Metal Fiber Laser Marking

2025-05-21In modern industrial manufacturing, product identification has become an indispensable part. Whether it is used for traceability, anti-counterfeiting, brand display or process description, clear and permanent marking is essential. In recent years, with the continuous advancement of laser technology, metal fiber laser marking technology has been widely used in surface marking of various metal materials with its high precision, high efficiency and stability, and plays an important role in the automotive, electronics, medical equipment, aerospace and other industries. In this case, we will share with you the principles, advantages and some successful application cases of metal laser marking.

I. What is Metal Fiber Laser Marking?

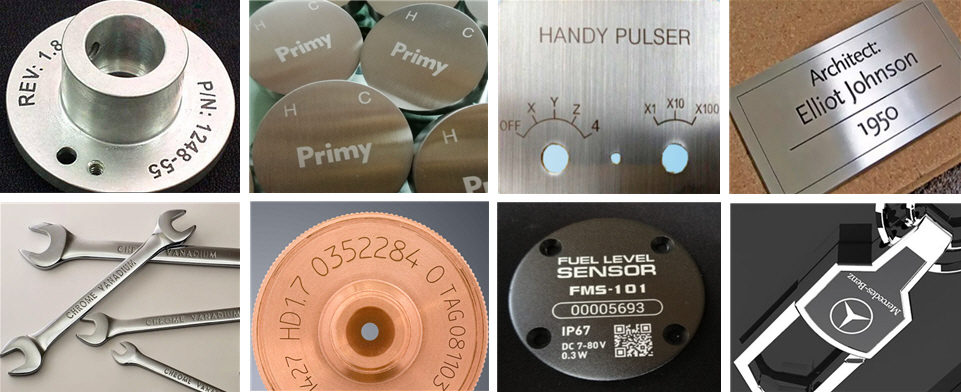

Metal fiber laser marking is a non-contact processing method that uses a high-energy-density fiber laser beam to locally irradiate the surface of a metal material to cause physical or chemical changes on the surface, thereby forming a permanent mark. Common marking contents include text, numbers, QR codes, barcodes, logos, patterns, etc. The core component of the fiber laser marking machine is the fiber laser, which uses a fiber doped with rare earth elements (such as ytterbium) as a gain medium to generate a stable laser beam with excellent focusing performance, which is particularly suitable for fine marking of metal materials.

II. Advantages of NITRATEK Metal Laser Marking System

Clear marking and strong permanence: Fiber laser marking can achieve high-contrast, high-resolution marking effects on metal surfaces, and can remain clear and non-fading even in high temperature, humid or corrosive environments, which is very suitable for product identification that needs to be preserved for a long time.

Non-contact processing, no mechanical wear: During the laser marking process, there is no need for the tool to contact the workpiece, avoiding the problems of scratches and deformation that may be caused by traditional mechanical engraving, while reducing equipment maintenance costs.

Fast processing speed and high production efficiency: Compared with traditional inkjet printing or mechanical engraving, fiber laser marking is faster, especially suitable for large-scale, automated production line applications.

Wide range of applicable materials: The metal laser marking system can be used for marking a variety of metal materials: such as stainless steel, carbon steel, aluminum alloy, copper alloy, titanium alloy, etc., to meet the needs of different industries for material diversity.

Environmental protection and energy saving, low operating cost: The laser marking process does not require the use of ink or solvents, does not produce harmful substances, and conforms to the concept of green manufacturing. At the same time, fiber lasers have low power consumption, long life, and high cost performance.

III. Typical Application Scenarios of NITRATEK Fiber Laser Marking Equipment

As an industry-leading manufacturer of metal laser marking machine systems, NITRATEK has a wide range of products. In addition to fiber laser marking machines, we have also developed CO2 laser marking machines and UV laser marking machines with reliable product quality. Our fiber laser marking machines have stable performance and high precision, so they are widely used in various industries for marking metal surfaces:

Electronic products industry: Precision coding or batch marking is often required on tiny components such as mobile phone casings, circuit boards, connectors, chips, etc. Fiber laser marking can easily achieve high-quality marking with micron-level accuracy.

Automotive industry: Key components such as engine parts, brake pads, sensors, and airbag components require uniqueness and traceability. Fiber laser marking technology can ensure that the information is clear and cannot be tampered with.

Medical device field: Medical devices have extremely high requirements for hygiene and safety. Laser marking can complete sterile identification without destroying the performance of the material, such as surgical instrument numbers, implant identification codes, etc.

Hardware tools and mold industry: various types of knives, measuring tools, molds, etc. need to be used for a long time. Fiber laser marking can provide wear-resistant and corrosion-resistant permanent markings for easy management and maintenance.

IV. Development Trends and Prospects of Metal Fiber Laser Marking

With the advancement of intelligent manufacturing and Industry 4.0, fiber laser marking technology is developing towards higher power, higher speed and higher integration. In the future, combined with automated control systems, visual positioning systems and artificial intelligence algorithms, metal fiber laser marking will be more intelligent and flexible, further improving processing efficiency and consistency. In addition, with the rapid development of emerging industries such as new energy, semiconductors, and precision instruments, the market demand for miniaturized and complex markings is growing, which also provides a broader application space for fiber laser marking technology.

With its excellent processing performance and wide applicability, metal fiber laser marking technology is gradually replacing traditional marking methods and becoming one of the indispensable and important processes in modern manufacturing. For companies that pursue quality, efficiency and sustainable development, choosing high-performance fiber laser marking equipment is not only a reflection of technological upgrading, but also a key step in enhancing core competitiveness. If you are interested in NITRATEK's metal fiber laser marking technology, or want to learn more about our metal laser marking equipment, please feel free to contact us.