Fiber Laser Welding Aluminum

2025-05-20With the continuous improvement of modern manufacturing industry's requirements for material properties and processing efficiency, aluminum alloy, as a lightweight, high-strength and corrosion-resistant metal material, is widely used in aerospace, automobile manufacturing, electronic equipment and new energy fields. However, due to its high reflectivity, strong thermal conductivity and easy oxidation, the traditional welding process of aluminum alloy faces many challenges. In recent years, fiber laser welding technology has gradually become an important solution in the field of aluminum alloy welding with its unique advantages. In this post, we will share the advantages and application cases of aluminum laser welding with you.

1. Overview of fiber laser welding technology

Fiber laser welding is an advanced welding method that uses a high-energy-density laser beam as a heat source to locally heat metal materials to a molten state and achieve connection. Compared with traditional CO₂ lasers, fiber lasers have higher photoelectric conversion efficiency, better beam quality and more stable output performance, and are particularly suitable for precision and high-speed welding.

2. Advantages of fiber laser welding aluminum alloys

• High energy density and strong deep melting welding ability: Fiber lasers can provide extremely high energy density, which can quickly melt or even vaporize the surface of aluminum alloys to form a "keyhole effect", thereby achieving deep and narrow welds and significantly improving welding strength and sealing.

• Fast welding speed and high production efficiency: Compared with traditional TIG or MIG welding methods, fiber laser welding is faster, with lower heat input, reducing the heat affected zone (HAZ), and effectively avoiding weld deformation and grain coarsening problems.

• Non-contact processing and high precision: Laser welding does not require physical contact and can achieve micron-level positioning, which is suitable for precision welding of complex structural parts, especially for automated production line integration.

• Strong adaptability and compatibility with a variety of aluminum alloy materials: Fiber lasers can flexibly adapt to different grades of aluminum alloys (such as 6061, 5052, 7075, etc.) by adjusting power and pulse parameters to meet diverse industrial needs.

3. Application fields

In daily life and industrial manufacturing, aluminum alloys are important components of many items, such as electric vehicle battery packs, aircraft structures, mobile phone shells, laptop computer shells, etc. Therefore, aluminum welding technology is particularly important. The quality of welding directly determines the stability and safety of the product's electrical connection, structural strength and fatigue life, sealing performance, appearance effect, etc. Due to the unique advantages of fiber laser welding, it is widely used in new energy vehicles, aerospace, consumer electronics manufacturing and other fields to achieve high-quality joining and precision high-speed welding.

• Note: In the actual operation process, it is difficult to optimize the process parameters of aluminum alloy laser welding. It is necessary to continuously adjust the power, speed, defocus and other parameters for different thicknesses and types of aluminum alloys to obtain the best welding quality.

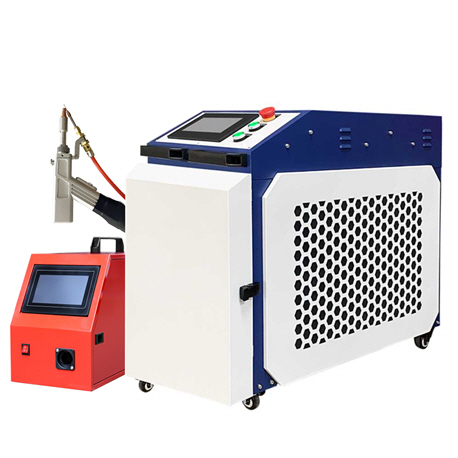

Fiber laser welding technology is becoming the mainstream choice in the field of aluminum alloy welding with its high efficiency, high precision and good adaptability. With the continuous advancement of technology, its application prospects in emerging industries such as new energy and intelligent manufacturing are broad. For enterprises, mastering the core technology of fiber laser welding will help improve product quality, reduce production costs and enhance market competitiveness. If you are interested in NITRATEK aluminum fiber laser welding machine, please contact us for more details and we will offer the most preferential price for you.