Working Principle of CO2 Laser Marking Machine

The CO2 laser marking machine uses a 10.6um infrared laser generated by a carbon dioxide gas laser to accurately control the direction of the laser beam through a high-speed scanning galvanometer and focus it on the surface of the workpiece through a field lens. When the laser irradiates non-metallic materials such as wood, plastic, glass or leather, the surface of the material undergoes physical or chemical changes due to the thermal effect caused by local high temperature, thereby achieving fine and lasting marking. This process is efficient and accurate, and is suitable for a variety of industrial marking needs.

Multiple Models to Adapt to a Variety of Marking Application Scenarios

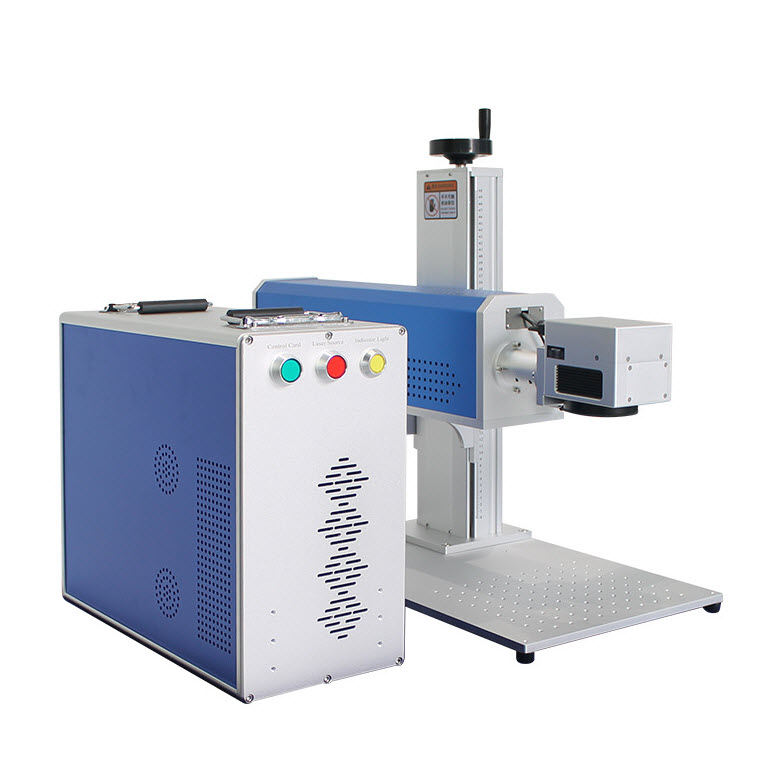

As a professional CO2 laser marking machine manufacturer, NITRATEK provides a variety of models (30W, 40W and 60W) and types of CO2 laser marking systems to meet the needs of different industries and application scenarios. Users can choose the appropriate power configuration according to the material type and processing requirements. Among them, the flying CO2 laser marking system is designed for continuous marking tasks on high-speed production lines to ensure efficient and stable marking effects. The all-in-one CO2 laser marking machine integrates all necessary components, is easy to carry and move, and is very suitable for on-site operations or small production environments. The split-type CO2 laser marking machine provides higher flexibility through a separate structural design, which is suitable for the processing needs of workpieces of various sizes. Desktop CO2 laser marker has a classic and durable cabinet design, which not only provides good protection, but also effectively isolates external dust and moisture to ensure the long-term stable operation of internal components. No matter what type of equipment you need, NITRATEK can provide you with efficient, reliable and flexible solutions to meet the diverse industrial marking needs.

Using High Quality Components and Parts

NITRATEK CO2 laser marking machine uses high-quality core accessories and advanced configurations to ensure the stability and durability of the equipment during long-term operation. These CO2 laser markers are equipped with high-performance CO2 lasers from brands such as DAVI, CRD or HAN's, with an output wavelength of 10.6um, which is particularly suitable for the fine processing of non-metallic materials such as wood, acrylic, leather, and cloth. The galvanometer system uses well-known brands such as Sino-Galvo or ZBTK. The beam diameter is less than 1.2mm, which can achieve high-precision line width marking of 0.01 to 0.1mm, reduce response delay, greatly improve marking speed, maintain high precision, and significantly improve marking clarity and detail performance. In terms of control system, the equipment is equipped with advanced control motherboard and user-friendly software interface, supports personalized customization, multi-format import (such as PLT, DXF, BMP) and fast maintenance and debugging, and is easy and efficient to operate.

Application Fields & Advantages of NITRATEK CO2 Markers

As an industry-leading CO₂ laser marking machine manufacturer, NITRATEK products have been widely used in many fields, especially for the fine processing of non-metallic materials such as wood, paper, plastic, glass, and leather. With its excellent performance of high speed and high precision, NITRATEK CO₂ laser marking machine has become an ideal marking solution for industries such as electronic components, packaging printing, advertising technology, and gift manufacturing. The equipment not only supports high-quality marking on flat materials, but also can achieve precise engraving of three-dimensional curved workpieces through a dynamic focusing system, expanding the scope of application and processing flexibility. Combining compact structural design, user-friendly operation interface and stable and efficient operation performance, this series of products significantly improves production efficiency while lowering the operating threshold, providing enterprises with truly efficient, intelligent and reliable laser processing solutions. Whether it is large-scale manufacturing of automated production lines or small-batch customization of creative studios, NITRATEK can provide machines that match the needs to meet the laser marking needs in various scenarios.