Working Principle of UV Laser Marking Machine

UV (ultraviolet) laser marking machine realizes non-contact precision processing by emitting high-energy UV laser beams (usually with a wavelength of 355nm). After the laser beam is expanded, scanned and focused by the optical system, it acts on the surface of the material with micron-level precision, and removes the surface material through photochemical reactions (such as molecular bond breaking) or thermal effects (such as material evaporation/oxidation), thereby forming a permanent, high-precision mark. UV laser marking has the characteristics of short wavelength and high energy density, which can realize micron-level fine processing and is suitable for scenes with extremely high precision requirements.

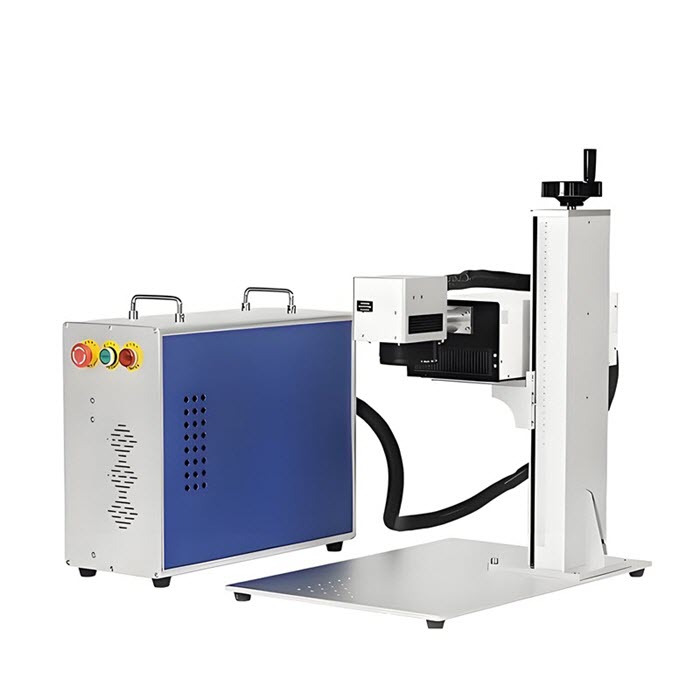

Advantages of NITRATEK Ultraviolet Laser Marking Machine

UV laser marker has become the core equipment in the field of industrial manufacturing due to its high precision, non-contact processing and wide material adaptability. Its laser wavelength is 355nm (deep ultraviolet band), and the minimum line width can reach 0.01mm, which can realize micron-level fine etching to meet the needs of precision scenes such as electronic components and medical devices. The equipment uses photochemical reaction or thermal effect to remove the surface of the material, avoiding deformation or damage caused by traditional thermal processing. It is especially suitable for fragile or heat-sensitive materials such as plastics, glass, ceramics, and metals. At the same time, UV laser marking systems do not require consumables (such as inks), have no pollution emissions, and meet environmental protection requirements. The intelligent air cooling system, water cooling system and precision optical design ensure long-term stable operation, and the modular structure (such as Flying mode, desktop models) supports flexible configuration, adapting to small-batch laboratory research and development to high-speed production line mass production. Whether it is 3W/5W/10W power selection or 70*70mm to 300*300mm marking area, it reflects its significant advantages in efficiency, accuracy and cost control.

High Quality Core Components and Parts

As an industry-leading UV laser marking machine manufacturer, NITRATEK adheres to strict standards for the selection of core component suppliers and only cooperates with high-quality brands, thereby effectively ensuring the high performance and stability of UV marking machine. UV lasers are from internationally renowned brands such as RFH Laser, HAN's Laser, PulseX Laser, and Gainlaser. The stability error of laser power (3W/5W/10W) is ≤5%, and the wavelength accuracy is controlled within the range of ±0.5nm, meeting the stringent requirements of precision machining for energy density and wavelength consistency. The galvanometer system uses high-precision optical drive brands such as Sino-Galvo and ZBTK, with positioning repeatability of ≤0.05mm and fast response speed, ensuring high-speed marking capabilities for complex graphics. NITRATEK conducts rigorous temperature cycling, vibration testing, and laser power attenuation experiments on each batch of parts to ensure their long life and anti-interference capabilities in industrial environments. This extreme control of the core supply chain is aimed at providing the best UV marking solutions for every customer.

Applications & Prospects of UV Laser Marking Machines

Ultraviolet laser marking machines have deeply penetrated multiple high value-added industries with their high precision, non-contact processing, and wide material adaptability. In the field of electronics and semiconductors, its 0.01mm line width can realize the miniaturization of chips and circuit boards, supporting the precision identification needs of 5G communications and IOT devices. The medical equipment industry relies on its sterile and corrosion-resistant marking capabilities to provide standard permanent identification for surgical instruments and implants. The consumer goods field enhances product value through anti-counterfeiting labels and personalized engraving, such as customized patterns of cosmetics and luxury goods. With the technological innovation of new energy, biomedicine and other industries, UV laser marking machines are developing towards higher power, smaller spot and intelligent control. NITRATEK 3W/5W/10W multi-power models, flying marking and modularly designed portable models can provide global customers with full-scenario solutions from laboratory research and development to mass production of production lines, helping companies seize the initiative in the field of high-precision manufacturing. When looking for a reliable UV laser marking machine manufacturer, NITRATEK can be your trusted partner.