Automated Laser Marking Solutions

2025-05-29Laser marking machines are not common in our daily lives, but the products marked by laser marking machines are everywhere in our lives, such as water cups, coffee cups, faucets, machine nameplates, jewelry, watches, medical devices, etc. In fact, laser marking can be seen everywhere in our daily lives and in the field of industrial manufacturing. Laser marking is a high-precision, high-efficiency and eco-friendly technology. It has been widely used in many fields to mark a wide variety of materials, identify patterns, text, barcodes, QR codes, etc. It plays an indispensable role in improving product quality, safety and brand awareness. In this article, we share with you automated laser marking solutions, such as metal marking solutions, and introduce the working principle, advantages and characteristics of laser marking, applicable materials, industry applications, future development trends, etc. If you are interested in this or are looking for laser marking systems, this article may give you some clues.

I. What is Laser Marking

Laser marking is a process that uses a high-energy-density laser beam to permanently mark the surface of a material. By controlling the focus point and scanning path of the laser, various forms of marking such as text, numbers, patterns, QR codes, and barcodes can be achieved on the surface of the workpiece.

Compared with traditional mechanical engraving, ink printing and other methods, laser marking does not require contact with the workpiece, does not cause consumable wear, and has clear, beautiful marks and strong durability.

II. The Working Principle of Laser Marking

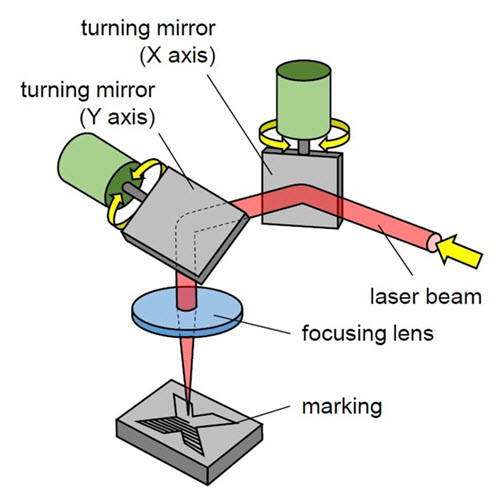

The basic principle of laser marking is to use the high-energy laser beam generated by the laser, which is focused by the optical system and irradiated on the surface of the material, causing physical or chemical changes in the material, thereby forming a visible mark. The specific process details are as following:

Laser emission: the laser generates a laser beam of a specific wavelength.

Optical path transmission: the laser is guided to the focusing lens through components such as reflectors and galvanometers.

Focusing effect: the focusing lens focuses the laser beam on a small area, causing the surface of the material to heat up rapidly.

Material reaction: depending on the laser parameters, the material may evaporate, oxidize, carbonize or change color, forming the required mark.

III. Types of Laser Marking Technologies

According to the different laser media and working mechanisms, common laser marking technologies mainly include the following categories:

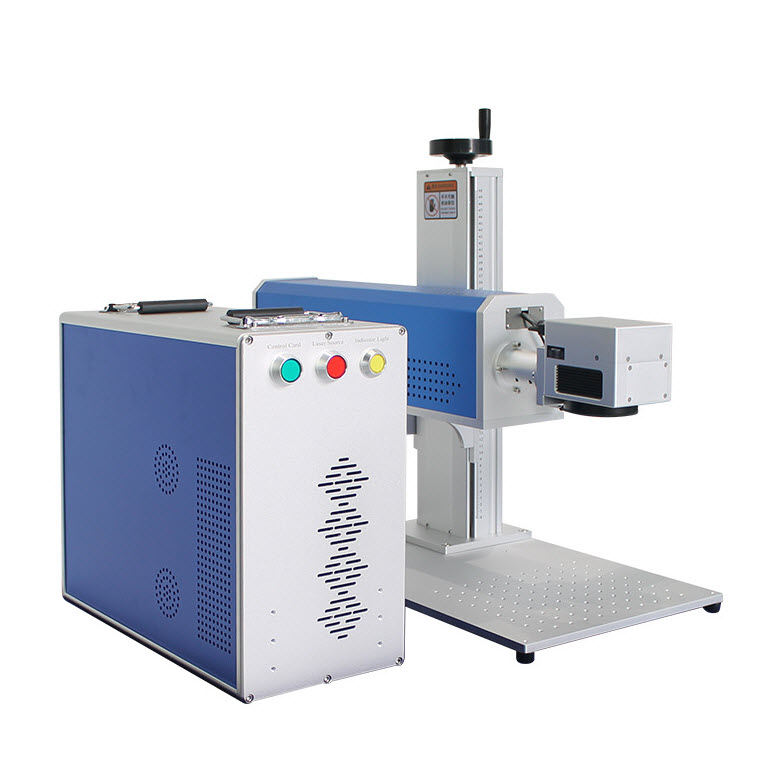

1. Fiber laser marking solution

Fiber laser marking machine, with wavelength 1064nm, uses laser beam to mark permanently on the surface of various materials. The effect of marking is to expose the deeper material through the evaporation of the surface material, or to carve out traces through the physical change of the surface material caused by light energy, or to burn off part of the material through light energy to reveal the desired etching pattern, text, barcode and other graphics. It is widely used for marking metal materials and some non-metallic materials such as plastic, ceramic and etc. in various fields like automotive, aerospace, electronics and so on.

2. CO2 laser marking solution

The CO2 laser marker uses carbon dioxide gas as the working medium. It generates a laser with a wavelength of 10.64um through high-voltage discharge. After scanning and focusing by a galvanometer, it marks the surface of the workpiece. It is suitable for various non-metallic materials and some metal products. It is suitable for a wide range of materials such as wood, glass, acrylic, leather, cloth, paper, plastics etc. CO2 laser markers are widely used in the packaging, textile, arts and crafts and more industries.

3. Ultraviolet laser marking solution

Its wavelength is usually 355nm. As the UV laser marker has a very small focused spot and the processing heat affected zone is minimal, the UV laser marker can perform ultra-fine marking and special material marking. It is widely used for marking sensitive materials such as precision electronic components, glass, ceramics, plastics and etc.

4. Semiconductor laser marking solution

It is using semiconductor materials as pump sources, featuring high marking efficiency, high precision and small size. It can mark metal and various non-metal materials, particularly suitable for electronic components, hardware products, tool accessories, integrated circuits (ICs), electrical appliances, mobile communications, precision instruments, glasses and watches, jewelry, auto parts, plastic buttons, building materials and etc.

5. MOPA laser marking solution

MOPA laser marker uses MOPA (adjustable pulse width) fiber laser. It has good pulse shape control capability. Compared with Q-switched fiber laser, MOPA fiber laser pulse frequency and pulse width are independently controllable. Through the adjustment of two laser parameters, it can achieve constant high peak power output and can be applied to a wider range of materials. MOPA laser marking machine is mainly used in stainless steel color marking, aluminum oxide blackening, anode stripping, coating stripping, semiconductor and electronics industry, plastic and other sensitive material marking and PVC plastic pipe industry.

IV. Advantages of Laser Marking When Compared with Traditional Marking Methods

As a modern precision processing method, laser marking technology has the many outstanding advantages compared with traditional marking methods such as corrosion, EDM, mechanical engraving, and printing:

1. Laser is used as a processing method, and there is no processing force between the laser and the workpiece. It has the advantages of no contact, no cutting force, and small thermal impact, which ensures the original precision of the workpiece. At the same time, it has a wide adaptability to materials, and can make very fine marks on the surface of a variety of materials with very good durability.

2. The laser has good spatial controllability and temporal controllability, and has a large degree of freedom in the material, shape, size and processing environment of the processing object, which is particularly suitable for automated processing and special surface processing. And the processing method is flexible, which can meet the needs of laboratory-style single-item design and the requirements of industrial mass production.

3. The laser mark is fine, and the lines can reach the millimeter to micron level. The marks made by laser engraving technology are very difficult to imitate and change, which is extremely important for product anti-counterfeiting.

4. The combination of laser processing system and computer numerical control technology can form efficient automated processing equipment, which can print various texts, symbols and patterns, and is easy to design and engrave patterns with software, change the marking content, and adapt to the high efficiency and fast pace requirements of modern production.

5. Laser processing has no pollution source and is a clean and pollution-free high environmental protection processing technology, while other laser marking methods have metal scraps, chemical ink evaporation or waste acid and etc.

V. What Kinds of Materials Can Be Marked with Laser

As a high-quality laser marking solution, it has been widely used in many industries to mark barcodes, logos, brand logos, nameplates, production dates, patterns, etc. It can be applied to a variety of materials:

1. Leather

Using laser marking technology, you can easily mark various designed patterns, brand names and other styles clearly, beautifully and quickly on various leather products, such as leather clothing, bags, shoes, wallets, etc. From the softest deerskin to the hardest cowhide, laser marking uses computer-controlled equipment with pre-programmed patterns to complete this operation, ensuring the highest accuracy even in the most complex tasks. The leather materials are as follows:

Suede (sheepskin), Genuine leather, Synthetic leather, Recycled leather, Nubuck leather, Alcantra leather, Suede leather and Top layer leather.

2. Wood

With laser marking solutions, you can easily and conveniently mark beautiful, delicate, good-feeling, fine and clear icons, text, lines, etc. on wood products:

Cork, Veneer, Natural wood, Solid wood, Plywood, Particleboard, HDF, MDF and Composite board.

3. Paper

Laser marking can also be used to mark the pictures or texts you want on various cardboards, art papers, etc., such as greeting cards, business cards, labels, book covers, etc., to meet your various brand or information delivery needs.

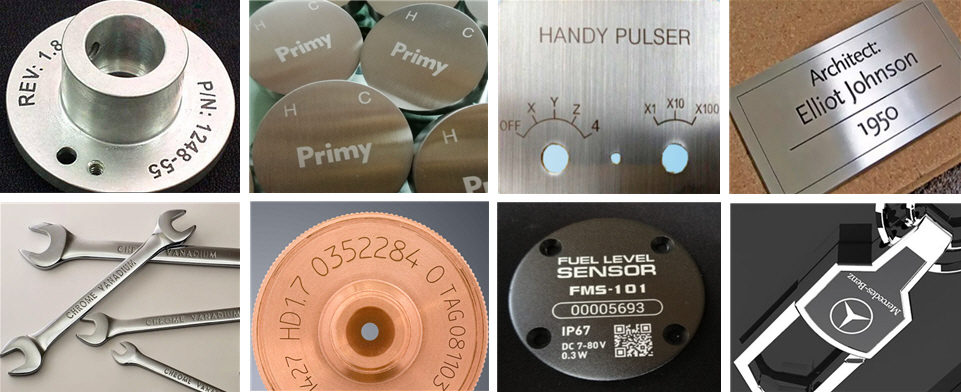

4. Metal

Laser marking is widely used on a variety of metal materials, and it is also very suitable for marking high-precision, durable, burr-free logos, photos or texts on metal workpieces of different hardness, such as mechanical gears, auto parts, hardware tools, locks, medical equipment, accessories, etc. Whether it is a single part or a small batch production, it is an ideal choice, which can not only improve marking efficiency but also ensure consistent results. These materials include:

Gold, Titanium, Copper, Brass, Stainless steel, Steel, Aluminum, Iron and Silver.

5. Plastics

Laser marking equipment can also help you achieve exquisite marking on a variety of plastic products, such as wires, sleeves, buttons, lamp holders, animal ear tags, components, water cups, etc. It helps you complete high-contrast marking at very high speeds without any negative impact on surface quality. The plastic materials are as following:

Polyethylene, Silicone, Vinyl, Acrylic, Polycarbonate and Polyester.

6. Glass

Glass products play an important role in our lives. If the glass cups, glass coffee tables, glass decorations, glass tableware, mirrors, car glass, etc. in life. Laser marking technology is very suitable for marking the text and patterns you want on various glass products. In order to adapt to the transparency and fragility of glass, laser marking can provide you with flexible marking methods, such as laser micro crack technology, laser peeling coating, etc., to help you achieve fine marking without micro cracks on glass products.

7. Stone

In the past, the more common stone processing methods include grinding, sandblasting, and carving, but these processing methods have some shortcomings in practical applications, such as high labor consumption, low product consistency, and insufficient processing precision. With the application and exploration of laser marking machines in the jade processing industry, laser marking machines have been able to effectively solve some problems. For example, the laser marking process eliminates the processes of engraving, stickers, sandblasting, and paper removal. The narrow line width and high peak power in laser processing can control cracks within a range that cannot be observed by the naked eye. Therefore, the stone processing industry has also greatly benefited from laser marking technology. Through laser marking technology, you can achieve perfect identification on stone products, such as pictures, lines, text, etc. These stones include:

Marble, Granite, Artificial marble slabs, Natural stone and Ceramics.

If you are looking for high-quality laser marking machines or solutions, please feel free to contact us. We will be happy to answer any questions you have or provide the best laser marking solutions.