Laser Marking VS. Laser Engraving

2025-12-24If you've recently been researching laser processing equipment, or are planning to personalize your products, you've likely heard the terms "laser marking" and "laser engraving." At first glance, they seem similar—both use lasers to "write" or "draw" on surfaces. While both use lasers, they perform very different tasks. Laser marking and laser engraving both utilize laser beams to process material surfaces, but they differ significantly in their principles, effects, applications, and applicable materials. Let's explore the differences between laser marking and laser engraving.

I. What is Laser Marking?

Laser marking uses a high-energy laser beam to act on the surface of a material, causing physical or chemical changes—such as oxidation, foaming, or discoloration—to create high-contrast, durable, and clear markings. Depending on the material's properties, common marking methods vary: annealing marking is often used on metals, forming an oxide layer through localized heating to produce color changes; on organic materials (such as wood or paper), carbonization is frequently used, causing the surface to slightly char and blacken; and in plastics, foam marking uses a laser to induce the release of gases from within the material, creating light-colored raised marks. All these methods can achieve fine and permanent marking effects without significantly damaging the substrate.

II. What is Laser Engraving?

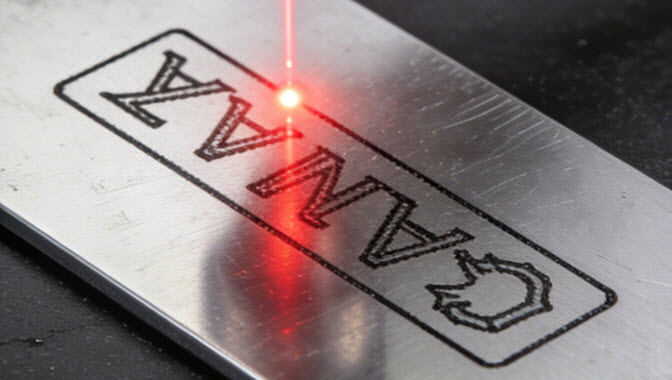

Laser engraving uses a high-energy-density laser beam to directly act on the surface of a material, removing some of the material through ablation or vaporization, thereby creating deep, recessed patterns, text, or textures. Unlike marking, which only changes surface properties, engraving essentially involves physical removal of material, thus producing a distinct three-dimensional effect and tactile feel. It is suitable for applications requiring high visual impact and detail, such as crafts, advertising signage, and personalized customization.

III. What is the Difference Between Laser Marking and Laser Engraving?

▌ Laser Marking VS. Laser Engraving in Depth

The most obvious difference between laser marking and laser engraving is the depth.

Laser marking is more like "makeup" on the material surface. It doesn't actually remove much material, but rather uses a laser to cause color changes, oxidation, foaming, or slight carbonization of the surface layer, creating a clearly visible mark. When you touch it, it's basically flat, with little texture. Laser engraving, on the other hand, is much more "ruthless"—it actually "burns" away layers of material, carving out real grooves. You can not only see it, but you can also feel it! For example, the three-dimensional effect of a name on wood or text on an acrylic trophy is achieved through engraving. Simply put, laser marking changes color/appearance (shallow layer), while laser engraving removes material (deep layer).

▌ Laser Marking VS. Laser Engraving in Application Scenarios

Don't underestimate the difference between "shallow" and "deep" marking; it directly determines the application scenarios of laser marking and laser engraving.

Laser marking prioritizes "precision, permanence, and non-damage to the original material," making it highly favored in the industrial sector. For example, serial numbers on medical devices must be persistently clear and not affect sterility; QR codes on internal metal parts of mobile phones must be scannable without creating protrusions that could interfere with assembly; and traceability codes on aerospace parts must withstand high temperatures and corrosive environments—these applications demand highly reliable marking while strictly prohibiting damage to the part's structure, making laser marking the preferred choice.

In contrast, laser engraving focuses more on the "visible and tangible" visual and tactile effects, commonly found in customized gifts (such as pens engraved with names, couple's mugs), advertising signs (such as acrylic lettering, wooden logos), and artistic creations (such as reliefs, patterns, and textures). Here, the depth of engraving is not a defect, but rather a key advantage in creating a sense of layering and texture.

▌ Laser Marking VS. Laser Engraving in Laser Source

While many devices on the market claim to "both mark and engrave," the choice of laser source for professional applications still depends on the specific materials and process requirements.

Fiber lasers are the preferred choice for metal marking, especially excelling on materials such as stainless steel and aluminum alloys—high speed and high precision have made them the mainstay of industrial marking. CO₂ lasers, on the other hand, are more advantageous in processing non-metallic materials, widely used for engraving on materials such as wood, leather, and acrylic, achieving delicate and smooth pattern effects. For high-precision, low-heat-affected scenarios, such as fine marking on plastic or glass surfaces, ultraviolet lasers stand out due to their "cold processing" characteristics, leaving almost no trace of heat damage.

Therefore, if your primary task is marking on stainless steel nameplates, a CO₂ laser machine is clearly unsuitable; conversely, if you want to engrave on wood, fiber lasers are often "powerless" because they cannot effectively work on non-metallic materials. Choosing the right laser source is crucial for achieving optimal results.

▌ The Differences in Speed and Cost

There are significant differences in speed and cost between laser marking and laser engraving.

Marking typically only requires a light scan of the material surface, completing the marking of a part in a few seconds, making it extremely efficient. Engraving, on the other hand, requires repeated scans, ablating or vaporizing the material layer by layer, especially for deep engraving, which can increase the time significantly.

Therefore, in mass industrial production, marking is a more efficient and economical choice, while engraving is mostly used in personalized customization scenarios where visual effects and tactile feel are important. From an equipment investment perspective, high-power laser engraving machines are not only more expensive but also more complex to maintain; in contrast, fiber laser marking machines offer superior cost-effectiveness and are more suitable for production line applications that prioritize efficiency and cost control.

▌ Laser Marking and Laser Engraving: Which Should You Choose?

When selecting equipment, how should you choose between laser marking and laser engraving? Here, we share a quick method to determine whether to choose laser marking or laser engraving. Ask yourself two questions:

1. Do I need this mark to be tactilely discernible?

2. Can a portion of the material itself be removed?

If the answer is "no need to be tactilely discernible" and "cannot damage the structure," such as for permanent marking on precision metal parts or medical devices, then choose laser marking. However, if you are seeking a distinct three-dimensional effect and texture, and the material itself (such as wood, acrylic, or leather) allows for partial removal, then laser engraving is a more suitable choice. This simple method can help you quickly match your process and needs.

Ultimately, laser marking and laser engraving are not inherently superior or inferior; they simply have different strengths and functions. Their relationship is like that of a pencil and a carving knife—one excels at precisely "writing" on a surface, while the other specializes in deeply "carving" into materials. Using them correctly is true technological wisdom. Hopefully, this article will provide you with some valuable information. If you are selecting equipment or developing a process plan, take some time to clarify your actual needs—do you require permanently clear markings, or a tactile, three-dimensional effect? Thinking this through before deciding on a technology will not only save you money but also avoid unnecessary trial and error and wasted time.