice for metal surface treatment. This article will comprehensively answer the most pressing questions from our customers. If you are looking for laser rust removal systems, equipment, or solutions, we hope this article will provide some helpful insights.

I. Can Lasers Remove Rust? How Do Laser Rust Removal Systems Work?

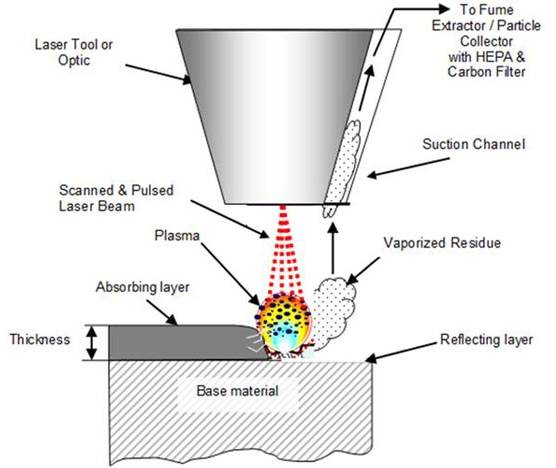

Laser cleaners can certainly be used for rust removal. Currently, laser rust removal is widely used in areas such as ships, bridges, railways, aerospace, molds, pipelines, and cultural heritage preservation. The core of laser rust removal is the use of a high-energy-density laser beam to illuminate a metal surface. Its working process is not a single mechanism, but rather the result of a combination of physical effects. Lasers are intense beams of light of a specific wavelength. When they strike a rusted metal surface, contaminants such as rust (oxides), paint, and oil absorb the laser much more rapidly than the underlying metal substrate. After absorbing most of the laser's energy, the contaminants rapidly heat up. This can lead to several conditions:

● Vaporization/ablation: If the energy is high enough, the contaminants can be heated directly to above their boiling or ignition points, instantly vaporizing or burning into gases and tiny particles.

● Thermal expansion and delamination: Even before vaporization, the intense thermal expansion can cause loosely attached rust and paint layers to crack and peel away from the solid metal surface due to uneven stress.

● Sonic Shattering Effect: At the moment the laser interacts with the material, some of the energy is converted into intense shock waves (sound waves). When these sound waves reach the interface between the rust layer and the metal, they reflect and interfere, creating powerful vibrations that further break up and peel away stubborn rust.

The laser rust removal process is primarily as follows:

- Targeting: The high-energy laser beam is focused on the area to be cleaned.

- Absorption: Surface rust and dirt absorb the laser energy, while the metal substrate absorbs very little.

- Destruction: Dirt is destroyed by vaporization, ablation, or thermal expansion.

- Stripping: The combined effects of heat and shock waves lift dirt away from the metal surface.

- Cleaning: The generated smoke and particles are promptly removed by the accompanying exhaust system (vacuum cleaner), leaving a clean metal surface.

Laser rust removal utilizes the difference in laser absorption capacity between pollutants and substrates, as well as the difference in ablation thresholds between the two. Through the multiple effects of thermal effects, shock waves, etc. generated by high-energy laser beams, only rust, oil stains or old coatings on the surface are removed, while the underlying metal body is preserved intact.

II. What Are the Differences Between Laser Rust Removal and Chemical Rust Removal?

Laser rust removal and chemical rust removal are two distinct rust removal methods, with significant differences in their principles, effectiveness, environmental friendliness, and cost. The following are the main differences:

● Different Basic Principles

Laser rust removal: A high-energy-density laser beam is used to irradiate the metal surface. Because contaminants like rust absorb the laser light at a much higher rate than the metal substrate, the contaminants absorb the energy and are quickly vaporized, ablated, or removed due to thermal expansion. This is a physical process.

Chemical rust removal: A chemical agent, such as an acid (such as hydrochloric acid or sulfuric acid) or an alkaline cleaning agent, reacts with the rust, converting the water-insoluble trivalent iron oxides into a water-soluble substance that is then removed by washing. This is a chemical dissolution process.

● Impact on the Workpiece

Laser rust removal:

Non-contact: The laser beam does not directly contact the workpiece, so it will not scratch or abrade the substrate.

Protecting the substrate: By precisely controlling the laser energy, only the rust layer can be removed without damaging the intact metal. No Risk of Hydrogen Embrittlement: Unlike pickling, it does not cause hydrogen embrittlement (hydrogen atoms penetrate into the metal, making it brittle).

Chemical Rust Removal:

Possible Corrosion to the Substrate: The acid not only dissolves rust but also slowly corrodes the metal itself, especially if the treatment is prolonged.

Possible Risk of Hydrogen Embrittlement: The hydrogen gas generated during the pickling process may penetrate into the steel, reducing its toughness.

Possible Marking: Sometimes dark spots or light marks may be left, or the adhesion of subsequent coatings may be affected.

● Efficiency and Operation

Laser Rust Removal:

High Efficiency: Highly automated and can be connected to robots for assembly line operation. For example, a 2000W laser can process approximately 60 square meters per hour.

Easy to Operate: The handheld device is similar to a power drill, with a short learning curve and easy automation.

Chemical Rust Removal:

Low Efficiency: Requires multiple steps, including soaking, scrubbing, rinsing, neutralization, and drying, making the process cumbersome and time-consuming. Complex operation: Protective clothing, gloves, and a mask are required to prevent acid burns and inhalation of harmful gases.

● Environmental Protection

Laser rust removal: Green and environmentally friendly. It primarily consumes electricity and produces no wastewater, exhaust gas, or chemical waste. The only byproduct is a small amount of collectible dust.

Chemical rust removal: Severely polluting. It produces large amounts of wastewater containing heavy metal ions and acids and alkalis, which must undergo expensive treatment before discharge, otherwise it will seriously pollute the environment.

● Scope of Application

Laser rust removal: Suitable for workpieces of various shapes, especially precision parts, molds, cultural relic restoration, and hard-to-reach areas (when used with robots). It is the preferred choice for applications sensitive to environmental pollution.

Chemical rust removal: Suitable for batch processing of small, regular parts, but inconvenient for large structures or on-site operations.

Laser rust removal is an efficient, precise, and environmentally friendly "future technology." While initial investment is high, long-term operating costs are low, making it particularly suitable for large-scale, high-quality industrial applications. Chemical rust removal is a traditional, low-cost entry-level method, but it has problems with pollution, safety risks and possible damage to workpieces. It is more suitable for small-scale, occasional rust removal needs.

III. What Are the Unique Advantages of Laser Rust Removal Over Traditional Rust Removal Methods?

Compared to traditional methods like mechanical grinding, sandblasting, and chemical pickling, laser rust removal technology, thanks to its unique physical working principles, offers significant advantages in many areas and is revolutionizing the industrial cleaning industry. Its key advantages are as follows:

● High Rust Removal Efficiency

Fast Speed: The high-power laser beam releases enormous energy in a very short time, directly targeting the rusted area and rapidly removing it like an "invisible brush," eliminating the need for pretreatment.

Time and Labor Saving: Compared to traditional methods that require repeated grinding or prolonged soaking, laser rust removal significantly reduces processing time. It is particularly suitable for large-scale rust removal projects such as those on large steel structures, ships, and bridges, significantly improving production efficiency.

● Environmentally Friendly

No Chemical Reagents: No chemicals such as acids or alkalis are used, eliminating the wastewater, exhaust gas, and chemical residue issues associated with traditional chemical rust removal.

No Dust Pollution: Unlike sandblasting, which produces large amounts of harmful dust, laser rust removal produces only a small amount of solid particles that can be collected by the exhaust system, minimizing impact on the air and the environment. Green Cleaning: The entire process consumes only electrical energy, complying with increasingly stringent environmental regulations and sustainable development requirements.

● Protecting Substrate Integrity

No Damage to the Substrate: The laser beam does not directly contact the workpiece surface. Through precisely controlled energy, it only removes rust without scratching, abrading, or deforming the intact metal.

Avoiding Secondary Damage: It eliminates surface scratches caused by traditional mechanical grinding and the potential for media embedding or substrate fatigue caused by sandblasting, perfectly preserving the original dimensions and precision of the workpiece.

● High Precision, Suitable for Complex Structures

Flexible and Controllable: By adjusting laser parameters (power, frequency, and scanning speed), the cleaning depth and range can be precisely controlled, achieving selective cleaning.

Handling Complex Workpieces: The laser beam can precisely reach complex structures with grooves, gaps, curved surfaces, and other difficult-to-reach structures, ensuring uniform cleaning and providing an ideal substrate for subsequent coating, welding, and other processes.

● Easy Operation

Easy to Use: Modern laser rust removing system often uses intelligent operating systems with user-friendly interfaces, making it easy to master with minimal training. Handheld and Flexible: The handheld design allows operators to easily move the device for comprehensive cleaning of large or fixed workpieces, reducing labor intensity.

● Low Maintenance Costs and Significant Long-Term Benefits

Low Consumables: The primary consumption is electricity, eliminating the need for consumables such as abrasives and chemicals.

Long Life: The device itself offers a long service life and simple maintenance, resulting in long-term operating costs significantly lower than traditional methods.

High Overall Benefits: While the initial investment is high, its high efficiency, environmental friendliness, and low maintenance can bring significant economic benefits and return on investment to businesses.

Laser rust removal technology combines high efficiency, environmental friendliness, precision, safety, and low maintenance. It is not only an advanced rust removal tool, but also represents an efficient, clean, and sustainable modern production method. It is gradually replacing traditional methods and becoming the preferred rust removal and maintenance solution for high-end manufacturing, large-scale infrastructure, and precision industry.

IV. What Are the Limitations of Laser Rust Removal?

Although laser rust removal technology offers significant advantages such as high efficiency, environmental friendliness, and non-contact operation, it also presents some limitations and challenges, primarily in the following areas:

● High operation difficulty:

Parameter adjustment for laser rust removal systems is complex. Achieving optimal cleaning results without damaging the substrate requires specialized operator expertise to adjust parameters such as laser power, pulse frequency, scanning speed, and spot size. These parameters must be precisely tailored to factors such as the workpiece material, rust severity, and surface topography. Untrained operators can easily misconfigure parameters, resulting in incomplete cleaning or burns to the metal substrate, increasing the risk of rework.

● Processing efficiency is affected by specific conditions:

Reduced efficiency with thick rust layers: For very thick, dense, or large rust layers, laser treatment may require multiple scans to completely remove them, making it less efficient than aggressive mechanical grinding or sandblasting.

● Limitations with complex geometries:

The laser beam is linear, making it difficult to reach deep holes, grooves, narrow gaps, or obstructed "shadow areas." When processing workpieces with extremely complex shapes, multi-axis robots or manual intervention are often required, making 100% automated coverage impossible.

● Sensitive to material properties:

Laser rust removal systems are less effective on highly reflective materials. Non-ferrous metals such as aluminum, copper, and brass have high reflectivity and low absorption of near-infrared lasers (such as the commonly used 1064nm fiber laser), resulting in inefficient cleaning and even possible damage to the laser rust removal equipment. These materials typically require pretreatment (such as applying an absorptive coating) or the use of lasers with specialized wavelengths.

● Effectiveness varies depending on the type of rust:

Lasers are excellent for removing loose, floating rust, but may be less effective against some tightly bound oxides or complex contaminants.

Laser rust removal is an advanced technology, particularly suitable for applications requiring high precision, environmental protection, and high-value substrates. However, when choosing a laser, one must weigh its high cost, demanding operating requirements, and limitations when working with thick rust layers and complex structures. It is not a panacea, but rather a powerful supplement or upgrade to traditional cleaning methods.

V. What Metals Are Suitable for Laser Rust Removal?

Laser rust removal technology has broad applicability and can be applied to a variety of metals. However, its effectiveness varies depending on the metal's optical properties (such as reflectivity) and thermal sensitivity. The following are the main applicable metals and their characteristics:

● Carbon steel and alloy steel: These are the most common targets for laser rust removal, offering excellent rust removal results.

● Stainless steel: Lasers can remove rust, weld stains, scale, and old coatings from stainless steel surfaces.

● Copper and aluminum alloys: These two materials have high reflectivity and low absorption for near-infrared lasers (such as 1064nm). Therefore, higher power or specialized wavelengths (such as green or ultraviolet lasers) are required for improved efficiency. Furthermore, energy must be carefully controlled to avoid localized overheating that could cause surface melting or deformation.

● Titanium alloys: Used for precision cleaning of aerospace components. After laser cleaning, titanium alloy surfaces may develop oxidation discoloration, sometimes requiring subsequent passivation treatment.

VI. Does Laser Damage Metal?

Laser can damage metals under certain conditions, but when used correctly, it can be done without damaging the metal substrate. This depends on the laser's parameter settings and operation. Simply put, a laser can be both a "destroyer" and a "cleaner," the key being how you control it.

● How can laser rust removal be performed without damaging the metal?

Exploiting differences in "ablation thresholds": Contaminants on metal surfaces (such as rust, paint, and oil) have a lower "ablation threshold" (the minimum energy density required to begin destruction). Intact metal substrates, on the other hand, have a higher ablation threshold.

Precise energy control: The operator adjusts parameters such as laser power, pulse frequency, and scanning speed to precisely control the laser energy density to be above the "contaminant ablation threshold" but below the "metal substrate ablation threshold." This allows the contaminants to absorb the energy and instantly vaporize or lift off, while the underlying metal is only slightly heated—not high enough to melt or undergo structural changes, thus protecting it.

● Under what circumstances can laser damage metal?

When using laser rust removal equipment for cleaning, the laser is likely to damage the metal if the following conditions occur:

Excessive power: The energy density exceeds the metal's ablation threshold, causing surface melting or perforation. Slow scanning speed: The laser stays in the same spot for too long, causing excessive heat accumulation and localized overheating.

Small beam focus: The energy is too concentrated, resulting in excessive energy density per unit area.

Processing highly reflective or low-melting-point metals: Metals such as aluminum, copper, and zinc, which have high laser reflectivity or low melting points, are more susceptible to damage from uneven energy absorption or overheating.

Processing galvanized coatings: The laser may vaporize the zinc layer, destroying its corrosion protection.

In applications such as laser rust removal, scientific "threshold control" and precise parameter adjustment enable selective removal of surface contaminants while preserving the metal substrate intact. Therefore, whether a laser damages the metal depends not on the laser itself but on how it is controlled by the user. Professional laser rust removal equipment and trained operators are key to ensuring rust removal without damaging the substrate.

VII. What Precautions Should Be Taken When Using Laser Rust Removal Equipment for Cleaning?

In practical applications, safety is the primary principle. Operators must wear special laser safety glasses to protect their eyes from the high-energy beam, and an exhaust system should be installed to collect harmful fumes and dust generated during cleaning to prevent inhalation.

Also, parameters such as laser power and scanning speed should be precisely adjusted according to the workpiece material and degree of rust to avoid damaging the metal substrate due to excessive energy. This is especially important when processing galvanized or thin-walled parts.

The cleaned metal surface is extremely clean, but it is also highly susceptible to reoxidation. Painting or anti-corrosion treatment should be performed as soon as possible to ensure optimal results.

Laser rust removal is a revolutionary metal surface treatment technology. Its efficiency, environmental friendliness, precision, and safety are gradually replacing traditional sandblasting and chemical cleaning methods. Despite a high initial investment, its long-term benefits, automation potential, and environmental impact make it an indispensable cleaning tool in the industrial sector. Whether maintaining large steel structures or repairing precision parts, laser rust removal systems offer cleaner, smarter, and more sustainable solutions. Choosing the right laser rust removal equipment and mastering the correct operating procedures are essential for effective metal cleaning.