Laser Wood Cleaning

2025-11-20Since ancient times, wooden products have been an important part of human daily life. Whether it's rustic and elegant wooden furniture or exquisitely carved wooden art pieces, they silently record the passage of time and convey the charm of nature with their warm texture and natural grain. However, with the increase of use, the surface of wooden products inevitably accumulates dust, stains, and even stubborn graffiti. These not only damage their appearance but may also accelerate the aging and deterioration of the wood. Traditional cleaning methods, such as manual wiping or physical sanding, can remove stain

s to some extent, but they are often inefficient, time-consuming, and laborious, and can easily scratch or damage the wood surface, causing irreversible secondary damage. With the development of green manufacturing and precision cleaning technology, laser cleaning, as a non-contact, consumable-free, environmentally friendly, and efficient surface treatment method, is gradually being applied to traditional materials—including heat-sensitive and structurally complex wood products. So, are laser cleaning machines really suitable for wooden products? What stains can it remove? And what precautions should be taken? This article will comprehensively analyze the application of laser cleaning machines in the field of wooden products and the precautions from multiple perspectives.

I. How Does Laser Cleaning Machine Work on Wood Surfaces?

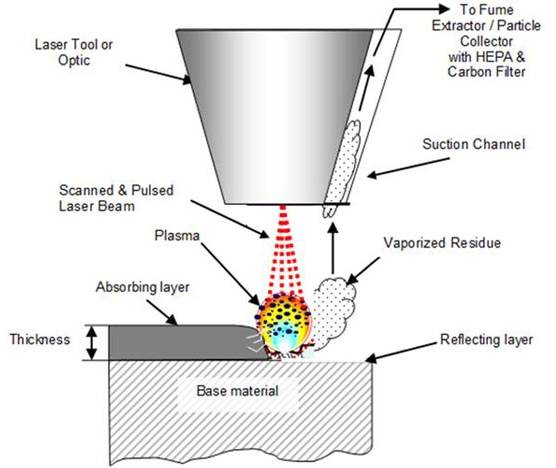

The core principle of laser cleaning of wood products is to use a high-energy pulsed laser beam to irradiate the surface of the wood object. This causes contaminants (such as dust, oil, paint, and mold) to absorb the laser energy in a very short time, rapidly heating up, vaporizing, or peeling off, thus separating them from the substrate. Wood itself has certain reflective or transmissive properties to lasers of specific wavelengths and energy densities. If the parameters are properly controlled, the laser can skip the wood itself and act only on surface contaminants, achieving a satisfactory cleaning effect.

II. What Types of Stains Can Laser Cleaning Machines Remove from Wood Products?

With the continuous expansion of laser applications, laser cleaning technology, with its non-contact, chemical-free, and precisely controllable characteristics, has demonstrated unique advantages in the fields of cultural relic preservation, furniture restoration, and high-end wood product cleaning. Although wood itself is relatively sensitive to lasers (easily ablated and discolored), by precisely controlling the laser wavelength, energy density, pulse frequency, and scanning speed, you can effectively remove various surface contaminants without damaging the substrate. Laser cleaning has excellent removal effects on the following common wood product surface contaminants:

● Organic stains: such as fingerprints, oil stains, food residue, wax residue, etc.;

● Aging coatings: partial or complete peeling of old coatings such as varnish, paint, and wood wax oil;

● Smoke and carbonization residues: soot and carbon black on the surface of wood after a fire;

● Mold and biological contamination: mold and algae that grow in humid environments;

● Glue residue and sticker residue: adhesive residue after removing labels;

● Oxidized discoloration layer: yellowing or dulling of the surface due to long-term exposure.

Laser cleaning is suitable for removing non-penetrating, highly absorbent surface contaminants from wood products, such as dust, soot, mildew, old paint, and graffiti. Its core value lies in its precision, non-destructive nature, and lack of chemical residue, making it particularly suitable for cleaning and restoring high-value wooden artifacts such as antique furniture, wood carvings, and historical architectural components. However, for penetrating stains such as oil and deep stains, you will still need to combine laser cleaning with other methods depending on the specific situation.

III. Advantages of Laser Cleaning for Wood Products

Compared to traditional cleaning methods such as water washing, chemical solvent wiping, and mechanical sanding, wood laser cleaning technology offers several significant advantages in wood product processing, especially suitable for scenarios with high requirements for surface integrity, historical value, or fine structure. The core advantages are as follows:

● Non-contact cleaning: No brushing or sanding is required, avoiding fiber tearing, texture wear, or patina damage caused by traditional sanding; particularly suitable for areas difficult to handle manually, such as carved details, openwork structures, and fragile antique wooden pieces.

● No chemical reagents: No need to use acids, alkalis, paint removers, alcohol, or other chemical solvents, eliminating solvent penetration, corrosion, or odor residue, making it particularly suitable for food-grade wood or cultural relics.

● High precision and controllability: By adjusting laser parameters (wavelength, energy, pulse width), you can selectively clean localized areas, preserving the original patina or historical traces. It can precisely remove localized smoke marks, old paint patches, or graffiti while retaining the surrounding original surface craftsmanship.

● Environmentally friendly and efficient: No volatile organic compound (VOC) emissions, no wastewater, waste sand, or dust emissions, meeting green manufacturing standards.

These unique advantages make laser cleaning uniquely valuable in fields such as wood carving art, high-end furniture restoration, ancient building maintenance, and musical instrument care.

IV. Precautions When Using Laser Cleaning for Wood Products?

While laser cleaning offers significant advantages for cleaning wood products, wood is a heat-sensitive, porous, and complex natural organic material, extremely sensitive to laser energy. Improper parameter settings or incorrect operation can easily cause irreversible damage such as discoloration, carbonization, cracking, or even burning. Therefore, in practical applications, we must strictly adhere to the following key precautions:

1. Strictly Control Laser Energy Density

Wood has a low ablation threshold (typically 0.5–2 J/cm², varying depending on the tree species); exceeding this value will result in rapid carbonization. Therefore, in actual operation, you need to strictly adhere to one principle: start testing with the lowest effective energy, gradually fine-tuning it, erring on the side of lower rather than higher. It is recommended to use pulsed laser cleaner (such as nanosecond/picosecond fiber lasers) to avoid prolonged continuous laser heating.

2. Prioritize Small-Scale Testing

Before performing formal laser cleaning of wood products, please conduct a trial cleaning on a concealed area or a scrap of the same material. Carefully observe for any phenomena such as yellowing, blackening (mild carbonization), fiber lifting or blurred texture, odor, or smoke (overheating signal). Record the optimal parameters such as power, frequency, scanning speed, and focal length for subsequent operations.

3. Adjusting the Process Based on Wood Type

Because different types of wood respond significantly differently to lasers, we need to adjust the laser cleaning process according to the type and characteristics of the wood:

● Hardwoods (such as oak, walnut, and rosewood) have high density and good heat resistance, offering a wider laser parameter window and relatively safer operation;

● Softwoods (such as pine, cedar, and poplar) contain more resin, have low thermal conductivity, and are flammable, requiring a lower energy density to prevent resin melting or combustion;

● Oily or waxy woods (such as teak and ebony) have surface oils that easily carbonize when heated, so laser cleaning should be used with caution. Local degreasing is recommended beforehand to reduce risk.

4. Ensuring Good Ventilation and Fume Control

Laser vaporization of contaminants produces fine particles and volatile organic compounds. Therefore, we must equip the system with a high-efficiency exhaust system and fume filtration devices (such as HEPA filters). In addition, operators should wear protective eyewear and dust masks to prevent inhalation of harmful fumes.

5. Unattended or prolonged continuous operation is prohibited. When using a laser cleaning machine for wood products, localized overheating of the wood may cause smoldering or open flames, especially during high-power operations. Therefore, we recommend using intermittent scanning to avoid repeatedly irradiating the same area. Furthermore, fire blankets or carbon dioxide fire extinguishers should be readily available on-site to prevent injury from accidents.

Laser cleaning of wood products is a delicate process combining technology and art. Only by fully understanding the characteristics of wood, the nature of stains, and the mechanism of laser action can the ideal effect of "removing stains without damaging the wood, and restoring its original appearance without distortion" be truly achieved. For valuable furniture, cultural relics, or works of art, it is recommended to entrust the process to a professionally qualified restoration organization.

V. What is the Impact of Laser Cleaning on the Lifespan of Wooden Products?

As a modern surface treatment technology, laser cleaning, when applied scientifically and according to regulations, not only does not shorten the lifespan of wooden products, but can actually effectively extend their lifespan and improve their preservation condition. However, improper operation may cause irreversible damage and accelerate aging. Its impact on the lifespan of wooden products is "two-sided," and the key lies in the precision of process control and the appropriateness of the application scenario.

Under correct process parameters, laser cleaning has positive effects on the maintenance of wooden products:

● Removes biological contaminants such as mold and insect eggs, reducing the risk of decay;

● Facilitates the recoating of protective layers after removing aged coatings, improving protective performance;

● Eliminates mechanical stress, avoiding fiber breakage or structural weakening caused by traditional sanding;

● The clean, dry, and oil-free surface after cleaning is conducive to the effective penetration and adhesion of protective materials such as anti-mold agents, reinforcing agents, and sealing waxes.

However, improper operation leading to surface carbonization or microcracks can accelerate moisture penetration and the aging process:

● Thermal damage causing fiber carbonization or embrittlement: Excessive laser energy or slow scanning speed can cause localized temperatures on the wood surface to exceed 300°C, resulting in surface blackening, brittleness, blurred texture, and loss of luster.

● Causing microcracks or stress concentration: Rapid heating and cooling processes can generate thermal stress on the wood surface, especially at the junctions of growth rings or in areas with existing microcracks; repeated improper cleaning over a long period can accumulate damage and reduce structural stability.

● Altering the chemical properties of the wood surface: Excessive laser irradiation may cause the formation of carbonyl and carboxyl groups on the surface, increasing hydrophilicity; this makes the wood more susceptible to moisture absorption, accelerating subsequent aging cycles.

● Inadvertently erasing historical information and reducing the value of cultural relics: For antique furniture or cultural relics, the patina and signs of use are themselves historical evidence; excessive laser cleaning, while giving the surface a "brand new" appearance, loses the unique value bestowed by time, which is actually "damage" from a cultural lifespan perspective. Therefore, professional laser cleaning operation and parameter optimization are crucial.

VI. What Types of Wood Products Are Suitable for Laser Cleaning?

Laser cleaning is not suitable for all types of wood products. Its applicability depends on the type of wood, its structural condition, surface condition, historical value, and the type of stain. Under the premise of scientific evaluation and precise parameter control, the following types of wood products are suitable for laser cleaning technology:

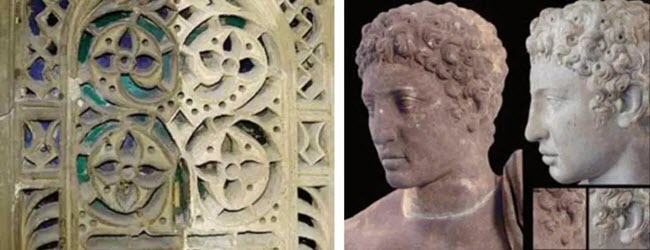

● Antique furniture and cultural relic wood carvings: Fine cleaning without damaging the historical patina;

● High-end solid wood furniture: Removal of surface stains from transportation or use;

● Musical instruments (such as guitar and piano cases): Preserving sound quality from chemical contamination;

● Building wooden components: Refurbishment and maintenance of beams, columns, doors, windows, and floors;

● Handicrafts and wooden toys: Meeting safe and non-toxic cleaning requirements;

● Fire-damaged wood: Effectively removing smoke and carbon layers and assessing structural integrity.

For softwoods (such as pine and cedar) or woods with high resin content, extra care must be taken to control the laser energy; while hardwoods (such as walnut, teak, and oak) generally have better tolerance and better cleaning results.

Laser cleaning machines for wood products not only effectively remove various stains from wood surfaces, but also bridge the gap between traditional wood preservation and modern intelligent manufacturing with their precision, cleanliness, and environmental friendliness. While their application relies on specialized laser equipment and experienced operation, with the popularization of technology and the maturation of processes, laser cleaning is becoming a revolutionary tool in the field of wood product cleaning and repair—preserving the natural beauty of wood while extending its practical value and cultural life. In the future, with continuous technological innovation and the expansion of application scenarios, laser cleaning machines will undoubtedly shine in a wider range of fields, bringing more convenience and unexpected surprises to our lives. If you would like to learn more about wood cleaning tips or wood laser cleaning machine, please feel free to contact us.